Are there specific industries or applications where HIP-processed structural integrity is critical?

Are There Specific Industries or Applications Where HIP-Processed Structural Integrity Is Critical?

Aerospace and Aviation

In aerospace, HIP is indispensable for structural integrity in turbine components, engine casings, and flight-critical brackets. Materials such as Inconel 718 and Ti-6Al-4V benefit from HIP through enhanced fatigue life and fracture toughness. These improvements are essential for aerospace applications where repeated stress cycles, vibration, and high-temperature exposure demand absolute reliability.

Medical and Healthcare Devices

HIP is critical for medical applications such as orthopedic implants and surgical instruments. Implants produced via Titanium 3D Printing, especially from Ti-6Al-4V ELI, must be free from internal defects to ensure biocompatibility and long-term mechanical integrity. HIP removes porosity that can compromise implant safety and fatigue life in load-bearing applications like hip and spinal implants.

Energy and Power Generation

HIP is vital for components exposed to high pressure and temperature in energy systems, such as gas turbines, steam valves, and nuclear reactors. Parts manufactured using superalloys or carbon steel benefit from HIP by achieving leak-proof density and crack-free internal structures. This ensures compliance with ASME Boiler and Pressure Vessel Code requirements.

Automotive and Motorsports

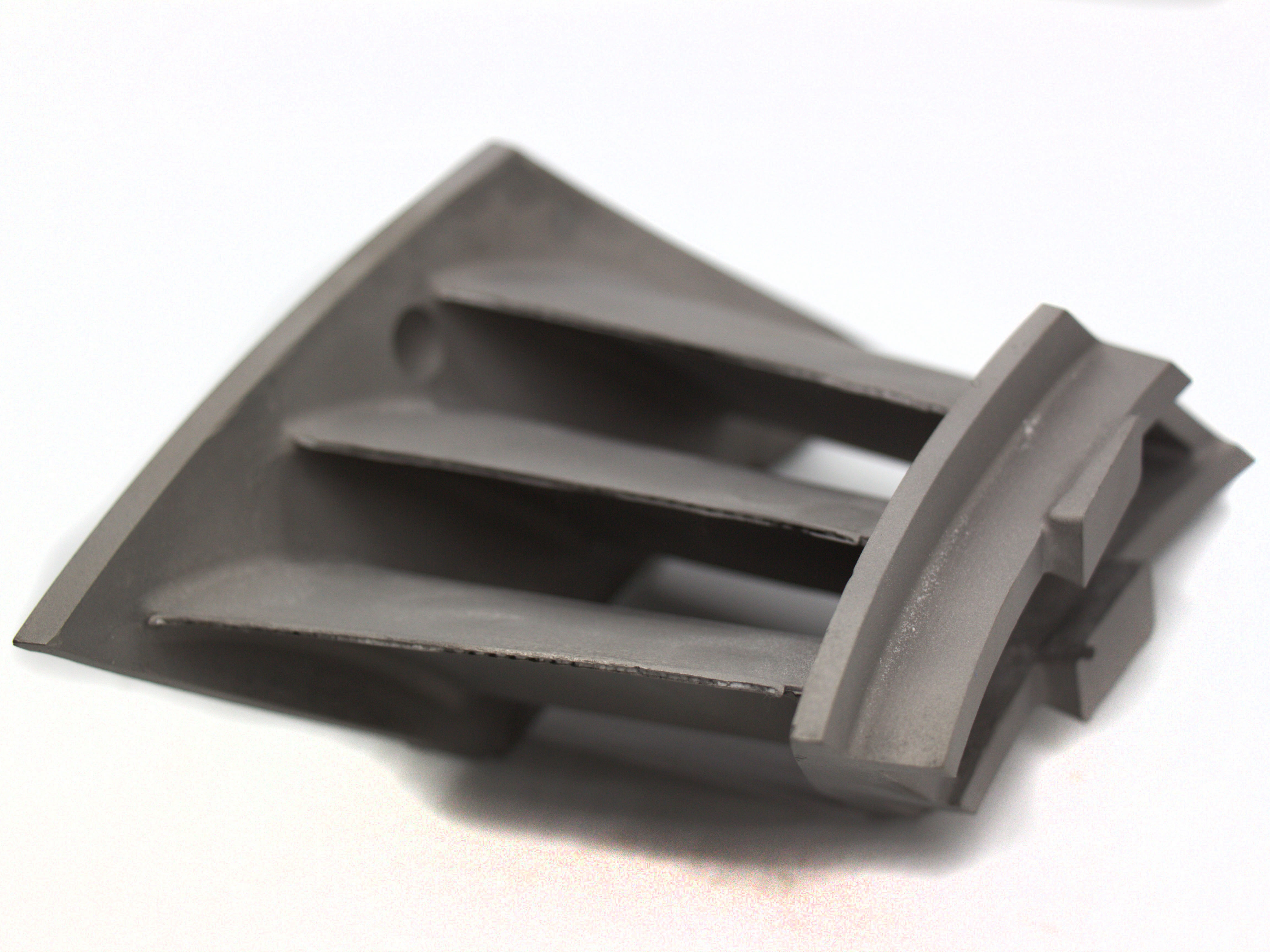

In high-performance automotive and motorsport applications, HIP processing strengthens tool steel, titanium, and stainless steel components for critical systems like turbocharger housings, gears, and brake systems. These components must endure high RPMs and repeated mechanical shocks, making HIP essential to reduce failure risk during operation.

Industrial Tooling and Dies

HIP is commonly used in tool steel molds, dies, and inserts where structural defects could lead to premature wear or failure. Eliminating internal voids enhances the tool's resistance to fatigue and thermal cycling, especially in injection molding, die casting, or stamping operations.

Recommended Services for Structural Integrity-Critical Applications

Neway offers advanced manufacturing and HIP services tailored for industries where part failure is not an option:

Industry-Specific 3D Printing:

Titanium 3D Printing: For aerospace brackets and biocompatible implants.

Superalloy 3D Printing: For turbine blades and exhaust parts.

Carbon Steel 3D Printing: For high-load structural and tooling components.

Critical Post-Processing Treatments:

Hot Isostatic Pressing (HIP): Achieves full-density and crack-free performance in metal and ceramic components.

Heat Treatment: Adjusts microstructure and hardness based on specific service conditions.

Finishing Services for Compliance and Functionality:

CNC Machining: Provides dimensional accuracy post-HIP.

Polishing: Enhances surface finish for medical and dynamic mechanical parts.