Yttria-stabilized Zirconia (YSZ)

Yttria-stabilized Zirconia (YSZ) is a partially stabilized zirconia ceramic known for its outstanding fracture toughness, ionic conductivity, and thermal shock resistance. Stabilized with 3–8 mol% yttria (Y₂O₃), YSZ offers a balance of mechanical strength and chemical durability under extreme conditions.

With ceramic 3D printing, YSZ can be shaped into custom components used in medical, energy, and aerospace applications requiring insulation, toughness, or precision under high temperatures.

YSZ Similar Grades Table

Country/Region | Standard | Grade or Designation |

|---|---|---|

USA | ASTM | ASTM F1873, F2346 |

ISO | International | ISO 13356 (medical grade) |

China | GB | GB/T 24368 |

Germany | DIN | 51084 |

Japan | JIS | JIS R1635 |

YSZ Comprehensive Properties Table

Category | Property | Value |

|---|---|---|

Physical Properties | Density | 5.9–6.1 g/cm³ |

Thermal Conductivity (25°C) | 2.0–2.5 W/(m·K) | |

Thermal Expansion (20–1000°C) | 10.5 µm/(m·K) | |

Ionic Conductivity (1000°C) | 0.1 S/cm | |

Chemical Composition | ZrO₂ | ≥90% |

Y₂O₃ | 3–8 mol% | |

Impurities | <0.1% | |

Mechanical Properties | Flexural Strength | 900–1200 MPa |

Fracture Toughness (K₁C) | 7–10 MPa·m½ | |

Hardness | 1200 HV | |

Young’s Modulus | 200 GPa |

3D Printing Technology of YSZ

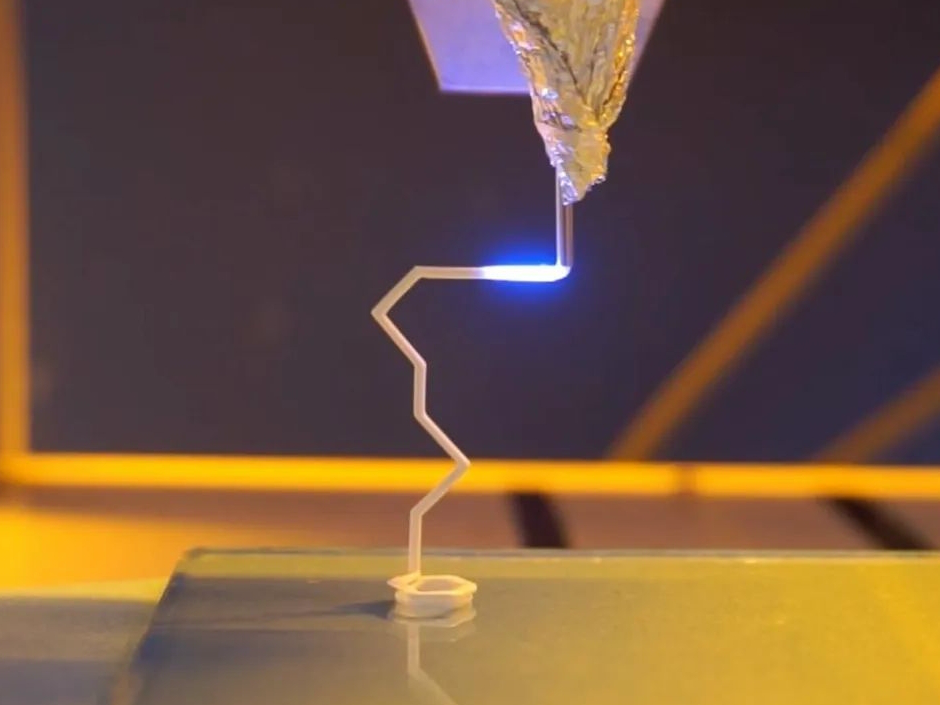

YSZ is compatible with Vat Photopolymerization (SLA, DLP), Binder Jetting, and Material Extrusion (Robocasting). These techniques allow precise shaping and control of internal structures for high-performance ceramic parts.

Applicable Process Table

Technology | Precision | Density Achievable | Application Suitability |

|---|---|---|---|

DLP/SLA | ±0.05–0.1 mm | >98% | Dental, Fuel Cells, Microparts |

Binder Jetting | ±0.1–0.3 mm | ~95% | Insulators, Tubes, Housings |

Robocasting | ±0.1–0.2 mm | ~90–94% | Electrolytes, Structural Parts |

YSZ 3D Printing Process Selection Principles

For high-resolution parts such as dental frameworks or micro-actuator components, Vat Photopolymerization offers unmatched accuracy (±0.05 mm) and >98% density after sintering.

Binder Jetting supports medium-resolution parts with internal channels or larger geometries, offering fast print speeds and post-sintered strength for general engineering use.

Material Extrusion is ideal for porous or bulk ceramic geometries where surface finish is less critical but mechanical function is essential.

YSZ 3D Printing Key Challenges and Solutions

YSZ is susceptible to warping and microcracking during drying and sintering. Using controlled drying cycles and optimized shrinkage models minimizes shape distortion.

Low green part strength can limit handling pre-sintering. Enhancing binder systems and controlled debinding prevents breakage and ensures dimensional accuracy.

Oxygen-sensitive grain boundary impurities may degrade ionic conductivity. Sintering in clean or inert atmospheres (e.g., vacuum or argon) ensures chemical stability.

High sintering temperatures (1400–1500°C) can induce exaggerated grain growth. Using nanoscale powders and step-sintering techniques enhances densification while preserving mechanical properties.

Typical Post-Processing for YSZ 3D Printed Parts

Sintering at 1400–1500°C increases density and mechanical properties of YSZ for structural and electrolyte applications. Polishing improves surface finish of dental crowns and components requiring optical clarity and tight tolerances. Electropolishing is used for fine internal passages and biomedical ceramic components with complex shapes. Coating with bio-inert or thermal barrier films extends service life in implants and energy system applications.

Industry Application Scenarios and Cases

Yttria-stabilized Zirconia is used in:

Medical and Dental: Crowns, bridges, root posts, and prosthetic implants for their toughness and biocompatibility.

Energy and Power: Solid oxide fuel cell (SOFC) electrolytes and thermal barrier coatings.

Aerospace and Defense: Insulators, heat shields, and wear-resistant parts requiring low thermal conductivity and high fracture toughness.

A notable case involved 3D printed YSZ solid oxide fuel cell membranes via DLP, achieving over 99% theoretical density and reducing manufacturing cost by 35% compared to CNC machining.

FAQs

What are the benefits of using YSZ in 3D printed dental applications?

Which 3D printing technologies are best suited for zirconia ceramic parts?

How is YSZ different from traditional alumina ceramics?

What are the main challenges in sintering YSZ components?

Can YSZ 3D printed parts replace machined ceramics in energy systems?