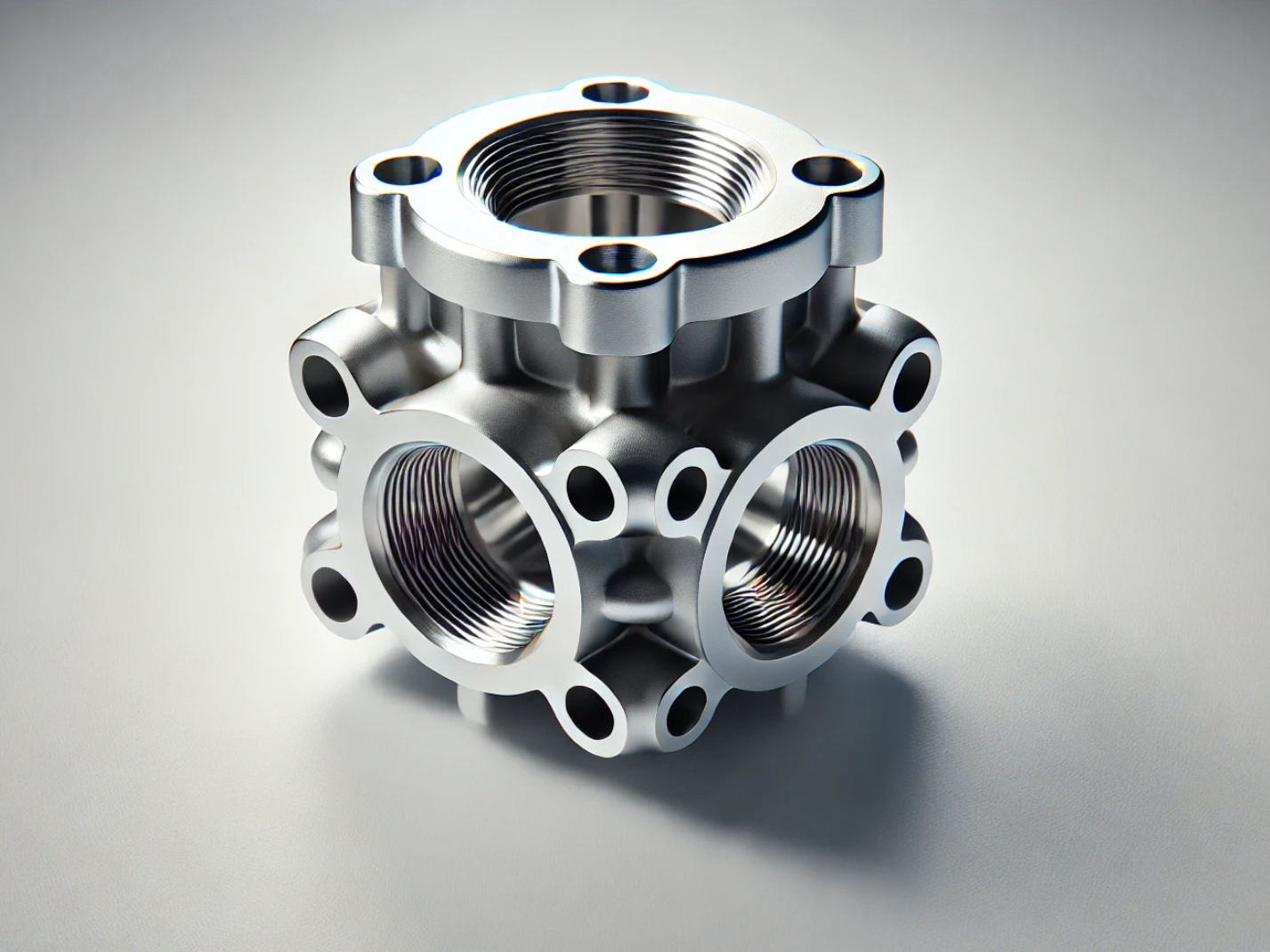

On-Demand Stainless Steel 3D Printing: Custom-Manufactured Valves for Oil and Gas Pipelines

Introduction

On-demand stainless steel 3D printing delivers a revolutionary solution for manufacturing high-strength, corrosion-resistant valves tailored for critical oil and gas pipeline operations. Utilizing advanced metal 3D printing technologies like Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS), robust stainless steels such as SUS316L and SUS420 ensure the mechanical integrity, corrosion resistance, and pressure handling needed in aggressive oilfield environments.

Unlike conventional forging and casting, stainless steel 3D printing for valves enables faster production cycles, intricate flow path optimization, reduced material waste, and on-demand customization for specialized oil and gas operations.

