STA (TG-DSC): Thermal Stability & Process Window for Reliable AM

Introduction: Predicting Thermal Behavior – How STA Defines Safe Process Boundaries for Reliable AM

In additive manufacturing, every successful build is essentially a precise exercise in temperature control. As materials R&D engineers at Neway, we understand that thermal stability not only affects the smooth execution of the printing process, but also directly determines the final microstructure and in-service performance of the part. However, a material’s behavior during heating is often difficult to predict, which is exactly why we introduced simultaneous thermal analysis (STA). STA acts as a precise “interpreter” of thermal behavior, synchronously measuring mass change and heat flow during heating to reveal how materials respond to thermal exposure, providing a scientific basis for optimizing process parameters.

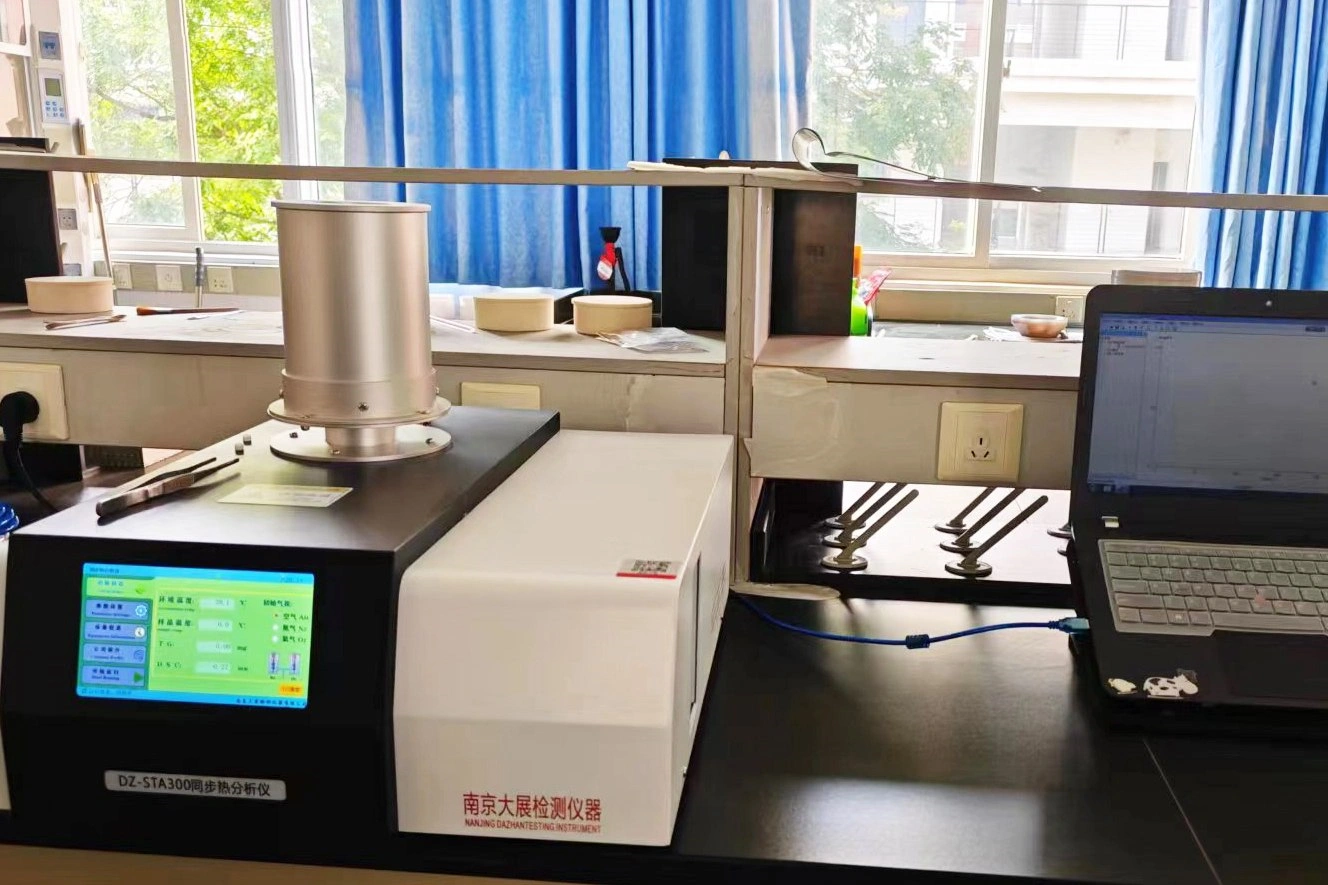

What Is Simultaneous Thermal Analysis?

