Are additional treatments needed for conductivity and durability in printed copper parts?

Are Additional Treatments Needed for Conductivity and Durability in Printed Copper Parts?

Importance of Post-Processing in Copper Additive Manufacturing

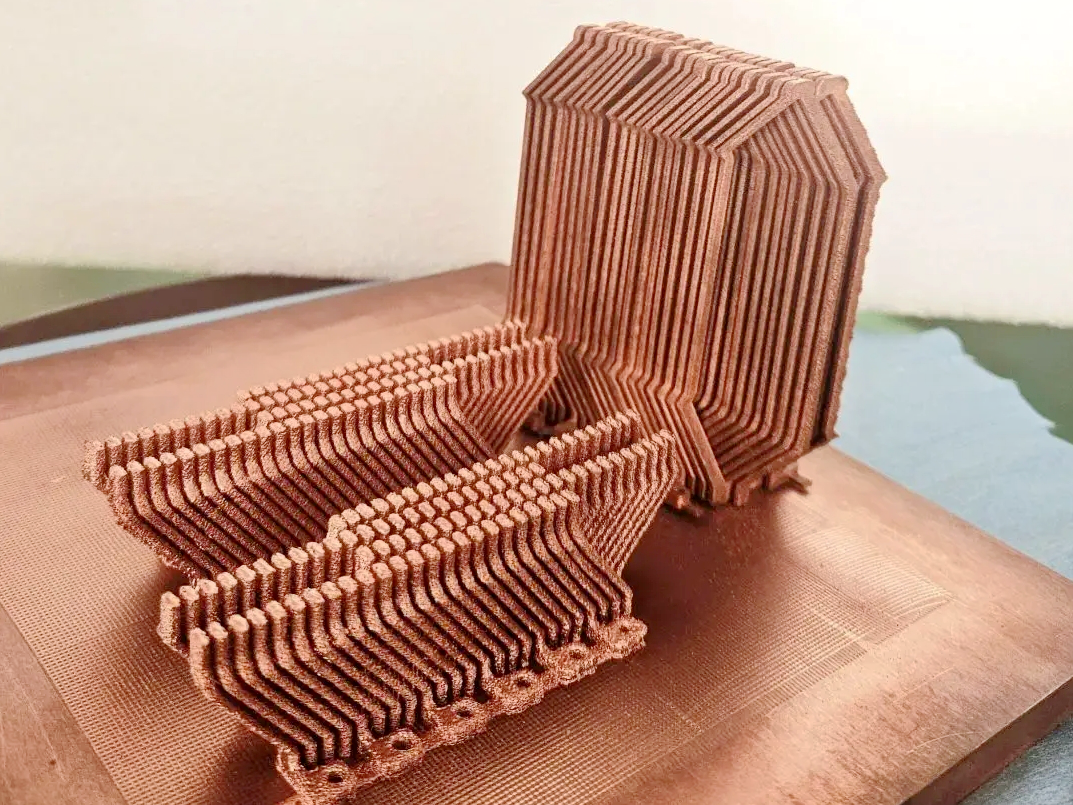

Yes, additional treatments are essential to enhance conductivity, density, and mechanical durability in 3D printed copper components. While additive manufacturing allows complex geometries with near-net-shape efficiency, untreated parts often exhibit porosity, surface oxidation, and microstructural inconsistencies that degrade performance, especially for applications in electronics, power systems, and aerospace.

Treatments to Enhance Electrical and Thermal Conductivity

Hot Isostatic Pressing (HIP)

HIP is critical for reducing internal porosity to below 1%, which significantly improves both electrical and thermal conductivity. For example, Copper C101 and C110 parts that initially demonstrate 80–85% IACS conductivity can reach over 95% IACS post-HIP, making them suitable for high-efficiency electrical and RF applications.

Heat Treatment and Annealing

Heat treatment improves grain structure and relieves internal stresses from the printing process. In the annealed condition, copper parts demonstrate higher ductility and more consistent conductivity, particularly beneficial for thin-walled or micro-feature components.

Electropolishing

Electropolishing is applied to enhance surface quality and reduce contact resistance. It achieves surface roughness as low as Ra < 1 µm, essential for precision interfaces in electrical connectors, EMI shielding, and thermal interfaces.

Durability-Focused Surface Treatments

Coatings and Surface Hardening

To improve wear resistance and environmental durability, surface treatments such as nickel electroplating or thermal barrier coatings can be applied to printed copper parts. These coatings are especially useful for components exposed to oxidation or cyclic thermal loading in industrial or aerospace environments.

CNC Finishing and Surface Machining

CNC machining can be used to refine critical surfaces and mating interfaces where precision tolerances or surface flatness are required. This also improves mechanical performance and reliability in functional assemblies.

Recommended Copper Post-Treatment Services from Neway

Conductivity Optimization Services: Achieve superior electrical and thermal performance through HIP, annealing, and electropolishing on printed copper materials like C101 and C110.

Surface Enhancement and Protection: Apply advanced surface treatments such as passivation, nickel plating, or thermal coatings for improved corrosion resistance and wear life.

Precision Finishing Services: Use CNC machining and finishing techniques to ensure dimensional accuracy, flatness, and optimal part integration in critical electronic or mechanical assemblies.