Tool Steel H13

H13 3D Printing Materials Introduction

Tool Steel H13 is a chromium-based alloy renowned for its excellent toughness, wear resistance, and resistance to thermal fatigue. It is frequently used in applications involving high heat and high stress, such as die casting, forging, and plastic molding tools.

Through H13 3D printing, high-performance tooling components can be rapidly produced with complex shapes and precise tolerances, enhancing the tool's ability to withstand thermal and mechanical stresses in challenging environments.

H13 Similar Grades Table

Country/Region | Standard | Grade or Designation | Synonyms |

|---|---|---|---|

USA | ASTM | H13 | AISI H13, DIN 1.2344 |

UNS | Unified | T20813 | - |

ISO | International | 1.2344 | - |

China | GB/T | 4Cr5MoSiV1 | Cr5MoSiV1 |

Germany | DIN/W.Nr. | 1.2344 | - |

H13 Comprehensive Properties Table

Category | Property | Value |

|---|---|---|

Physical Properties | Density | 7.80 g/cm³ |

Melting Point | 1380°C | |

Thermal Conductivity (100°C) | 30.0 W/(m·K) | |

Electrical Resistivity | 60 µΩ·cm | |

Chemical Composition (%) | Carbon (C) | 0.32–0.45 |

Chromium (Cr) | 4.75–5.50 | |

Molybdenum (Mo) | 1.10–1.75 | |

Vanadium (V) | 0.80–1.20 | |

Silicon (Si) | 1.00–1.50 | |

Iron (Fe) | Balance | |

Mechanical Properties | Tensile Strength | 1300 MPa |

Yield Strength (0.2%) | 950 MPa | |

Hardness (HRC) | 48–53 HRC | |

Modulus of Elasticity | 200 GPa |

3D Printing Technology of H13

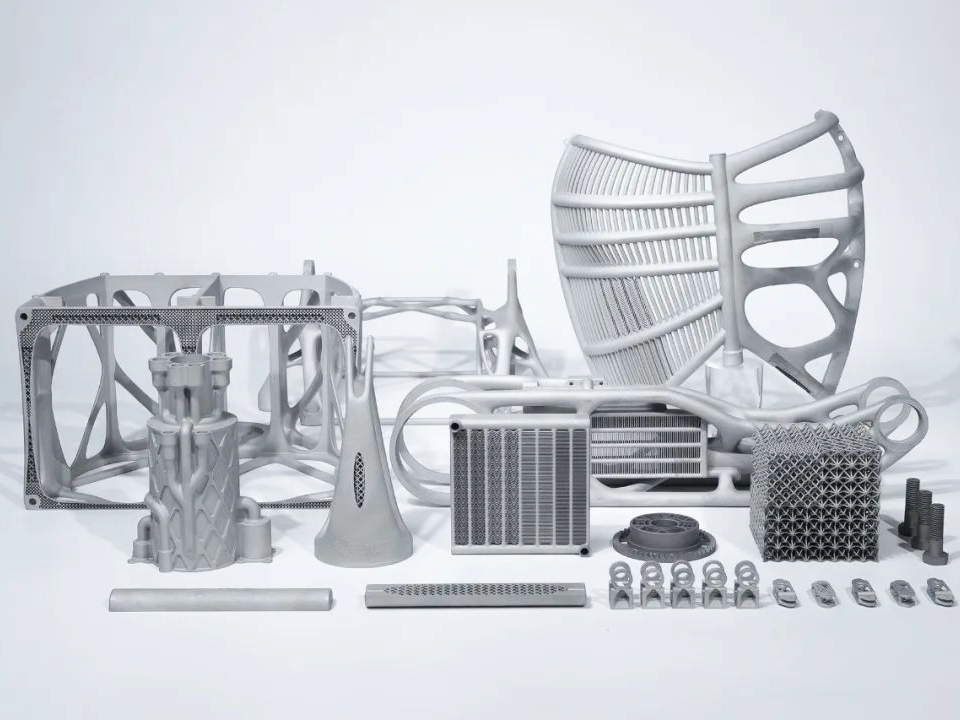

Tool Steel H13 can be 3D printed with technologies like Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), and Electron Beam Melting (EBM). These processes help produce complex geometries with high dimensional accuracy and excellent thermal properties, ideal for tooling used in high-stress, high-temperature environments.

Applicable Process Table

Technology | Precision | Surface Quality | Mechanical Properties | Application Suitability |

|---|---|---|---|---|

SLM | ±0.05–0.1 mm | Excellent | High Temperature | Molds, Dies, Forging Tools |

DMLS | ±0.05–0.1 mm | Very Good | Excellent | Tooling, High-Precision Molds |

EBM | ±0.1–0.3 mm | Good | High-Temp Resilience | Heavy-Duty Forging and Casting |

H13 3D Printing Process Selection Principles

Selective Laser Melting (SLM): SLM delivers >99.5% part density using 30 µm layers and 800–1000 mm/s scan speed, ideal for high-precision molds and inserts with complex conformal cooling designs.

Direct Metal Laser Sintering (DMLS): DMLS enables production of dense, functional tools with fine details and internal features, using 300–350 W laser power and maintaining dimensional accuracy within ±0.05 mm.

Electron Beam Melting (EBM): EBM suits large, thermally loaded parts. With preheat up to 800°C, it minimizes residual stress and is preferred for thick-walled forging tools and hot work components.

H13 3D Printing Key Challenges and Solutions

Residual Stress and Distortion: H13 is prone to thermal stress and warping during printing. Stress relief annealing at 600–650°C for 2 hours improves dimensional stability and reduces crack risk.

Surface Roughness and Porosity: As-built Ra 8–12 µm may hinder ejection or fit. Electropolishing reduces roughness below Ra 1.0 µm.

Microstructure Brittleness Without Heat Treatment: If left untreated, H13 may be brittle. Quenching at 1020°C and tempering at 550°C achieves HRC 48–53 and good toughness.

Corrosion Resistance in Harsh Environments: H13 offers moderate corrosion resistance. Passivation removes surface iron and improves oxide layer protection.

Typical Post-Processing for H13 3D Printed Parts

Quenching and Tempering: Heat treatment at 1020°C followed by tempering at 550°C improves toughness, wear resistance, and raises hardness to HRC 48–53 for high-temperature tooling use.

CNC Machining: CNC machining is used to refine critical dimensions, improve fits, and achieve ±0.02 mm tolerances for tight clearances in die cavities and core details.

Electropolishing: Electropolishing reduces Ra below 1.0 µm, improving surface release in molding tools and minimizing galling in high-friction die components.

Passivation: Passivation eliminates free iron from surfaces, enhancing corrosion resistance of hot work molds used in humid or chemically reactive production environments.

Industry Application Scenarios and Cases

H13 is widely used in:

Die Casting: Molds and inserts for high-pressure die casting in automotive and aerospace industries.

Forging Tools: Dies and molds for hot working of metals at elevated temperatures.

Plastic Molding: Injection molds and extrusion dies in the plastics industry, providing high strength and thermal resistance. A case study from the automotive industry demonstrated how H13 3D printed molds increased productivity by 40%, reducing cycle times and tool replacement costs.

FAQs

What is the maximum operating temperature for H13 3D printed tools?

How does H13 compare to other hot work tool steels in terms of thermal fatigue resistance?

What are the best post-processing techniques for H13 3D printed parts?

How can H13 3D printing improve the efficiency of mold production?

Is H13 3D printing suitable for high-pressure die casting molds?