¿Qué materiales se utilizan normalmente para piezas de titanio en Selective Laser Melting (SLM)?

Tabla de contenidos

What Materials Are Typically Used for Titanium Parts in Selective Laser Melting (SLM)?

Ti-6Al-4V (Grade 5)

Ti-6Al-4V ELI (Grade 23)

Ti-6Al-2Sn-4Zr-2Mo

Ti-5Al-5V-5Mo-3Cr (Ti-5553)

Ti-6.5Al-1Mo-1V-2Zr (TA15)

Customer-Oriented Solutions and Services

Español / ES

Título

¿Qué materiales se utilizan normalmente para piezas de titanio en Selective Laser Melting (SLM)?

Descripción

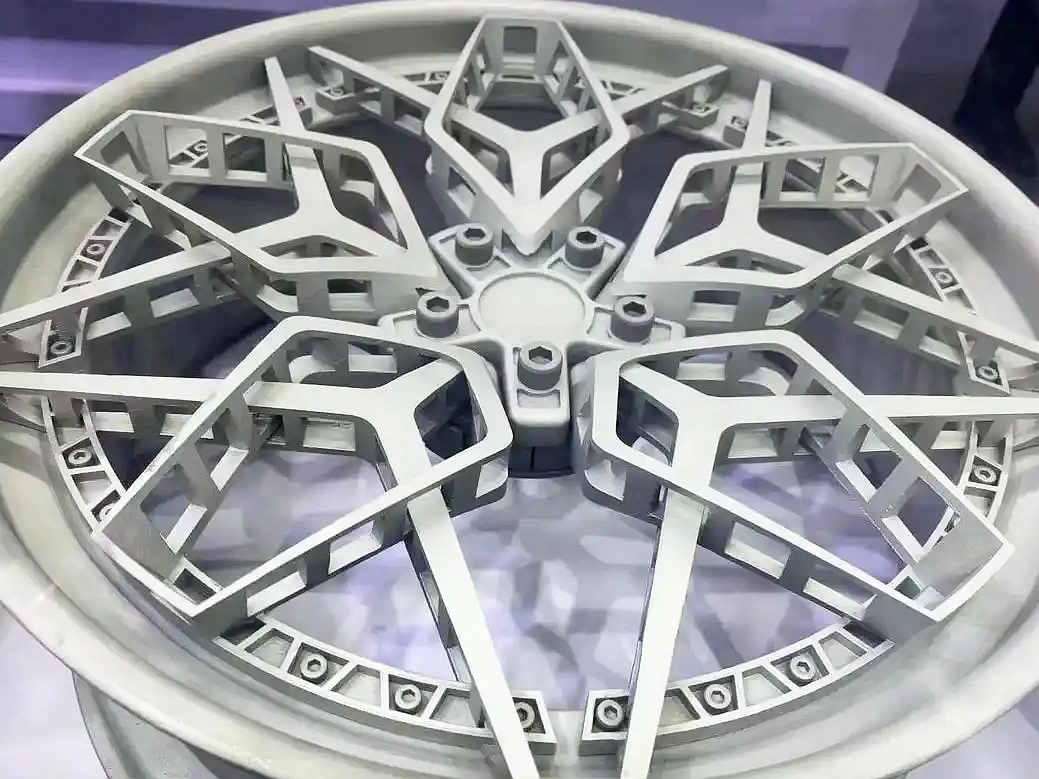

Las piezas de titanio SLM suelen fabricarse con aleaciones como Ti-6Al-4V, Ti-5553 y TA15, que ofrecen alta resistencia, durabilidad a la fatiga y rendimiento de grado aeroespacial. Explore nuestras capacidades de impresión 3D en titanio.

Palabras clave

aleaciones de titanio SLM, impresión Ti-6Al-4V, componentes aeroespaciales de titanio, impresión 3D de titanio de alta resistencia, piezas resistentes a la fatiga, fabricación aditiva Ti-5553, titanio médico, piezas de titanio personalizadas

Related Blogs

Suscríbase para recibir consejos de diseño y fabricación de expertos en su bandeja de entrada.

Compartir esta publicación: