What are the primary benefits of HIP for parts exposed to high stress?

What Are the Primary Benefits of HIP for Parts Exposed to High Stress?

Complete Densification for Structural Integrity

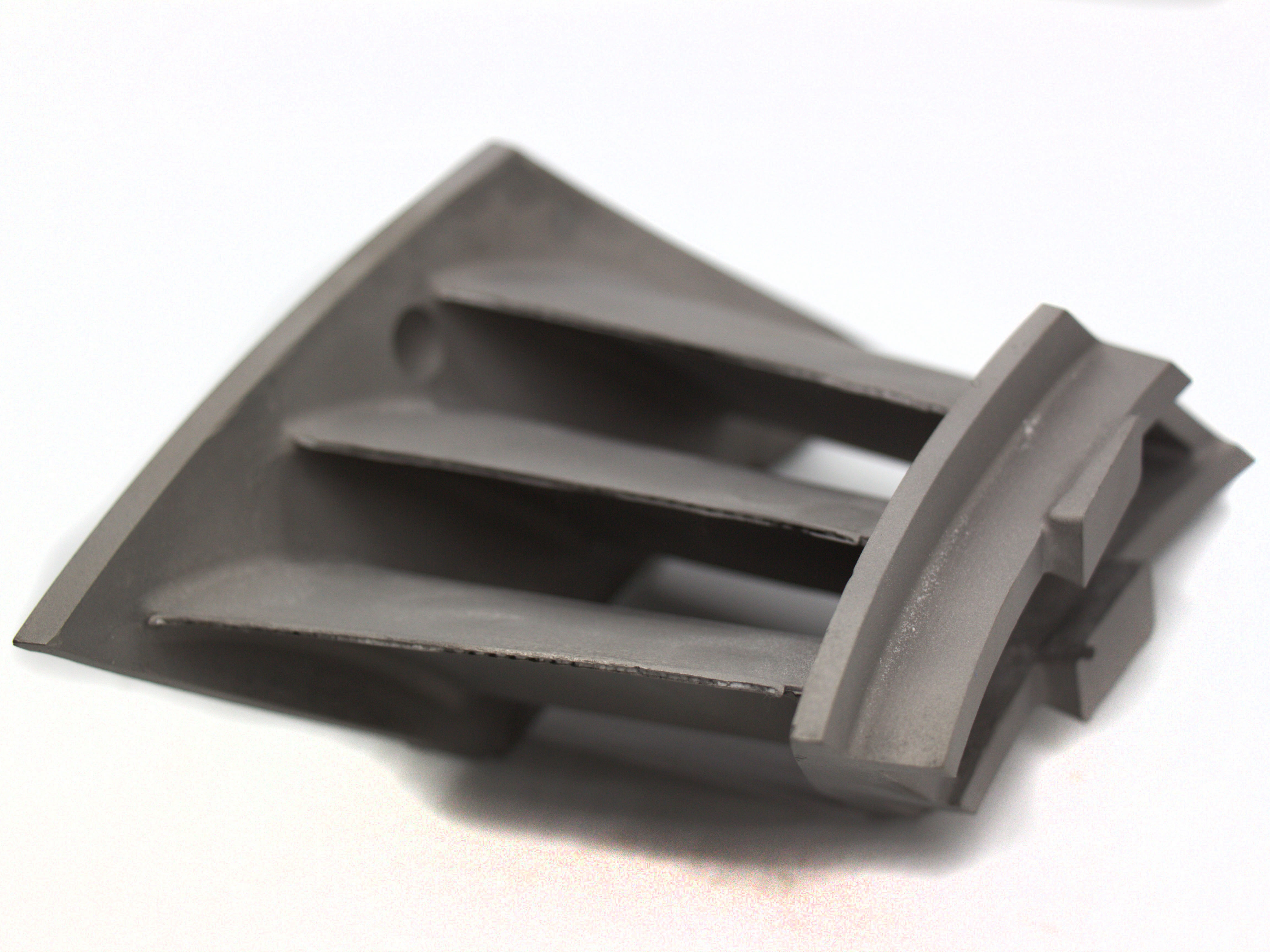

Hot Isostatic Pressing (HIP) provides full densification of metal 3D printed parts, which is essential for components subjected to high mechanical stress. By applying high pressure (typically 100–200 MPa) and temperature (900–1250°C) in a controlled atmosphere, HIP collapses internal pores and heals microcracks. This process results in parts with near-100% theoretical density, eliminating internal flaws that could act as crack initiation points under cyclic or impact loading.

Materials such as Inconel 625 and Ti-6Al-4V exhibit exceptional gains in reliability post-HIP, making them suitable for pressure vessels, turbine disks, and medical implants where structural integrity is critical.

Enhanced Fatigue Strength and Fracture Toughness

In high-stress applications, fatigue resistance is a primary failure concern. HIP has been shown to improve fatigue life by 2x to 10x, depending on material and geometry. For example, Stainless Steel SUS630 and Tool Steel H13 show substantial gains in endurance limit after HIP, particularly in components with complex shapes where surface or internal defects are not easily detected or removed.

By refining grain boundaries and eliminating shrinkage cavities, HIP also increases fracture toughness, allowing parts to withstand stress concentrations without catastrophic failure.

Dimensional Stability Under Thermal and Mechanical Load

In industries like aerospace and energy, where parts endure high temperatures and repeated mechanical loading, dimensional stability is vital. HIP relieves residual stresses accumulated during the printing process and helps prevent distortion or deformation during service. This is particularly important in large, load-bearing components produced via Superalloy 3D Printing or Carbon Steel 3D Printing.

Recommended Services for High-Stress Applications

For customers manufacturing components exposed to high stress or cyclic loading, Neway provides a complete solution through:

Material-Specific 3D Printing Capabilities:

Titanium 3D Printing: For lightweight, fatigue-resistant structural parts.

Superalloy 3D Printing: Ideal for turbine components and high-temperature service.

Carbon Steel 3D Printing: Suitable for shock- and wear-resistant tools and dies.

Stress-Optimized Post-Processing:

Hot Isostatic Pressing (HIP): Ensures porosity-free components with consistent mechanical performance.

Heat Treatment: Tailored thermal processing for further strength and hardness optimization.

Precision Finishing Services:

CNC Machining: Ensures geometric accuracy and tight tolerance control after HIP consolidation.