Tool Steel MS1

MS1 3D Printing Materials Introduction

Tool Steel MS1 is a high-carbon, high-alloy steel specifically designed for use in tooling applications. It combines excellent wear resistance and hardness, making it suitable for manufacturing die-casting molds, extrusion dies, and other industrial tooling components that operate under high-stress conditions.

With MS1 3D printing, manufacturers can produce tools with intricate geometries and enhanced precision, offering performance that is hard to achieve through traditional manufacturing methods.

MS1 Similar Grades Table

Country/Region | Standard | Grade or Designation | Synonyms |

|---|---|---|---|

USA | ASTM | MS1 | AISI MS1, DIN 1.2316 |

UNS | Unified | T20816 | - |

ISO | International | 1.2316 | - |

China | GB/T | 3Cr2Mo | Cr2Mo |

Germany | DIN/W.Nr. | 1.2316 | - |

MS1 Comprehensive Properties Table

Category | Property | Value |

|---|---|---|

Physical Properties | Density | 7.80 g/cm³ |

Melting Point | 1420°C | |

Thermal Conductivity (100°C) | 32.5 W/(m·K) | |

Electrical Resistivity | 65 µΩ·cm | |

Chemical Composition (%) | Carbon (C) | 0.35–0.45 |

Chromium (Cr) | 12.00–14.00 | |

Molybdenum (Mo) | 1.00–2.00 | |

Vanadium (V) | 0.20–0.50 | |

Iron (Fe) | Balance | |

Mechanical Properties | Tensile Strength | 1100 MPa |

Yield Strength (0.2%) | 750 MPa | |

Hardness (HRC) | 52–56 HRC | |

Modulus of Elasticity | 200 GPa |

3D Printing Technology of MS1

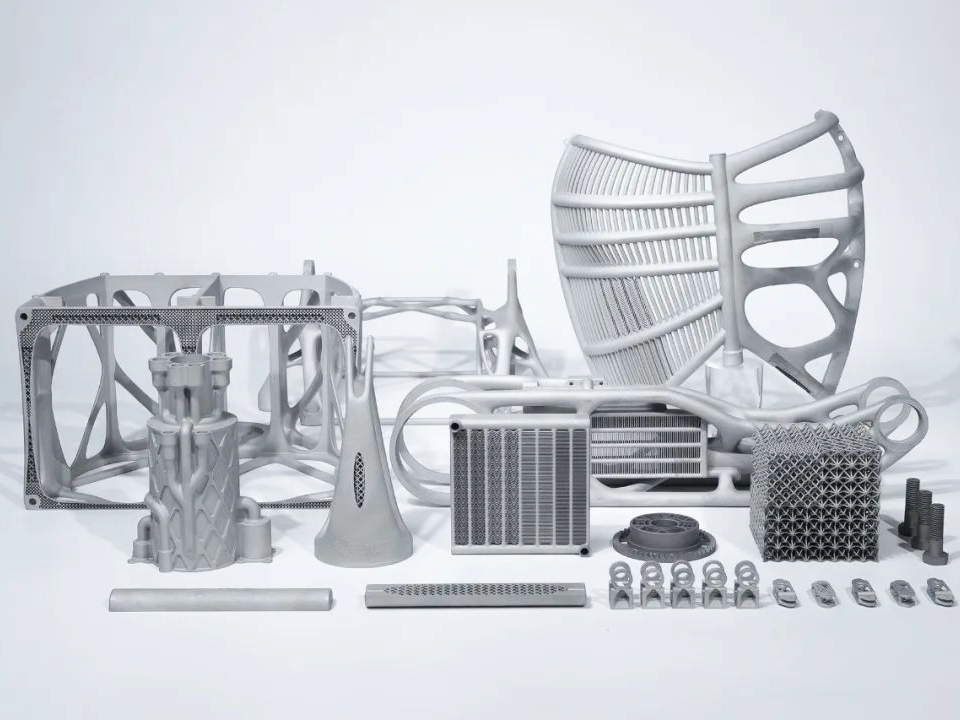

Tool Steel MS1 can be processed through various 3D printing technologies, including Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), and Electron Beam Melting (EBM). These methods ensure high part density and excellent mechanical properties, producing tooling parts with exceptional wear and thermal resistance.

