Tool Steel M2

M2 3D Printing Materials Introduction

Tool Steel M2 is a tungsten-molybdenum high-speed steel known for its exceptional red hardness, wear resistance, and compressive strength. It maintains cutting-edge integrity at elevated temperatures, making it ideal for high-speed machining tools, punches, and dies. With M2 3D printing, complex, high-performance tooling parts can be rapidly produced with excellent dimensional control, enabling extended service life and reduced post-processing in precision manufacturing.

M2 Similar Grades Table

Country/Region | Standard | Grade or Designation | Synonyms |

|---|---|---|---|

USA | ASTM | M2 | AISI M2 |

UNS | Unified | T11302 | - |

ISO | International | HS6-5-2 | - |

China | GB/T | W6Mo5Cr4V2 | - |

Germany | DIN/W.Nr. | 1.3343 | S6-5-2 |

M2 Comprehensive Properties Table

Category | Property | Value |

|---|---|---|

Physical Properties | Density | 8.15 g/cm³ |

Melting Point | 1420–1460°C | |

Thermal Conductivity (100°C) | 25.0 W/(m·K) | |

Electrical Resistivity | 82 µΩ·cm | |

Chemical Composition (%) | Carbon (C) | 0.85–0.90 |

Tungsten (W) | 5.50–6.75 | |

Molybdenum (Mo) | 4.50–5.50 | |

Chromium (Cr) | 3.75–4.50 | |

Vanadium (V) | 1.75–2.20 | |

Iron (Fe) | Balance | |

Mechanical Properties | Tensile Strength (quenched + tempered) | ≥1000 MPa |

Yield Strength (0.2%) | ≥850 MPa | |

Hardness (HRC) | 60–66 | |

Modulus of Elasticity | 210 GPa |

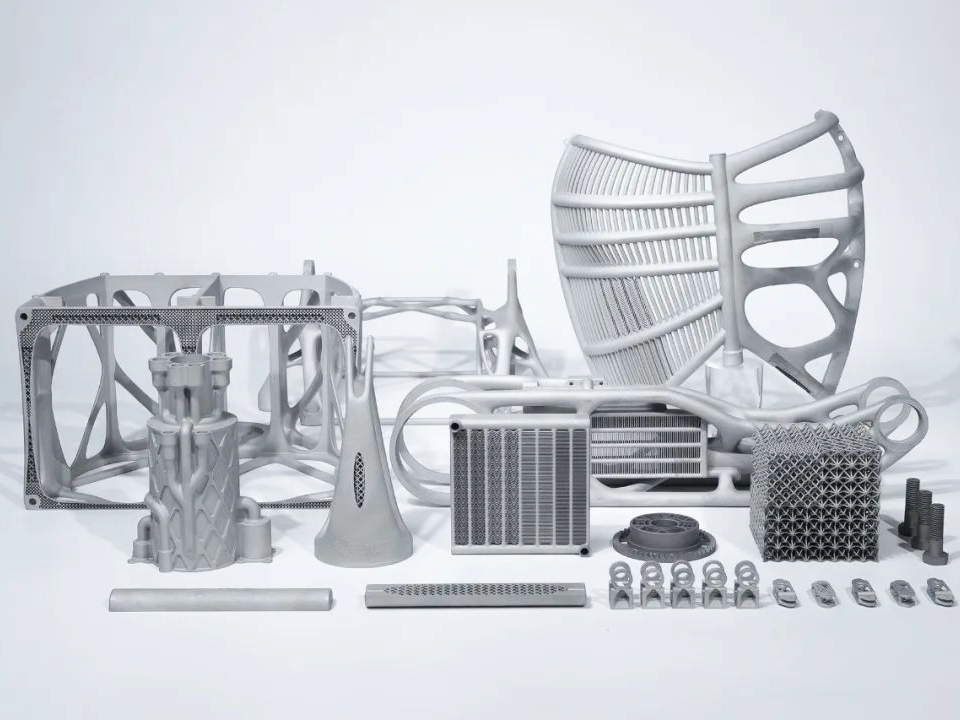

3D Printing Technology of M2

Tool Steel M2 is compatible with Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), and Electron Beam Melting (EBM). These methods enable precise fabrication of M2 parts with high hardness and superior temperature performance.

Applicable Process Table

Technology | Precision | Surface Quality | Mechanical Properties | Application Suitability |

|---|---|---|---|---|

SLM | ±0.05–0.1 mm | Excellent | Excellent | Cutting Tools, Molds, Punches |

DMLS | ±0.05–0.1 mm | Very Good | Excellent | Forming Dies, Taps, Broaches |

EBM | ±0.1–0.3 mm | Good | High-Temp Resilience | Thick-Walled Cutting & Form Tools |

M2 3D Printing Process Selection Principles

SLM is preferred for tight-tolerance tools requiring high edge retention, producing densities >99.5% and microstructural uniformity for high wear performance. DMLS allows the integration of coolant channels and custom tool geometries with minimal post-processing and consistent mechanical integrity. EBM is ideal for producing heavy-duty tools where thermal cycling resistance and toughness outweigh ultra-fine resolution.

M2 3D Printing Key Challenges and Solutions

Due to high carbide content, M2 is prone to internal stress cracking. Post-print tempering and quenching between 550–570°C ensures hardness and dimensional stability. CNC machining is recommended for sharpening tool profiles and achieving tolerance control within ±0.01 mm on cutting edges and mating features. Surface porosity or roughness may hinder performance. Electropolishing improves cutting efficiency and reduces tool friction under dry or high-speed conditions. Passivation enhances corrosion resistance, especially when tools operate in humid or chemically reactive environments.

Typical Post-Processing for M2 3D Printed Parts

Quenching and Tempering delivers hardness up to HRC 66, enhancing high-temperature tool life and wear performance. CNC Machining refines contours and ensures accurate fits for assembly-critical or cutting-edge sections. Electropolishing enhances performance by achieving Ra <0.6 µm on tool faces and improving chip evacuation. Passivation improves tool longevity in corrosion-prone environments by restoring the chromium oxide protective surface layer.

Industry Application Scenarios and Cases

Tool Steel M2 is widely used in:

Cutting Tools: Drills, end mills, and lathe inserts requiring high wear resistance and temperature tolerance.

Precision Punching: Broaches, punches, and stamping dies used in progressive dies and high-volume forming.

Molds and Dies: Cavity inserts and complex form tools used in injection molding and extrusion. A precision tooling case showed 3D printed M2 broaches with SLM, tempered to 62 HRC, reducing delivery time by 50% and increasing cutting cycles by 40%.

FAQs

What is the maximum hardness of M2 tool steel after 3D printing and heat treatment?

Is M2 suitable for high-speed cutting applications when 3D printed?

How does M2 compare to D2 in wear resistance and red hardness?

What heat treatments are required to optimize 3D printed M2 tool steel?

Can M2 3D printed tools match the life cycle of conventionally manufactured ones?