TG and DSC Synergy: Dual Interpretation of Mass and Energy

The core of STA lies in combining thermogravimetric analysis (TG) and differential scanning calorimetry (DSC) within a single experimental system. The TG unit monitors mass changes under programmed temperature conditions and accurately captures processes such as decomposition, oxidation, and volatilization that involve mass variation. For example, when testing metal powders in air, the TG curve clearly indicates the exact temperature at which oxidation starts. The DSC unit simultaneously measures the heat flow difference between the sample and a reference, accurately identifying thermal transitions such as melting, crystallization, and curing. This powerful combination allows us to obtain a complete thermal behavior profile of the material in a single experiment under identical conditions.

The Unique Value of STA in AM Applications

In additive manufacturing, STA demonstrates unique advantages. Compared with single-mode thermal analysis, STA correlates mass change and thermal effects precisely under the same experimental conditions. This correlation is particularly valuable for understanding complex AM thermal processes—for instance, the thermal behavior of powders in powder bed fusion, or the curing behavior of resins in vat photopolymerization. Through STA, we provide integrated thermal characterization solutions tailored to different AM processes.

How Neway Uses STA to Define Thermal Stability and Process Windows for AM Materials

Evaluating Metal Powder Oxidation Behavior – Defining Safe Printing Temperatures

In metal AM, powder oxidation behavior directly impacts print quality. Using STA in air, we record TG curves of metal powders to accurately determine the onset temperature of significant oxidation for reactive alloys such as aluminum alloys. These data define key parameters for inert gas protection during printing, ensuring good metallurgical integrity throughout processing. For example, for a highly reactive aluminum alloy powder, we observed a clear mass gain beginning at 280°C, providing our process team with a clear upper boundary for safe operation.

Analyzing Polymer/Resin Curing to Optimize Printing Parameters

For polymer-based materials, STA helps us precisely define the processing window. DSC analysis enables the identification of the curing exotherm peak of photo-curable resins and the melting temperature of engineering thermoplastics, while TG reveals the onset of thermal degradation. Together, these results define the safe temperature range for printing and post-curing. For example, when developing a high-performance PEEK printing process, STA exhibited an onset of melting at around 340°C and decomposition beginning near 560°C, thereby providing a clear temperature window for our material extrusion process settings.

Binder Decomposition Kinetics to Guide Debinding Processes

In binder jetting, binder decomposition behavior directly influences debinding strategy. Using STA, we accurately determine the decomposition temperature range and rate of the binder system, a critical input for designing efficient, defect-free debinding curves. By optimizing heating rates and hold steps, we ensure smooth and complete binder removal while avoiding damage to fragile green parts.

From STA Data to Robust AM Process Windows

Defining the Sintering Window

STA helps us pinpoint suitable sintering windows. By analyzing DSC exothermic/endothermic peaks together with TG mass change, we identify the ideal temperature range where powders begin to sinter without excessive densification or distortion. This is especially important for optimizing sintering profiles for metal and ceramic AM components.

Anticipating Thermal Risks in Printing

STA enables early detection of potential thermal risks during printing. By identifying unexpected phase transitions or decomposition reactions within the intended process temperature range, we can proactively adjust process parameters and avoid build failures. This predictive approach significantly improves first-pass yield.

Optimizing Heat Treatment Schedules

Based on solid-state transformation temperatures revealed by STA—such as precipitation, recovery, and recrystallization—we design scientifically grounded heat treatment schedules for printed parts. By tailoring heat treatment to the actual thermal response, we can precisely control the evolution of microstructure and enhance overall mechanical performance and stability.

Core Value of STA for AM Material Development and Quality Control

STA has transformed our approach to material development and process control. First, it shifts process design from traditional “trial-and-error” towards truly data-driven engineering. With accurate thermal data, we can predict material behavior under AM thermal cycles and significantly improve build reliability. Just as importantly, STA provides quantitative indicators for monitoring batch-to-batch consistency of thermal properties, helping ensure stable and repeatable production.