Applicable Material Matrix

Material | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | Corrosion Resistance | Max Operating Temp. (°C) | Oil and Gas Suitability |

|---|---|---|---|---|---|

570 | 485 | Excellent | 800 | Sour gas, corrosive fluids | |

520 | 220 | Very Good | 870 | General service valves | |

1000 | 880 | Good | 565 | High-pressure valves | |

1100 | 1000 | Moderate | 600 | Valve bodies for high-load | |

700 | 500 | Good | 650 | Valve seats, stems | |

650 | 450 | Moderate | 700 | Wear-resistant valve parts |

Material Selection Guide

SUS316L: Offering outstanding pitting and crevice corrosion resistance (PREN ~26), SUS316L is ideal for valves exposed to sour gas, chlorides, and aggressive chemical mixtures typical in upstream and midstream pipeline systems.

SUS304L: With very good corrosion resistance and high ductility, SUS304L is used for valves in less aggressive service conditions, such as general pipeline operations transporting crude oil and natural gas.

SUS15-5PH: Featuring high tensile strength (1000 MPa) and yield strength (880 MPa) after heat treatment, SUS15-5PH is perfect for high-pressure valve components operating in demanding environments.

SUS630/17-4PH: Offers superior strength (1100 MPa) and moderate corrosion resistance, making it suitable for valve bodies, bonnet parts, and actuator housings subjected to dynamic pressures.

SUS420: A martensitic stainless steel hardened to ~550 HV, SUS420 is selected for valve seats, gates, and stems that demand excellent wear resistance and moderate corrosion protection.

SUS410: Suitable for manufacturing durable valve trims, discs, and wear rings where moderate corrosion resistance and high surface hardness are required.

Process Performance Matrix

Attribute | Stainless Steel 3D Printing Performance |

|---|---|

Dimensional Accuracy | ±0.05 mm |

Density | >99.5% Theoretical Density |

Layer Thickness | 20–60 μm |

Surface Roughness (As-Printed) | Ra 5–15 μm |

Minimum Feature Size | 0.3–0.5 mm |

Process Selection Guide

Complex Flow Channel Optimization: 3D printing allows custom internal flow paths and pressure reduction channels to be integrated directly into valve bodies, improving flow efficiency and reducing erosion.

Superior Mechanical Strength: Precipitation-hardened stainless steels like SUS15-5PH and 17-4PH meet or exceed mechanical requirements for API valve classes.

Corrosion Resistance: Austenitic grades like SUS316L protect against sour service and chloride-induced cracking.

On-Demand Customization: Quickly produce non-standard valve sizes, specialty geometries, or repair parts, minimizing inventory and reducing downtime.

Case In-Depth Analysis: SUS316L 3D Printed Custom Choke Valve for Offshore Pipeline

An offshore oil and gas operator required corrosion-resistant choke valves capable of withstanding high-pressure, high-chloride environments. Using our stainless steel 3D printing service with SUS316L, we produced fully dense valve bodies featuring internal flow conditioners. The printed valves achieved tensile strength of 570 MPa, dimensional tolerances within ±0.05 mm, and outstanding resistance to sour gas and seawater corrosion. Post-processing included HIP treatment and passivation to meet NACE MR0175 compliance for sour service environments.

Industry Applications

Oil and Gas Pipelines

Custom choke valves, gate valves, and check valves.

High-pressure valve bodies for upstream, midstream, and downstream applications.

Valve trims and sealing elements for enhanced erosion and corrosion protection.

Offshore and Subsea Systems

Corrosion-resistant valves for subsea wellheads and manifolds.

Flow control devices in deepwater pipeline networks.

Petrochemical and Refinery Systems

High-temperature, high-pressure valves for chemical plants and processing systems.

Valves are used in sulfur recovery units, sour water systems, and acid gas treatment.

Mainstream 3D Printing Technology Types for Stainless Steel Valve Components

Selective Laser Melting (SLM): Best for precision, high-density valve bodies and internal flow control structures.

Direct Metal Laser Sintering (DMLS): Ideal for complex internal valve passages and customized seating geometries.

Binder Jetting: Suitable for rapid prototyping and small-batch production of stainless steel valve components.

FAQs

What stainless steel grades are best for 3D printed oil and gas valve components?

How does stainless steel 3D printing enhance flow optimization in valve design?

What post-processing is required for oil and gas-ready 3D printed valves?

Can 3D printed stainless steel valves withstand sour gas environments?

How does on-demand 3D printing minimize downtime in pipeline valve replacement?