Boron Carbide (B4C)

Boron Carbide (B₄C) is one of the hardest known ceramics, with exceptional hardness, low density, and excellent neutron absorption properties. It is widely used in defense, nuclear, and abrasive applications requiring maximum wear and ballistic performance.

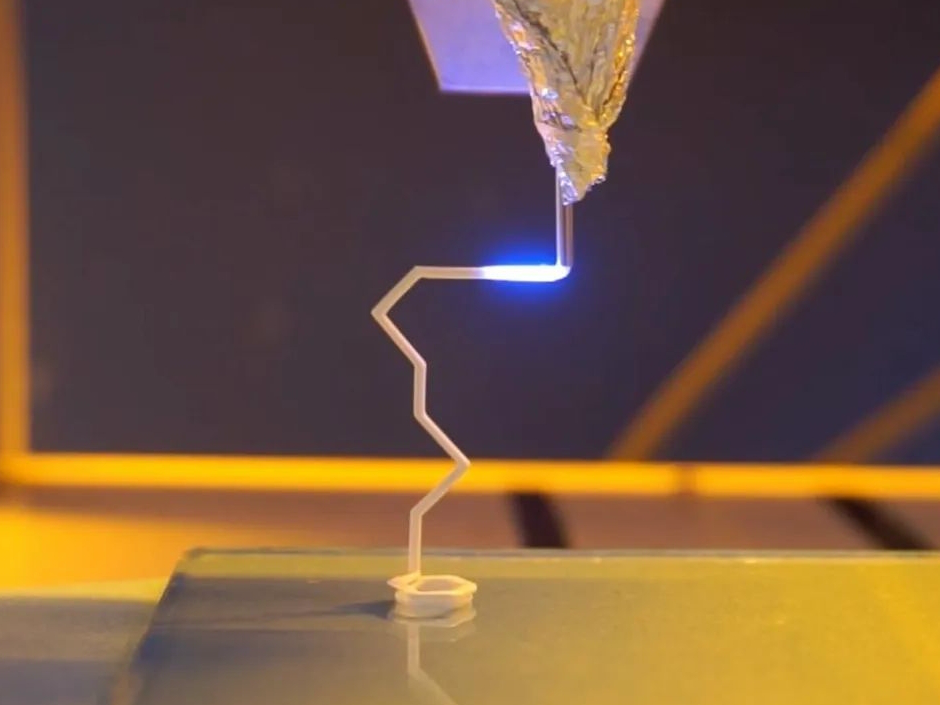

Using advanced ceramic 3D printing, B₄C enables production of complex geometries such as lightweight armor panels, neutron shielding blocks, and wear-resistant nozzles. Additive manufacturing enables weight reduction, rapid prototyping, and precise customization.

Boron Carbide Similar Grades Table

Grade Type | Purity (%) | Typical Applications |

|---|---|---|

Technical Grade | 95–97 | Abrasive nozzles, blast linings |

Nuclear Grade | ≥99.0 | Neutron shields, reactor control rods |

Armor Grade | ≥99.5 | Ballistic plates, personal body armor |

Boron Carbide Comprehensive Properties Table

Category | Property | Value |

|---|---|---|

Physical Properties | Density | 2.50–2.52 g/cm³ |

Melting Point | ~2450°C | |

Thermal Conductivity (25°C) | 30–45 W/(m·K) | |

Electrical Resistivity (25°C) | >10⁶ Ω·cm | |

Thermal Expansion (25–1000°C) | 5.0 µm/(m·K) | |

Mechanical Properties | Hardness (Vickers) | 2700–3200 HV |

Flexural Strength | 300–450 MPa | |

Compressive Strength | ≥3000 MPa | |

Elastic Modulus | 440–470 GPa | |

Fracture Toughness (K₁C) | 2–3 MPa·m½ |

3D Printing Technology of Boron Carbide

B₄C is typically 3D printed using Binder Jetting due to its high melting point and sintering complexity. It requires debinding and sintering or infiltration post-processing to achieve near-full density and structural integrity.

Applicable Process Table

Technology | Precision | Surface Quality | Mechanical Properties | Application Suitability |

|---|---|---|---|---|

Binder Jetting | ±0.1–0.3 mm | Good | Very Good (after HIP) | Armor Panels, Neutron Absorbers |

Hybrid Infiltration | ±0.1–0.3 mm | Good | Excellent | Tool Inserts, Ballistic Components |

Boron Carbide 3D Printing Process Selection Principles

Binder Jetting is ideal for large-format or batch production of lightweight B₄C components like ballistic tiles, allowing cost-effective forming and sintering of hard-to-machine ceramics.

For parts requiring extreme hardness and structural performance, hybrid processing involving infiltration (e.g., Si infiltration) after printing improves strength, making it suitable for armor and reactor applications.

Boron Carbide 3D Printing Key Challenges and Solutions

B₄C has low sinterability due to covalent bonding. Densification requires sintering aids, pressure-assisted sintering, or infiltration techniques to reach ≥95% theoretical density.

Shrinkage (~20–25%) is significant; precise CAD compensation and controlled sintering cycles are essential to ensure geometric accuracy.

Fracture toughness is inherently low. Using HIP post-processing and grain refinement techniques enhances strength while preserving ultra-hard surfaces.

Fine surface features may suffer from edge chipping. Post-sinter diamond polishing achieves Ra < 1 µm and eliminates surface micro-cracks.

Industry Application Scenarios and Cases

Boron carbide 3D printing is used in:

Defense: Lightweight armor plates, blast shields, body armor inserts.

Nuclear Energy: Neutron shielding elements, reactor control parts.

Industrial: Abrasive nozzles, wear rings, and cutting tool blanks.

Aerospace: Lightweight impact-resistant panels and radiation protection.

In a military program, 3D printed B₄C armor tiles achieved 35% weight reduction over alumina while maintaining equivalent ballistic performance, enabling higher mobility and payload capacity.

FAQs

Why is Boron Carbide preferred for lightweight armor applications?

What 3D printing technologies are suitable for B₄C ceramic parts?

How is post-processing handled for 3D printed B₄C components?

What are the key challenges in sintering Boron Carbide?

Which industries benefit most from 3D printed B₄C components?