Stainless steel 3D printing compared to traditional methods in terms of strength and performance?

Stainless Steel 3D Printing Compared to Traditional Methods in Terms of Strength and Performance

Comparable or Superior Mechanical Strength

3D printed stainless steel parts, particularly those made from SUS316L or SUS17-4PH, can achieve mechanical properties equal to or exceeding wrought or machined counterparts when properly processed. Using Powder Bed Fusion, tensile strengths typically range from 480 to 700 MPa for SUS316L and 850 to 1000 MPa for SUS17-4PH, matching or surpassing forged equivalents after heat treatment and HIP.

Enhanced Performance Through Design Freedom

Unlike traditional methods, additive manufacturing allows for weight-optimized lattice structures, internal cooling channels, and part consolidation. This enhances performance without compromising strength, especially in high-precision aerospace components or medical instruments.

Example: A traditionally machined manifold must be assembled from multiple parts, but a 3D printed version can be produced as a single monolithic part—reducing potential failure points and improving fluid flow and mechanical performance.

Fatigue and Corrosion Resistance

Corrosion Resistance: 3D printed stainless steels retain the corrosion-resistant properties of their base alloys. SUS316L, for example, remains highly resistant to chlorides and acids, comparable to conventionally manufactured parts.

Fatigue Resistance: As-printed parts may have surface roughness or internal defects that reduce fatigue life. However, applying HIP and surface treatments such as electropolishing significantly improves fatigue strength—often bringing it in line with or above machined stainless parts.

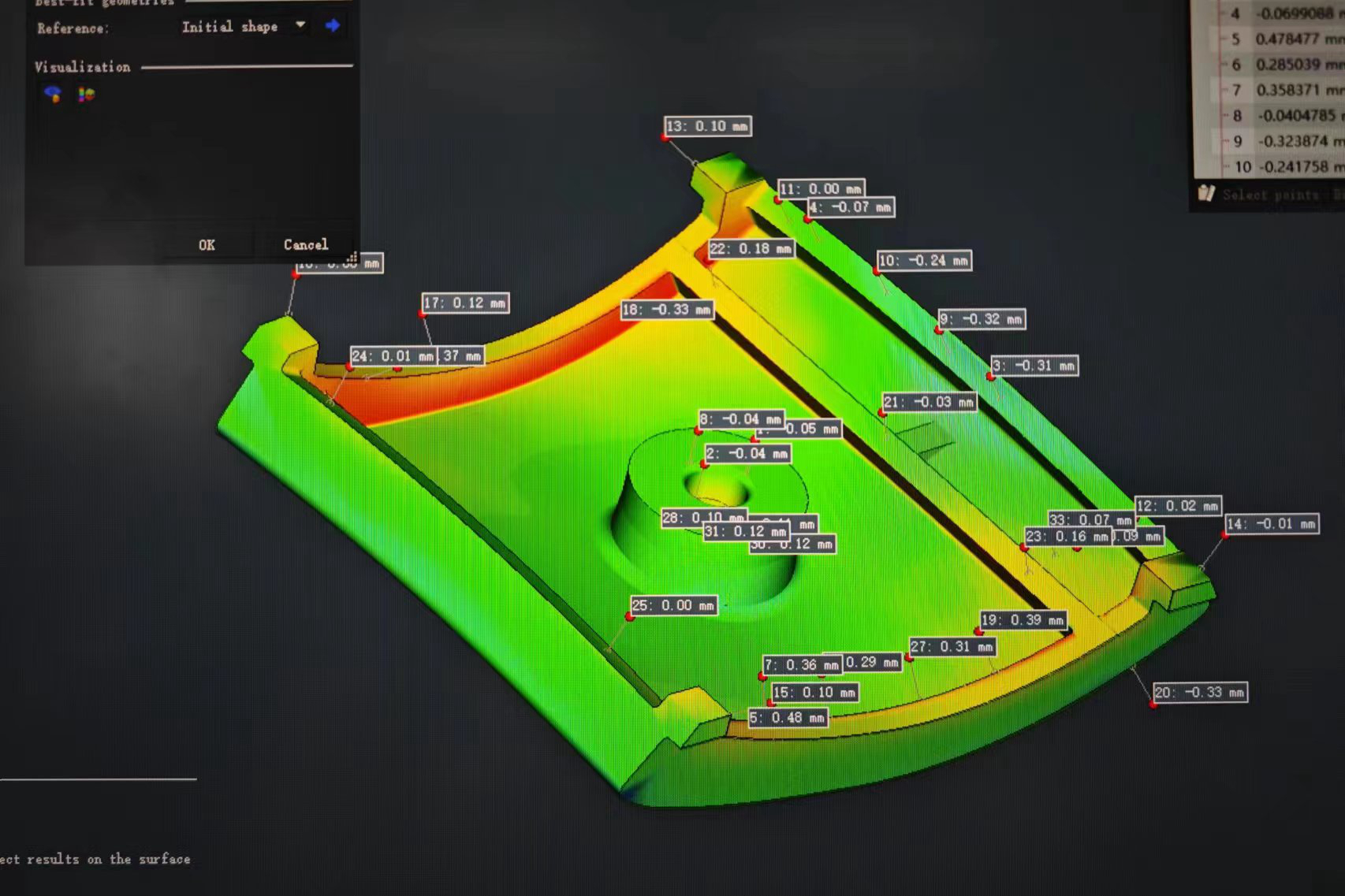

Dimensional and Microstructural Control

Additive parts offer tighter control over material distribution and microstructure through localized thermal input. With proper parameter tuning, stainless steel 3D prints exhibit fine grain structures and uniform phase distribution—comparable to or better than those in cast or sintered components.

Summary Comparison Table

Feature | 3D Printed Stainless Steel | Traditionally Manufactured Stainless Steel |

|---|---|---|

Tensile Strength | Up to 1000 MPa (post-processed) | 600–1000 MPa depending on alloy/form |

Fatigue Resistance | Comparable (with post-processing) | High (machined surface finish) |

Corrosion Resistance | Excellent (SUS316L, SUS304) | Excellent |

Design Freedom | High (lattices, internal channels) | Limited |

Lead Time (Low Volume) | Short (no tooling) | Long (tooling/setup required) |

Part Consolidation | Yes (one-step builds) | No (multi-part assemblies required) |

Recommended Stainless Steel Printing Services

SUS316L: For corrosion-resistant, structural applications

SUS17-4PH: For high-strength aerospace and tooling use

Heat Treatment and HIP: For strength, ductility, and fatigue improvement

CNC Machining: For high-tolerance surfaces and fatigue-critical zones