Aluminum Nitride (AlN)

Aluminum Nitride (AlN) is a high-performance ceramic offering excellent thermal conductivity, high electrical insulation, and low thermal expansion. It is ideal for microelectronics, power electronics, and thermal management systems operating in compact, high-heat environments.

With advanced ceramic 3D printing, AlN enables rapid fabrication of heat sinks, substrates, and insulating fixtures with complex geometries and internal channels. Additive manufacturing provides superior design flexibility, reduced tooling costs, and excellent thermal reliability for electronics packaging.

Aluminum Nitride Similar Grades Table

Grade Type | Purity (%) | Typical Applications |

|---|---|---|

Technical AlN | 95–98 | Power module insulation, sensor packages |

High-Purity AlN | ≥99.5 | Semiconductor tools, laser diode submounts |

Composite AlN | AlN + Y₂O₃ | High-strength thermally conductive fixtures |

Aluminum Nitride Comprehensive Properties Table

Category | Property | Value |

|---|---|---|

Physical Properties | Density | 3.26 g/cm³ |

Thermal Conductivity (25°C) | 140–180 W/(m·K) | |

Melting Point | ~2200°C | |

Electrical Resistivity (25°C) | >10¹³ Ω·cm | |

Thermal Expansion (25–1000°C) | 4.5 µm/(m·K) | |

Mechanical Properties | Hardness (Vickers) | 1100–1300 HV |

Flexural Strength | 300–400 MPa | |

Compressive Strength | ≥1500 MPa | |

Elastic Modulus | 310 GPa | |

Fracture Toughness (K₁C) | 3–4 MPa·m½ |

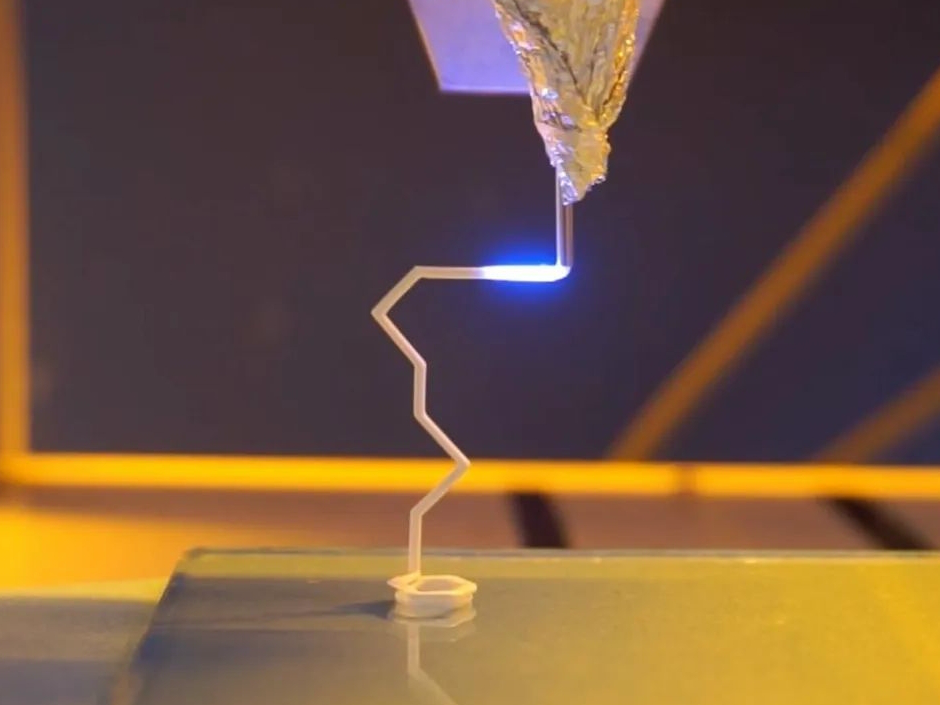

3D Printing Technology of Aluminum Nitride

AlN is typically 3D printed via Vat Photopolymerization (VPP) and Binder Jetting, followed by debinding and sintering in oxygen-free atmospheres. These processes allow for production of thermally conductive ceramic parts with fine features and complex internal structures.

Applicable Process Table

Technology | Precision | Surface Quality | Mechanical Properties | Application Suitability |

|---|---|---|---|---|

Vat Photopolymerization (VPP) | ±0.05–0.2 mm | Excellent | Very Good | Thermal Substrates, Sensor Fixtures |

Binder Jetting | ±0.1–0.3 mm | Good | Moderate | Heat Spreaders, Power Housings |

Aluminum Nitride 3D Printing Process Selection Principles

VPP is ideal for high-precision AlN applications such as LED submounts, microchannel coolers, and ceramic PCBs where surface quality and fine geometry are critical.

Binder Jetting suits larger heat-dissipating structures like power electronics modules or packaging parts that require thermal performance over form complexity.

Aluminum Nitride 3D Printing Key Challenges and Solutions

AlN is sensitive to oxidation and hydrolysis. Printing and post-processing must occur in controlled atmospheres (N₂ or inert gas, RH < 30%) to prevent surface degradation.

Shrinkage (15–22%) during sintering requires precise CAD compensation. Optimized debinding and sintering schedules ensure final part integrity and thermal conductivity.

Porosity impacts thermal performance. Using high-solids-loading slurries and tailored sintering profiles enables densities above 98%, with conductivity >160 W/(m·K) achievable.

Surface finishing is critical in electronic interfaces. Polishing and CNC machining can reduce Ra to <1.0 µm for optimal thermal contact and component assembly.

Industry Application Scenarios and Cases

Aluminum Nitride 3D printing is used in:

Power Electronics: IGBT baseplates, MOSFET insulation, and power converter packaging.

Semiconductor & Optoelectronics: Laser diode mounts, LED heat sinks, and wafer-level thermal solutions.

Automotive & Aerospace: Thermal isolation mounts, ignition modules, and RF shielding devices.

In a power module project, VPP-printed AlN substrates delivered 160 W/(m·K) conductivity and <±0.1 mm dimensional tolerance, enabling 25% reduction in package size and improved thermal management over alumina-based designs.

FAQs

Why is Aluminum Nitride preferred over Alumina for thermal applications?

What is the maximum achievable thermal conductivity in 3D printed AlN?

Which industries benefit most from AlN ceramic 3D printing?

What sintering conditions are required for Aluminum Nitride?

How does VPP compare to Binder Jetting for AlN component fabrication?