What industries benefit from combining 3D printing and EDM?

Industries That Benefit from Combining 3D Printing and EDM

Aerospace Industry

Combining 3D printing and EDM machining enables the aerospace sector to produce components with high geometric complexity and extreme dimensional precision. Critical parts such as turbine blades, injector nozzles, and heat exchangers made from Inconel 718, Hastelloy X, and Ti-6Al-4V are often 3D printed to near-net shape, then finished with EDM to meet tight tolerance (±0.002 mm) and Ra ≤ 0.2 µm surface finish requirements. EDM also enables internal channel polishing for cooling structures, which cannot be accessed by traditional tools.

Medical Industry

The medical sector benefits significantly from the hybrid use of 3D printing and EDM for producing high-precision implants and instruments. Custom bone implants, spinal cages, and surgical cutters made from Ti-6Al-4V ELI (Grade 23) or SUS316L are often additively manufactured, then refined using EDM to ensure burr-free edges, tight tolerances, and mirror-smooth surfaces suitable for biological interfaces.

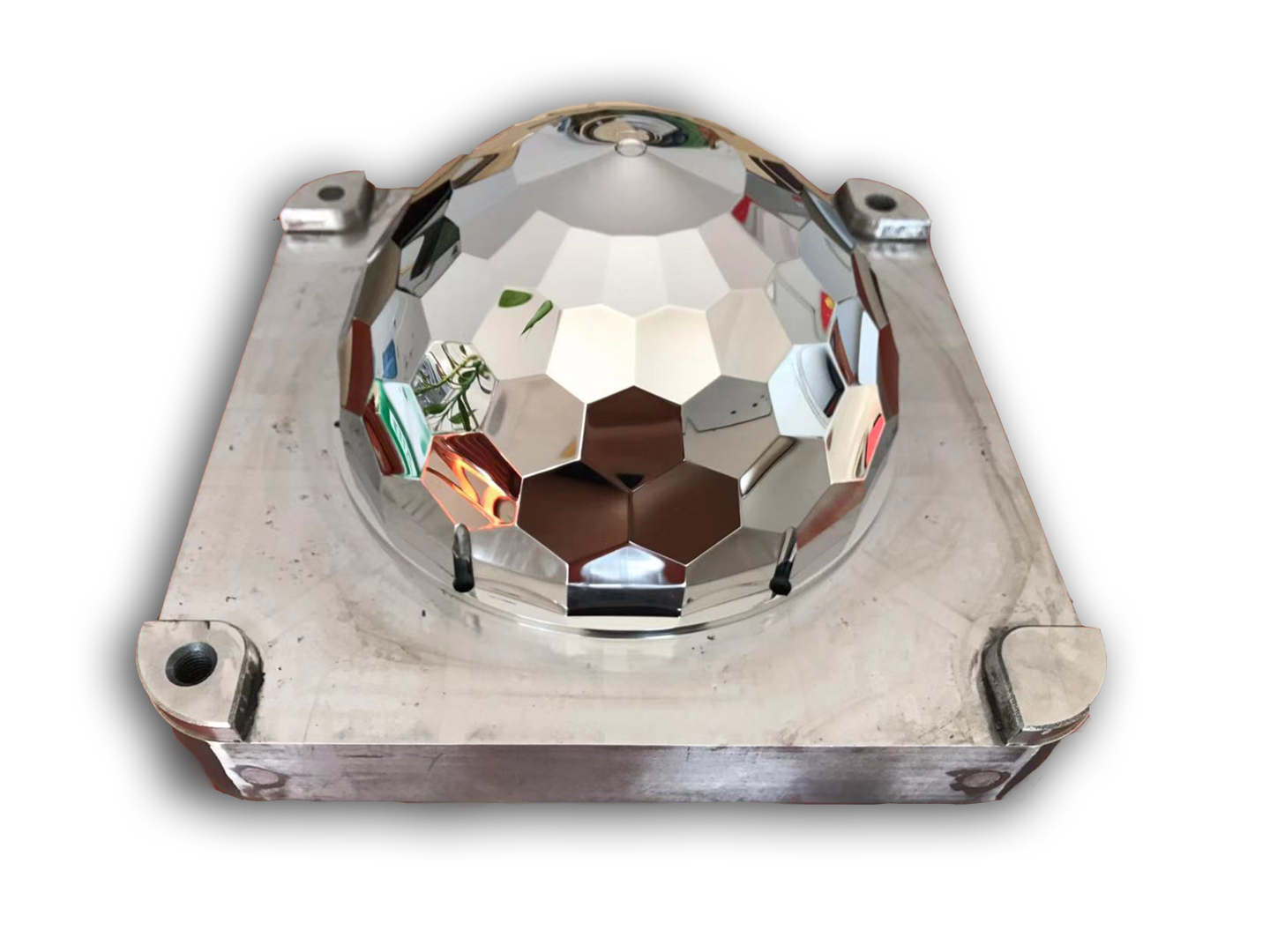

Tooling and Mold Manufacturing

In mold and die making, 3D printing provides conformal cooling or lightweighting, while EDM is used to finish hard inserts or cavity geometries with high precision. Tool steels such as Tool Steel 1.2709 and Tool Steel H13 are printed into complex core and cavity structures, then EDM-processed to ensure dimensional conformity and flawless surface finishes, improving mold performance and lifespan.

Energy and Power

In the energy sector, components like micro-channel heat exchangers, flow restrictors, and high-temperature structural elements benefit from the ability to 3D print geometrically complex designs in alloys like Haynes 230, followed by EDM to fine-tune internal features, sealing faces, and joining interfaces.

Consumer Electronics

Micro-EDM is used in conjunction with 3D printing to manufacture precision tooling for connector housings, microfluidic devices, and custom thermal solutions. Materials like Copper C101 and CuCr1Zr are used in the production of high-conductivity components with internal geometries only accessible through additive processes and EDM finishing.

Recommended Services for Industry Applications

To support cross-industry adoption of hybrid manufacturing workflows, Neway 3DP offers:

3D Printing Services For producing near-net-shape geometries using metals, ceramics, and polymers.

EDM Machining For micron-level finishing and internal geometry refinement.

Post-Processing Services Including heat treatment, polishing, and coating to meet functional and regulatory specifications.

This hybrid approach ensures performance, precision, and repeatability across demanding engineering applications.