What are the advantages of using EDM on 3D printed parts made from hard materials?

Advantages of Using EDM on 3D Printed Parts Made from Hard Materials

Non-Contact Machining Without Mechanical Stress

Electrical Discharge Machining (EDM) removes material through electrical discharges rather than physical contact. This is especially beneficial for hard, brittle, or stress-sensitive alloys such as Inconel 718, Tool Steel H13, and Ti-6Al-4V (Grade 5). Unlike traditional cutting methods, EDM eliminates the risk of tool deflection, mechanical deformation, or residual stresses—preserving dimensional stability and integrity in complex 3D printed parts.

Superior Surface Finish on Hard Alloys

EDM can achieve surface roughness values below Ra 0.2 µm on ultra-hard materials. This level of finish is difficult to reach with conventional machining due to tool wear and vibration. EDM is particularly effective at refining rough 3D printed surfaces from SLM or DMLS, especially in heat-resistant materials like Hastelloy X or Stellite 6B.

Precision on Complex and Internal Features

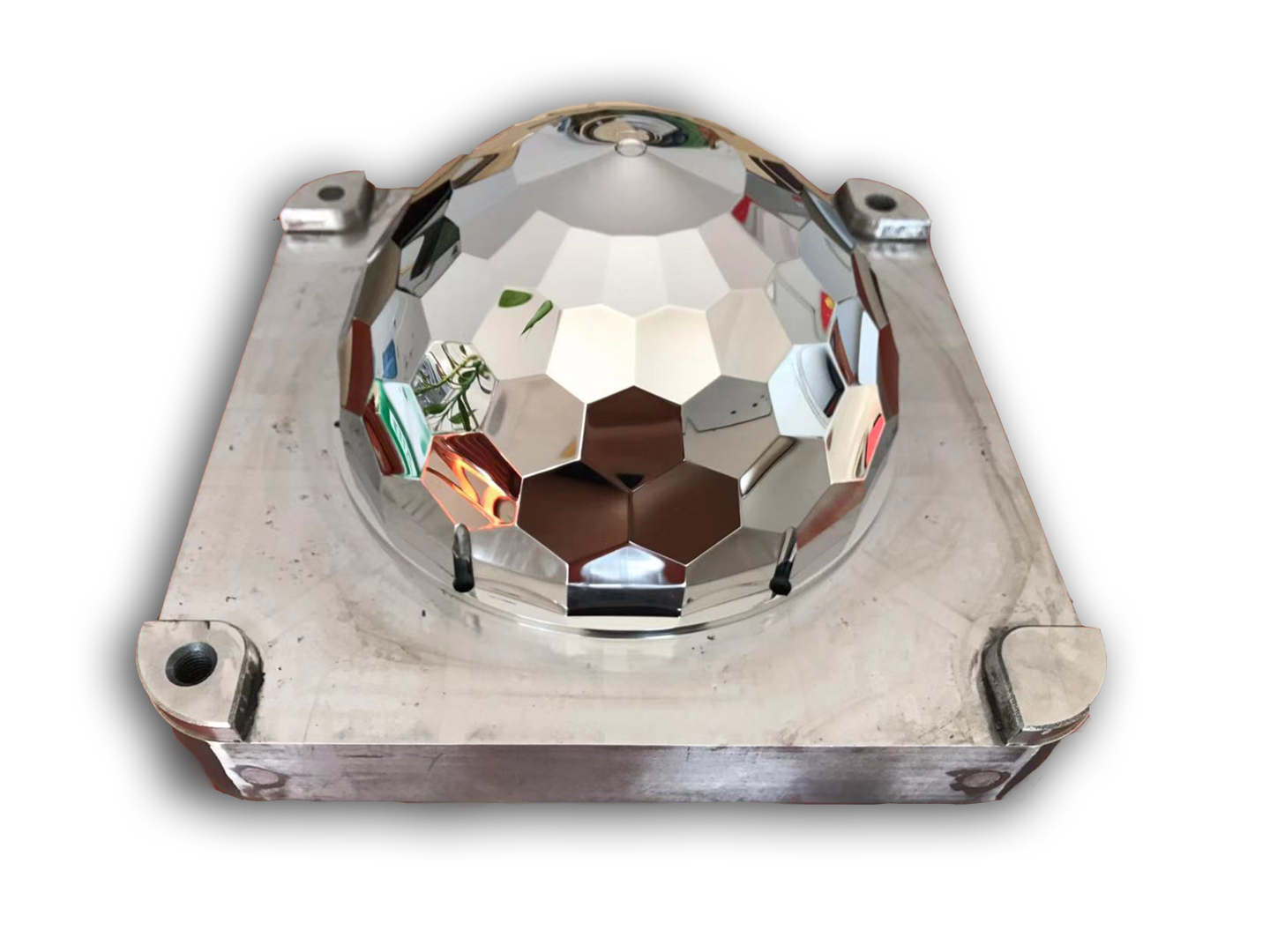

EDM is capable of machining intricate geometries and internal cavities that are difficult or impossible to access using traditional tools. Deep channels, sharp corners, micro-holes, and tight radii in 3D printed hard metal parts can be processed with sub-±0.005 mm accuracy. This is critical for turbine blades, injection molds, and surgical implants requiring fine tolerances and structural consistency.

Compatibility with High-Temperature and Wear-Resistant Alloys

Hard materials like Tool Steel D2, Haynes 230, and Ti-6Al-2Sn-4Zr-2Mo are challenging to machine due to their strength and thermal resistance. EDM handles these materials efficiently without compromising tool life or inducing surface microcracks, enabling precise finishing for high-performance components.

Common Applications in Hard-Material EDM

Aerospace turbine blades made from Inconel 625

Medical implants in Ti-6Al-4V ELI requiring burr-free fine features

Precision die inserts in Tool Steel 1.2709

Recommended Services for Hard-Material Finishing

To maximize performance and dimensional accuracy in hard metal 3D printed parts, we recommend:

EDM Machining For high-precision, stress-free material removal on hardened and heat-resistant alloys.

Heat Treatment Post-machining stabilization of tool steels and superalloys for long-term durability.

Electropolishing For enhanced corrosion resistance and finish quality in medical and aerospace-grade materials.

Neway 3DP delivers optimized workflows for machining hard 3D printed metals, from build to final finish.