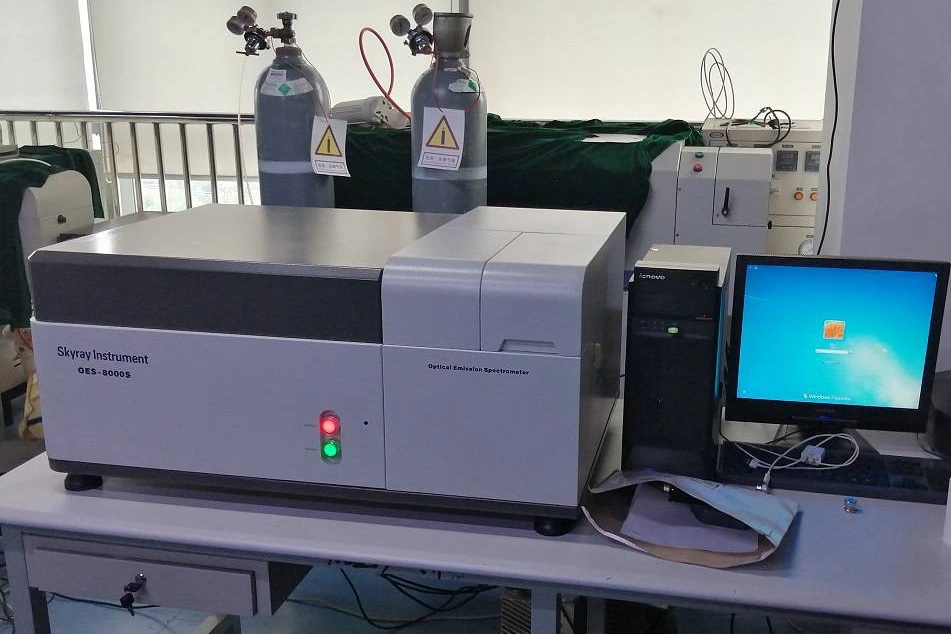

Synergy Between STA and Other Characterization Techniques

Coupling with Gas Analysis

By coupling STA with mass spectrometry, we not only capture mass loss steps and thermal events but also qualitatively identify evolved gases. This helps us distinguish, for example, whether a specific mass loss is due to dehydration, binder burnout, or chemical decomposition, providing deeper insight into reaction mechanisms and guiding process optimization.

Correlation with Phase Analysis

By quenching samples at characteristic STA temperatures and analyzing them via X-ray diffraction, we directly link thermal events to phase transformations. This correlation clarifies how microstructures evolve during heating and cooling, offering critical input for alloy design and process tailoring.

Closing the Loop with Mechanical Performance

We apply different heat treatment schedules derived from STA data to printed parts and then perform mechanical testing, building a complete link between thermal history, microstructure, and mechanical properties. This systematic methodology ensures our process optimization is always aligned with real-world performance requirements.

Case Study: How STA Optimized the HIP Process of a New High-Temperature Alloy

In an aerospace project, we developed a new nickel-based superalloy. However, when using a standard hot isostatic pressing (HIP) cycle, we observed abnormal grain growth in the parts. To identify the root cause, we conducted detailed STA tests on the alloy powder.

The DSC curve revealed a subtle exothermic peak occurring about 50°C lower than expected, without any corresponding mass change on the TG curve. Further analysis confirmed that this peak was associated with the premature dissolution or transformation behavior of γ′-strengthening phases, which increased grain boundary mobility and led to abnormal grain coarsening.

Based on the STA results, we adjusted the HIP temperature to stay below this critical transformation peak. The optimized process successfully suppressed abnormal grain growth while still achieving full densification. As a result, the improved procedure not only resolved the grain size issue but also significantly enhanced the alloy’s high-temperature performance, providing key technical support for the project’s success.

Conclusion: Using Thermal Insight to Reveal the Essence of AM Processes

Simultaneous thermal analysis, with its unique ability to couple mass and heat flow information, enables us to uncover the true thermal behavior of AM materials. At Neway, we firmly believe that fundamental materials research is the cornerstone of robust AM processes and reliable components. With STA, we elevate additive manufacturing from empirical “black-box” operation to a predictable, controllable, and scientifically grounded engineering discipline. We warmly invite partners engaged in new material development or process optimization to leverage our thermal analysis capabilities and jointly push the performance boundaries of additive manufacturing.

Frequently Asked Questions

How much sample is required for STA, and what are the requirements for sample form?

What is the sensitivity of TG? How small a mass change can it detect?

Which test atmospheres (e.g., N₂, Ar, air) are available for STA measurements?

What is the typical turnaround time from sample submission to receiving an STA test report?

Can STA be used to analyze the sintering behavior of ceramic materials?