How precise can EDM machining be for 3D printed components?

How Precise Can EDM Machining Be for 3D Printed Components?

Tolerance Capabilities of EDM for Additive Parts

Electrical Discharge Machining (EDM) offers exceptional dimensional accuracy when post-processing 3D printed metal components. At Neway 3DP, standard EDM operations on additive parts achieve tolerances of ±0.005 mm, while optimized conditions and micro-EDM can reach ±0.002 mm. This is critical for aerospace, medical, and tooling applications that demand tight fits, sealing features, or micron-level mating surfaces.

Factors That Influence EDM Precision on 3D Prints

Surface Roughness of As-Printed Parts

Metal additive manufacturing processes such as SLM or DMLS often result in surface roughness between Ra 8–12 µm. EDM can reduce this to Ra ≤ 0.2 µm, creating smoother surfaces and precise contours. This is especially effective for high-performance alloys like Ti-6Al-4V or Inconel 718.

Geometry and Feature Size

EDM is particularly suited for fine-featured and complex geometries. Deep holes, thin walls, and internal channels in components like cooling inserts or implantable devices can be machined with precision, even at diameters below 0.3 mm, without compromising structural integrity.

Electrode and Setup Quality

Electrodes made from materials like Copper C110 or CuCr1Zr enable stable, repeatable spark control. Combined with high-resolution positioning systems, this ensures accuracy in each discharge cycle.

Precision Applications of EDM for 3D Printed Parts

Medical implants in Ti-6Al-4V ELI with ±0.003 mm tolerance

Turbine nozzle rings in Hastelloy C-276 with < ±0.005 mm tolerance

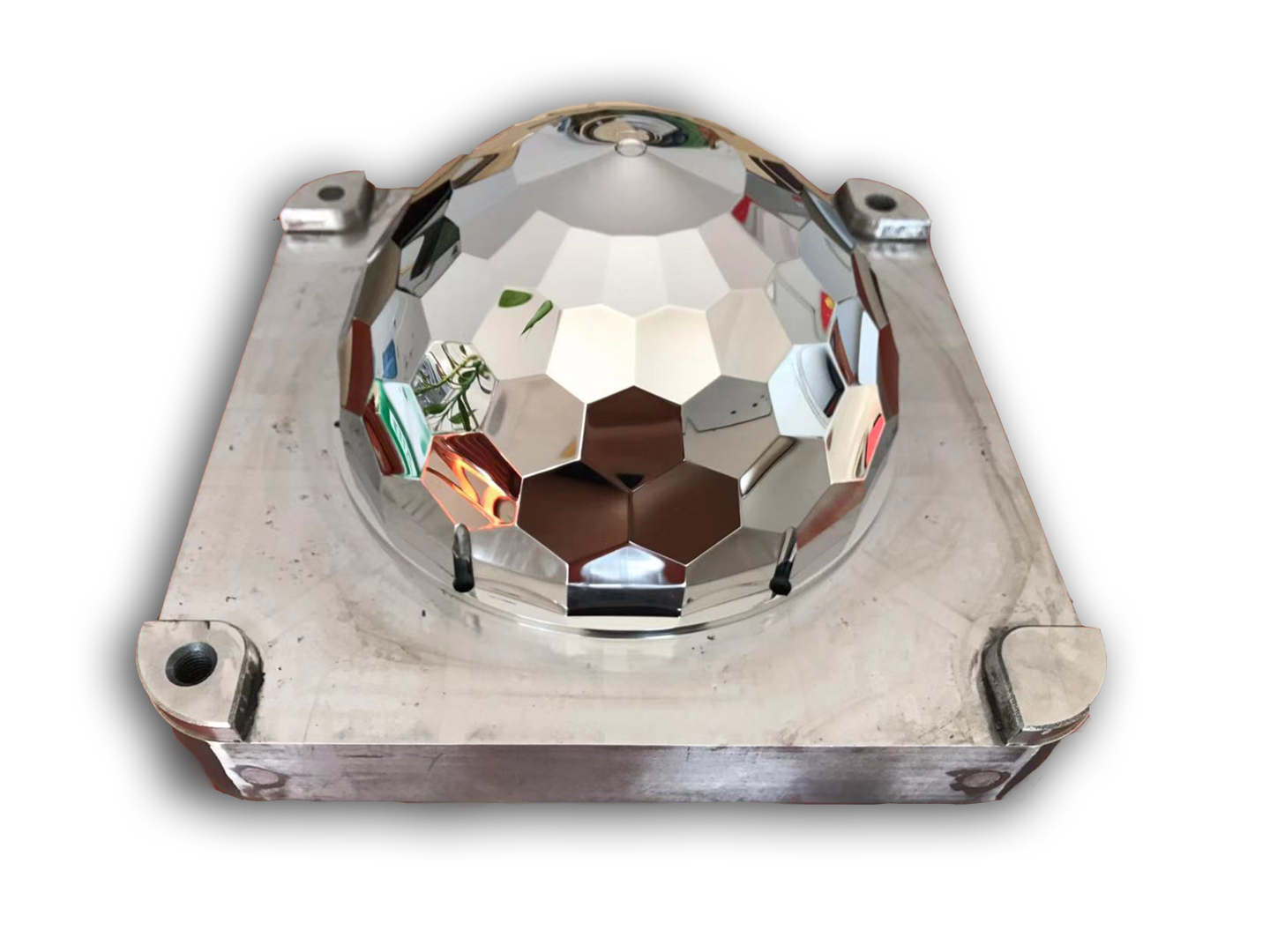

Tooling inserts in Tool Steel 1.2709 for plastic injection molds requiring sub-±0.002 mm alignment accuracy

Recommended Services for Dimensional Optimization

For additive parts requiring high-precision post-processing, we offer:

EDM Machining For exact geometry definition, fine finishing, and internal feature refinement.

CNC Machining For surface plane control and hybrid machining strategies.

Heat Treatment To stabilize structural properties before or after EDM, particularly for hardened alloys.

Neway 3DP ensures dimensional compliance and surface integrity across all 3D printed precision components.