How does EDM precision compare to traditional machining methods?

How EDM Precision Compares to Traditional Machining Methods

Dimensional Accuracy

EDM (Electrical Discharge Machining)

EDM consistently achieves ultra-fine tolerances down to ±0.002 mm. This level of accuracy is maintained even on hard-to-machine materials like Tool Steel H13, Inconel 718, and Ti-6Al-4V, and on complex geometries with high aspect ratios. As EDM is a non-contact process, it eliminates tool-induced mechanical deflection, which ensures stable precision even in thin-walled or intricate 3D printed features.

Traditional Machining

Conventional CNC milling or turning generally achieves tolerances of ±0.01 mm, and with high-end machines and optimized setups, down to ±0.005 mm. However, tool wear, cutting force deflection, and vibration become limiting factors when working with small features, high hardness materials, or delicate geometries.

Surface Finish Quality

EDM delivers superior surface finishes—Ra as low as 0.2 µm—especially with fine finishing settings. This is critical in finishing parts from additive processes such as SLM, where surface roughness must be significantly improved. In contrast, traditional machining often requires multiple passes and post-processing (grinding or polishing) to reach similar surface quality.

Capability on Complex Geometries

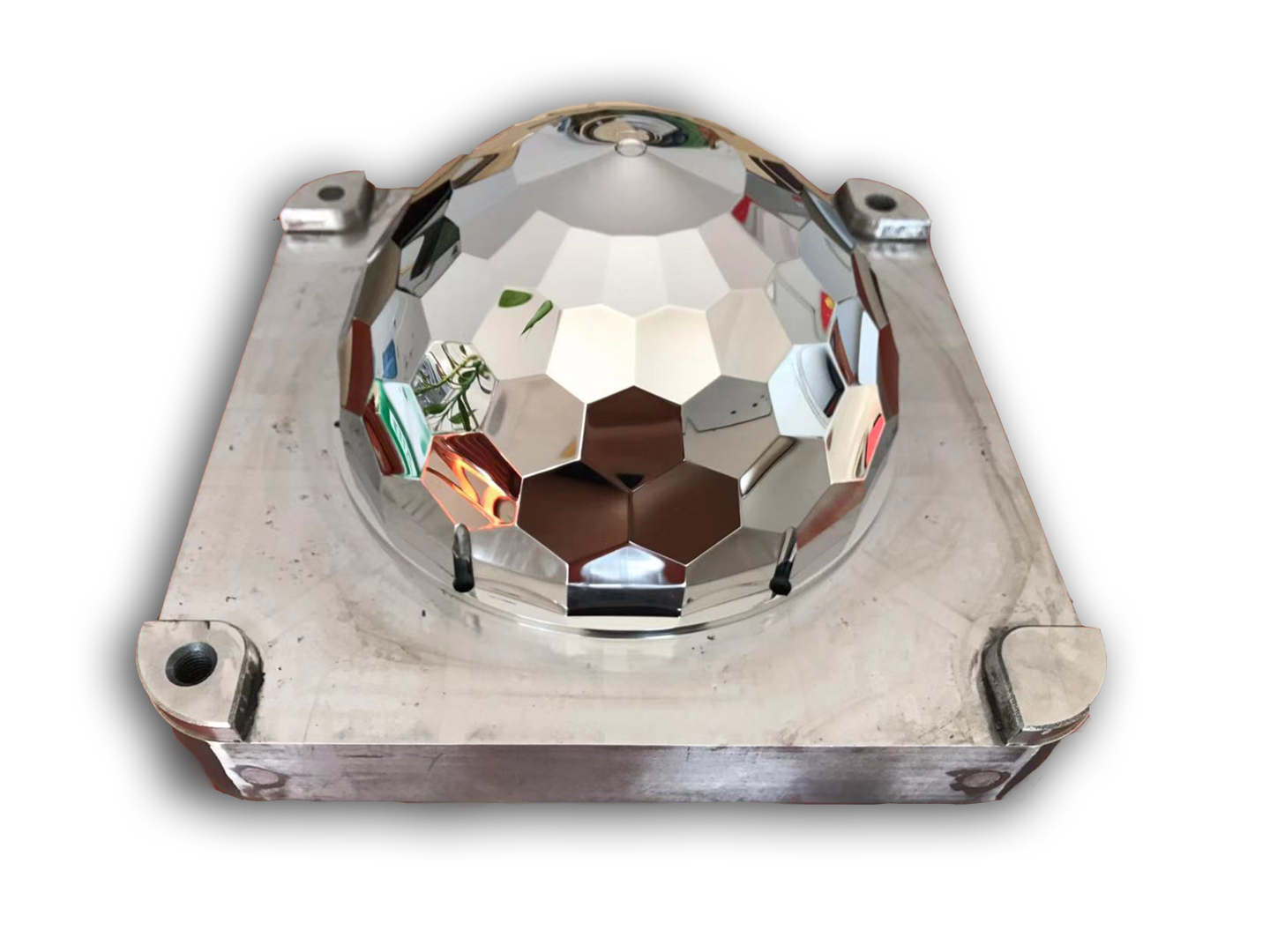

EDM outperforms traditional methods on complex internal cavities, sharp corners, deep holes, and undercuts—features often found in aerospace injectors, medical tools, and die inserts. Traditional machining tools have limited reach and are constrained by tool geometry and cutter path limitations.

Material Suitability

EDM easily handles ultra-hard or heat-resistant materials such as Tool Steel D2, Hastelloy X, and Ti-6Al-4V ELI (Grade 23), which pose challenges to traditional machining due to tool wear or thermal deformation.

Complementary Services for Precision Finishing

To optimize performance and surface accuracy across different processes, we recommend:

EDM Machining Achieve tight tolerances and finish intricate geometries not possible by traditional methods.

CNC Machining For higher speed processing and hybrid workflows where dimensional refinement is needed.

Electropolishing To enhance EDM finishes with improved surface uniformity and corrosion resistance.

Neway 3DP leverages both EDM and traditional machining, offering precision-tailored solutions based on part geometry, material, and functional requirements.