What post-processing steps are typically used for EDM parts?

What Post-Processing Steps Are Typically Used for EDM Parts?

1. Recast Layer and Heat-Affected Zone Removal

EDM creates a thin recast layer and a heat-affected zone (HAZ) on the surface of the machined part due to localized thermal discharge. These layers may contain microcracks or altered microstructures, which can reduce fatigue strength or corrosion resistance. To restore surface integrity, the following processes are used:

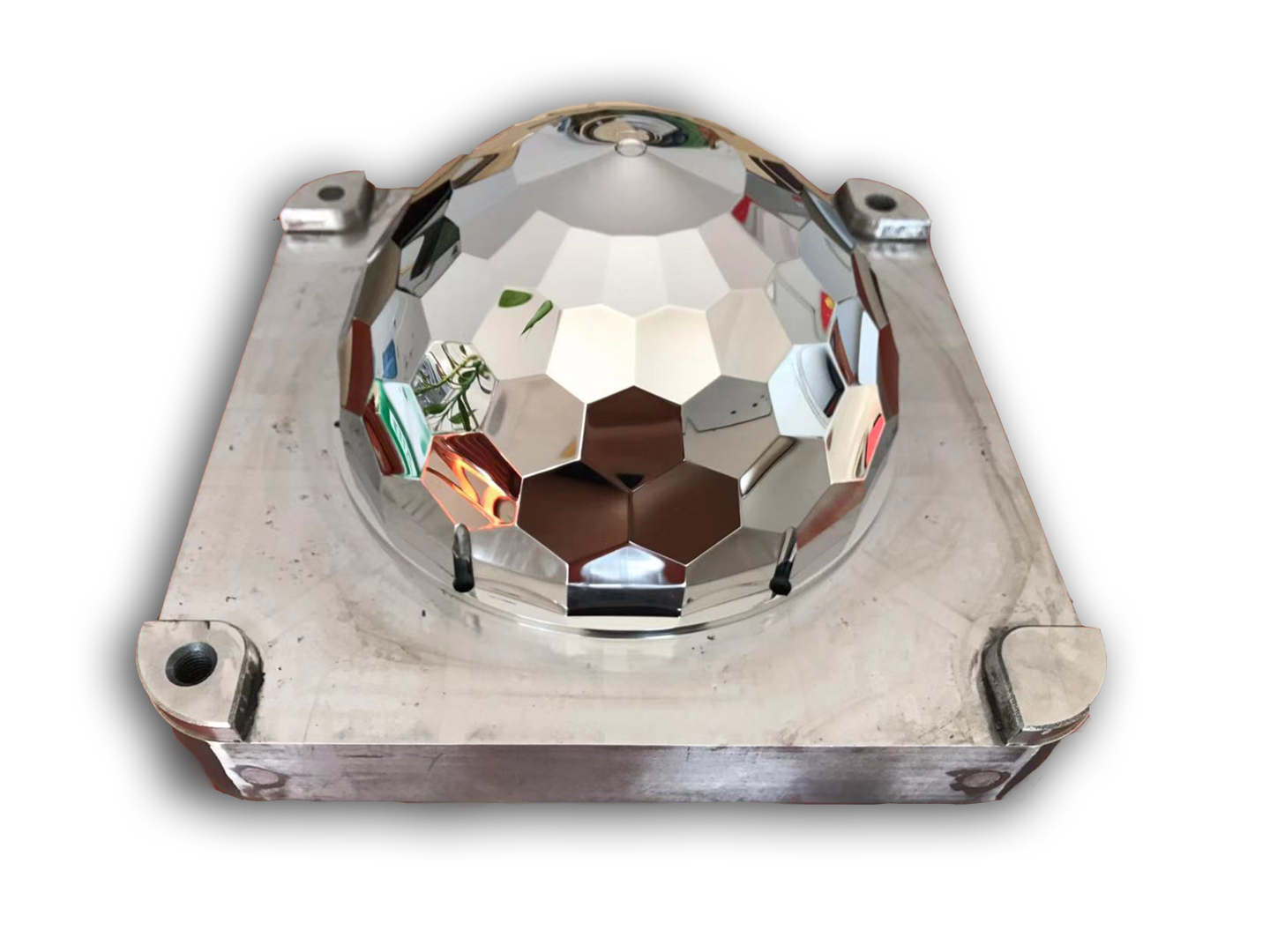

Polishing: Removes surface irregularities and enhances smoothness Polishing techniques improve both cosmetic and functional quality

Electropolishing: Uniformly dissolves surface material to remove the recast layer and micro-burrs Electropolishing enhances corrosion resistance and precision

Grinding or CNC finishing: Ensures dimensional tolerance and surface flatness See our CNC machining services for precision refinement

2. Heat Treatment

Heat treatment is often applied after EDM to relieve internal stresses and improve mechanical performance, especially for high-hardness materials like tool steels or superalloys.

Stress relief annealing

Hardening and tempering

Supports long-term dimensional stability and fatigue life Heat treatment services

3. Surface Treatment

Depending on the application, additional treatments may be used to enhance corrosion resistance, surface hardness, or aesthetic quality.

Passivation: Removes free iron and improves corrosion resistance of stainless steel Passivation

PVD coating: Adds a hard, wear-resistant ceramic surface layer PVD coating

Black oxide or nitriding: Improves wear resistance and surface hardness. See surface treatment services

4. Dimensional Inspection and Validation

EDM parts used in aerospace, medical, and tooling applications often require:

Coordinate Measuring Machine (CMM) inspection

Microscopy or dye penetrant inspection for surface cracks

Hardness and conductivity tests for performance-critical parts

Customer-Oriented Solutions and Services

To ensure EDM parts meet final specifications, we provide:

Complete Post-Processing Capabilities

From polishing to electropolishing, heat treatment, and CNC finishing

Application-Based Finishing

Surface Enhancement and Testing

With advanced surface treatment and in-process quality inspection for mission-critical parts