What are the applications of EDM mirror finishes in aerospace and medical industries?

Applications of EDM Mirror Finishes in Aerospace and Medical Industries

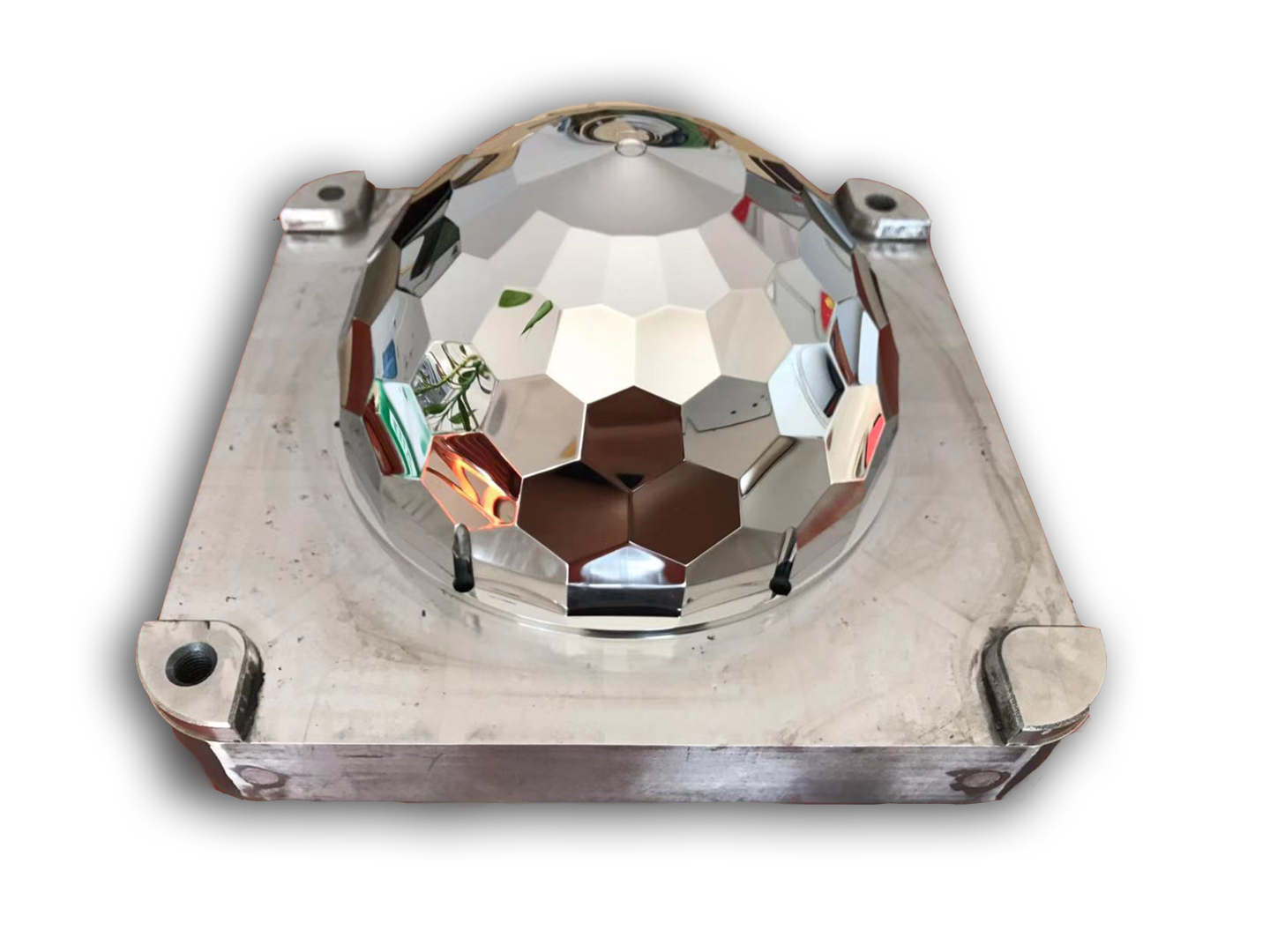

Aerospace Industry Applications

Turbine and Engine Components

In aerospace propulsion systems, components such as turbine blades, fuel nozzles, and combustion liners made from materials like Inconel 718, Hastelloy X, or Haynes 230 require exceptionally smooth surfaces to minimize flow resistance and thermal stress. EDM mirror finishing reduces surface roughness below Ra 0.2 µm, enhancing aerodynamic efficiency, fatigue life, and thermal stability.

Conformal Cooling and Internal Channels

EDM enables polishing of internal passageways in 3D printed parts produced by SLM or EBM, such as heat exchangers or nozzle interiors. This precision is critical in maintaining laminar flow and reducing carbon deposit accumulation in aerospace fluid systems.

Flight-Ready Structural Parts

Mirror-finished surfaces on structural parts made from Ti-6Al-4V (Grade 5) or Scalmalloy® improve fatigue resistance and surface integrity under cyclic loads, meeting aerospace-grade requirements like AS9100 and MIL-STD.

Medical Industry Applications

Implantable Devices

Medical implants such as orthopedic joints, spinal cages, and cranial plates manufactured from Ti-6Al-4V ELI (Grade 23) or SUS316L require ultra-smooth finishes to prevent tissue irritation and biofilm accumulation. EDM mirror finishing provides consistent Ra < 0.2 µm with no mechanical stress introduction.

Surgical Tools and Instruments

Complex instruments made from Tool Steel H13 or SUS630/17-4 PH benefit from EDM finishing for improved cutting precision, sterilization compatibility, and reduced particulate shedding during use.

Microfluidic and Diagnostic Devices

EDM’s ability to finish micro-scale internal channels and sharp-edged cavities is ideal for lab-on-chip devices and surgical fluid delivery systems. Smooth flow paths reduce clogging risks and enhance accuracy in fluidic control.

Post-Processing Services Recommended for Aerospace & Medical Parts

To ensure parts meet critical safety and performance standards, we offer:

EDM Machining Precision mirror finishing for deep, intricate, and tolerance-sensitive geometries.

Hot Isostatic Pressing (HIP) Improves internal density and mechanical performance of aerospace and implant-grade 3D printed parts.

Electropolishing Further enhances cleanliness, biocompatibility, and surface smoothness for medical-grade components.

We tailor finishing workflows to meet the highest aerospace and medical regulatory standards, ensuring safe and reliable end-use parts.