Applicable Process Table

Technology | Precision | Surface Quality | Mechanical Properties | Application Suitability |

|---|---|---|---|---|

SLM | ±0.05–0.1 mm | Excellent | High Temperature | Molds, Dies, Forging Tools |

DMLS | ±0.05–0.1 mm | Very Good | Excellent | Tooling, High-Precision Molds |

EBM | ±0.1–0.3 mm | Good | High-Temp Resilience | Heavy-Duty Forging and Casting |

MS1 3D Printing Process Selection Principles

Selective Laser Melting (SLM): SLM uses a high-powered laser to melt and fuse metal powder layer by layer. This technology offers high accuracy and is ideal for complex geometries, particularly in producing tooling parts such as dies and molds.

Direct Metal Laser Sintering (DMLS): DMLS allows for excellent material properties and complex designs. It is optimal for producing intricate tooling parts with high thermal and mechanical stress resistance.

Electron Beam Melting (EBM): EBM utilizes an electron beam in a vacuum, ideal for large, dense parts. It minimizes thermal residual stresses and is suitable for creating large forging dies and high-temperature tooling.

MS1 3D Printing Key Challenges and Solutions

Residual Stress and Distortion: Hardened MS1 may exhibit high residual stress during printing. Pre-heating and post-process stress relief annealing (600–650°C) can significantly reduce warping and dimensional instability.

Surface Roughness: The surface finish of MS1 parts can have a high roughness value, which can negatively affect mold performance. Electropolishing and machining can reduce the surface roughness to Ra 1.0 µm for enhanced mold release and smoother ejection.

Porosity and Incomplete Fusion: DMLS helps avoid incomplete fusion by using fine powder and controlling the heat profile during the build. This ensures that parts have high density and low porosity, improving mechanical strength.

Corrosion Resistance: While MS1 is corrosion-resistant, further passivation treatments help to improve its resistance to rust, making it suitable for molds and tooling exposed to aggressive environments.

Typical Post-Processing for MS1 3D Printed Parts

Quenching and Tempering: Heat treatment at 1030°C followed by tempering at 540°C enhances wear resistance, raises hardness to HRC 52–56, and improves toughness for heavy-duty tooling applications.

CNC Machining: CNC machining is essential to achieve dimensional accuracy and tolerances of ±0.02 mm, especially for precise fit parts like injection molds and dies, where tight tolerances are critical.

Electropolishing: Electropolishing improves the surface quality of MS1 3D printed parts, reducing the roughness to Ra 1.0 µm, enhancing mold release properties,s and providing smoother surfaces for plastic molding.

Passivation: Passivation increases corrosion resistance by treating the surface to create a protective oxide layer, which helps extend the life of tooling exposed to harsh production environments.

Industry Application Scenarios and Cases

MS1 is widely used in:

Die Casting: Molds and inserts for high-pressure die casting in the automotive and aerospace industries.

Forging Tools: Dies and molds for hot working of metals at elevated temperatures.

Plastic Molding: Injection molds and extrusion dies in the plastics industry, providing high strength and thermal resistance. A case study from the automotive industry demonstrated how MS1 3D printed molds increased productivity by 40%, reducing cycle times and tool replacement costs.

FAQs

What are the mechanical properties of MS1 3D printed tools?

How can MS1 3D printing improve the speed and efficiency of mold production?

What post-processing steps are required for MS1 3D printed parts?

Can MS1 be used for high-pressure die casting molds?

How does MS1 compare to other tool steels like H13 or D2 for tooling applications?