Which materials benefit most from HIP for increased density and strength?

Which Materials Benefit Most from HIP for Increased Density and Strength?

Overview

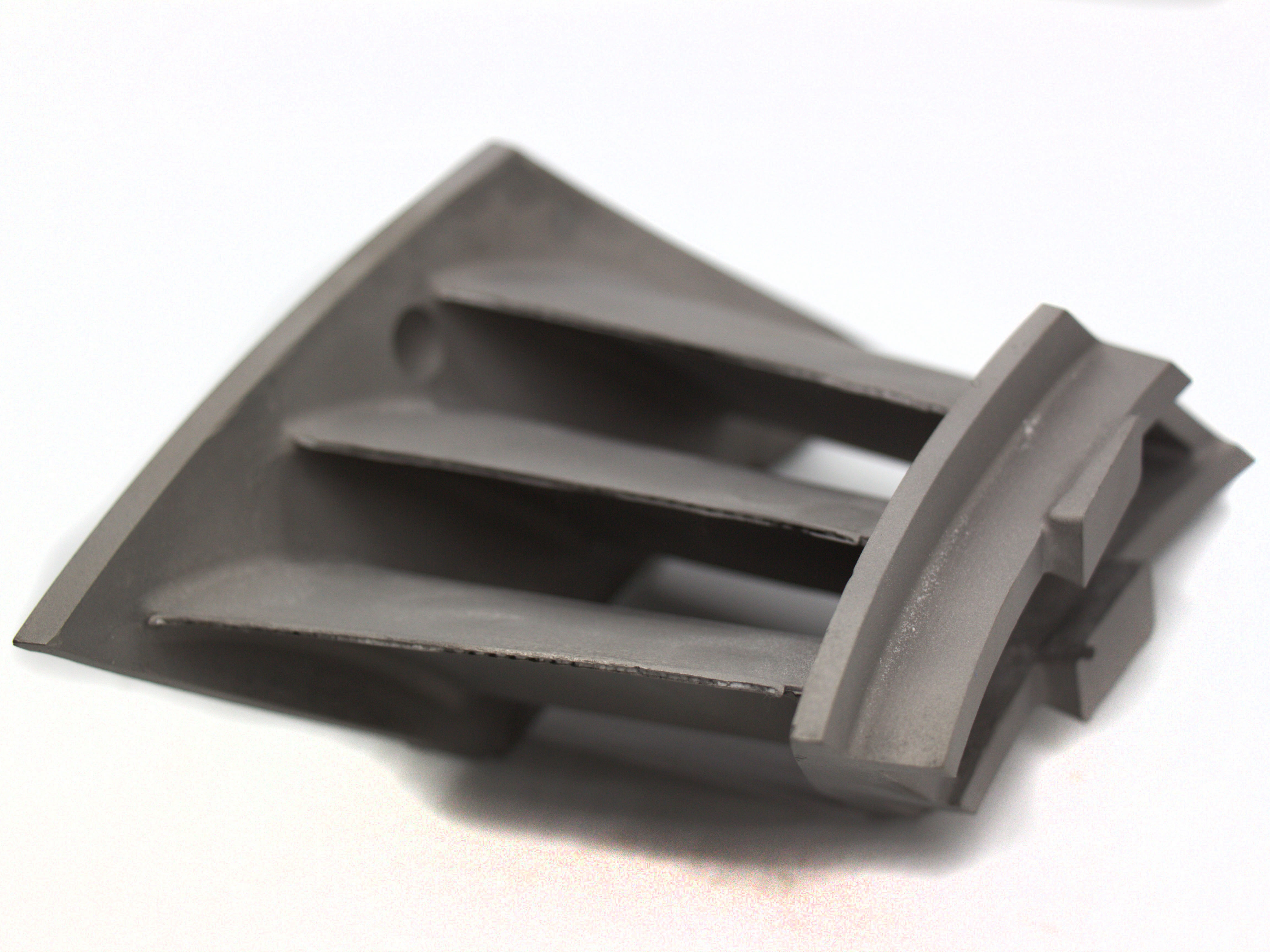

Hot Isostatic Pressing (HIP) is a critical post-processing method for metal 3D printed parts. It applies high pressure (typically 100–200 MPa) and elevated temperature (900–1250°C) in an inert atmosphere to eliminate internal porosity, improve density, and enhance fatigue and mechanical strength. HIP is especially effective for materials that exhibit microvoids, incomplete fusion, or high residual stress in as-printed condition.

1. Titanium Alloys

Best for: Aerospace and medical components requiring high fatigue strength and biocompatibility

Ti-6Al-4V and Ti-6Al-4V ELI (Grade 23): HIP at 920°C and ~100 MPa eliminates porosity and increases elongation and fracture toughness

Ti-6Al-2Sn-4Zr-2Mo: Critical for high-temperature aerospace structures where internal defects would compromise reliability

2. Nickel-Based Superalloys

Best for: High-temperature turbine, combustor, and structural components in aerospace and energy industries

Inconel 718: HIP at ~1180°C densifies the microstructure, improving fatigue life and creep resistance

Hastelloy X and Haynes 230: HIP ensures defect-free high-temperature parts for combustors and seals

3. Tool Steels

Best for: Mold cores, cutting tools, and dies where toughness and wear resistance are essential

Tool Steel 1.2709: Benefits from HIP + aging to achieve >50 HRC and consistent mechanical properties throughout the volume

Tool Steel H13: HIP stabilizes the microstructure before tempering, reducing fracture risk in high-stress tooling applications

4. Stainless Steels

Best for: Pressure-containing components, implants, and corrosion-resistant parts

SUS316L: HIP improves ductility and eliminates gas pores, critical for food-grade, marine, and biomedical uses

SUS630/17-4 PH: HIP prior to aging enhances dimensional stability and fatigue resistance

5. Aluminum Alloys

Best for: Lightweight structural components in aerospace and motorsports

AlSi10Mg: HIP improves ductility and fatigue strength by reducing microcracks and interlayer defects

Summary Table: Materials Best Suited for HIP

Material | Key Benefits from HIP |

|---|---|

Ti-6Al-4V / ELI | Eliminates porosity, improves fatigue life |

Inconel 718 | Increases creep and fatigue resistance |

Tool Steel 1.2709 | Uniform hardness, reduced brittleness |

SUS316L / 17-4 PH | Enhances corrosion resistance and toughness |

AlSi10Mg | Reduces internal defects, improves ductility |

Recommended HIP-Ready Services from Neway 3DP

Hot Isostatic Pressing (HIP) Eliminates porosity and enhances strength in mission-critical parts

Heat Treatment Follow-up tempering, aging, or annealing post-HIP for mechanical optimization

CNC Machining Final dimensional adjustment after thermal post-processing