What industries benefit most from HIP-treated 3D printed parts?

What Industries Benefit Most from HIP-Treated 3D Printed Parts?

Aerospace and Aviation

The aerospace industry demands components with high fatigue resistance, thermal stability, and near-zero porosity. HIP-treated parts, especially those made from superalloys such as Inconel 718 or Haynes 230, exhibit enhanced mechanical strength and dimensional stability. Applications include turbine blades, structural brackets, and combustion liners produced via Powder Bed Fusion. HIP ensures these parts maintain reliability under high temperatures and cyclic loading.

Medical and Healthcare

HIP processing plays a critical role in ensuring biocompatibility and mechanical integrity in complex 3D printed implants and surgical tools. Materials like Ti-6Al-4V ELI, commonly used in orthopedic and dental applications, benefit from HIP through reduced internal porosity and improved fatigue performance. The process also enhances ductility, making implants safer for long-term biological integration and mechanical endurance.

Energy and Power Generation

In energy applications—particularly nuclear and gas turbines—HIP enhances component lifespan by improving creep resistance, fracture toughness, and thermal stability. HIP-treated carbon steel and stainless steel parts are used in pressure vessels, impellers, and heat exchanger manifolds where internal porosity could lead to critical failure under pressure or heat. HIP eliminates these defects, ensuring parts meet ASME and ASTM high-pressure performance standards.

Automotive and Motorsports

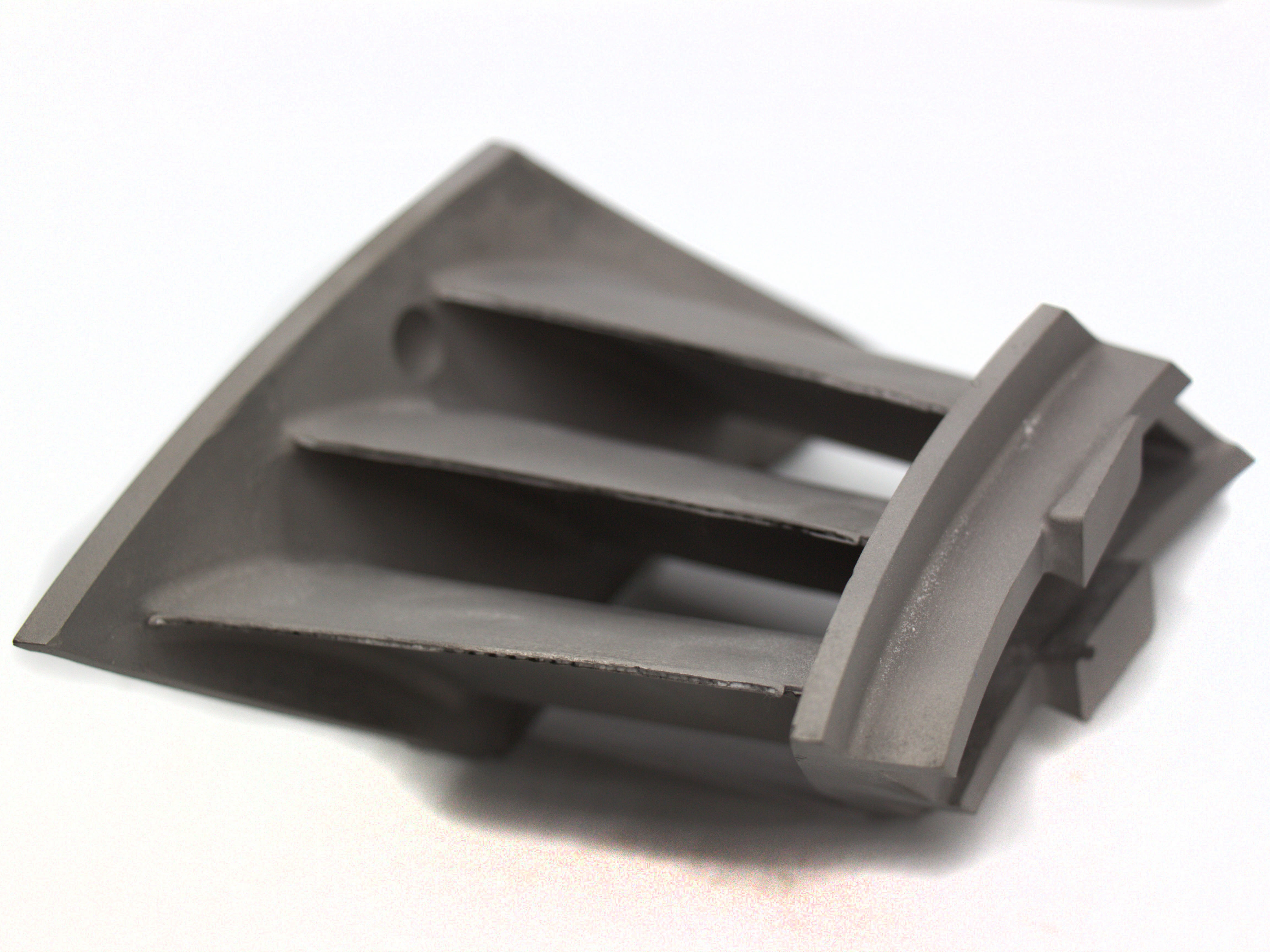

In motorsports and high-performance automotive applications, HIP is used to strengthen lightweight titanium and tool steel components. Components such as turbocharger housings, brake calipers, and transmission gears benefit from the fatigue resistance and hardness gains achieved through HIP. This results in longer service life and reduced failure risk under high RPM and thermal cycling conditions.

Recommended Services for Industry-Specific HIP Applications

To meet the performance requirements of demanding industries, Neway offers tailored solutions:

Industry-Focused 3D Printing:

Superalloy 3D Printing: For aerospace and energy-grade components.

Titanium 3D Printing: Used extensively in medical implants and motorsports parts.

Stainless Steel 3D Printing: Suitable for corrosion-resistant and high-load structural applications.

HIP and Heat Post-Processing:

Hot Isostatic Pressing (HIP): Ensures structural integrity for high-pressure, thermal, or cyclic loads.

Heat Treatment: Custom hardness and microstructure tuning by industry requirement.

Precision and Compliance Services:

CNC Machining: Ensures tight tolerances post-HIP for medical and aerospace standards.

Medical and Healthcare Solutions: Comprehensive compliance for biocompatible and certified components.