Tool Steel 1.2709

1.2709 3D Printing Materials Introduction

Tool Steel 1.2709 is a high-performance tool steel known for its high toughness, excellent wear resistance, and thermal fatigue properties. It is particularly well-suited for demanding applications such as aerospace, automotive, and injection molding tools.

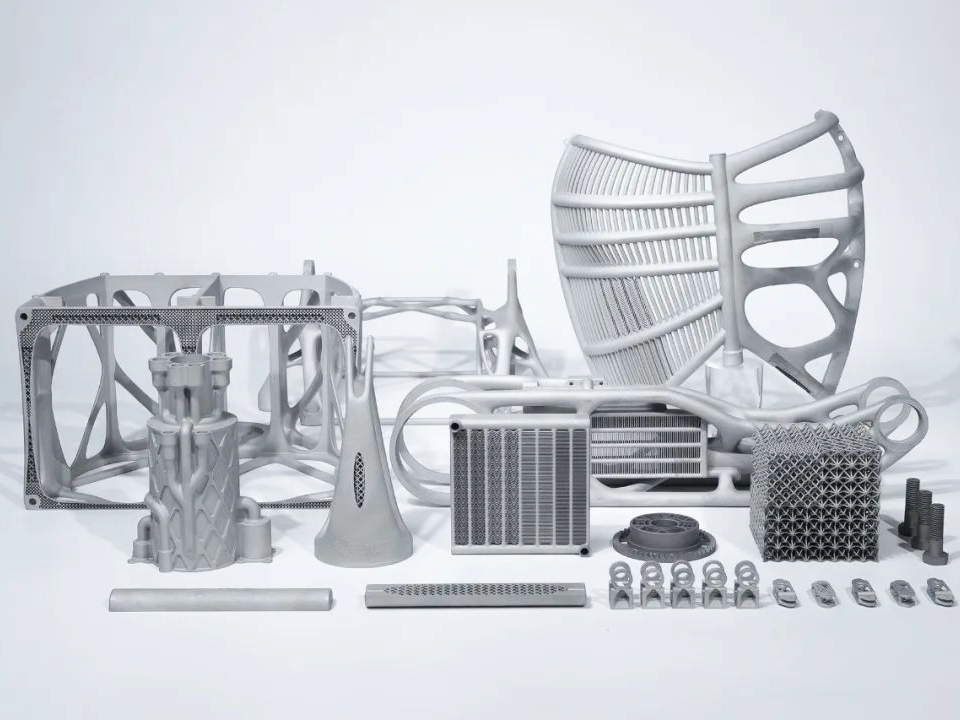

1.2709 3D printing allows for the production of complex, lightweight components that maintain the mechanical properties of traditionally forged tooling, delivering enhanced performance in high-temperature and high-stress environments.

1.2709 Similar Grades Table

Country/Region | Standard | Grade or Designation | Synonyms |

|---|---|---|---|

USA | ASTM | 1.2709 | AISI 1.2709, DIN 1.2709 |

UNS | Unified | T20809 | - |

ISO | International | 1.2709 | - |

China | GB/T | 5CrNiMo | Cr5NiMo |

Germany | DIN/W.Nr. | 1.2709 | - |

1.2709 Comprehensive Properties Table

Category | Property | Value |

|---|---|---|

Physical Properties | Density | 7.75 g/cm³ |

Melting Point | 1430°C | |

Thermal Conductivity (100°C) | 30.5 W/(m·K) | |

Electrical Resistivity | 75 µΩ·cm | |

Chemical Composition (%) | Carbon (C) | 0.30–0.40 |

Chromium (Cr) | 5.50–6.50 | |

Nickel (Ni) | 1.00–1.50 | |

Molybdenum (Mo) | 0.80–1.20 | |

Iron (Fe) | Balance | |

Mechanical Properties | Tensile Strength | 1200 MPa |

Yield Strength (0.2%) | 850 MPa | |

Hardness (HRC) | 48–52 HRC | |

Modulus of Elasticity | 205 GPa |

3D Printing Technology of 1.2709

Tool Steel 1.2709 is suitable for 3D printing using Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), and Electron Beam Melting (EBM). These technologies provide excellent part density, fine surface finish, and superior mechanical properties, especially in tooling applications where precision and high temperature resistance are required.

Applicable Process Table

Technology | Precision | Surface Quality | Mechanical Properties | Application Suitability |

|---|---|---|---|---|

SLM | ±0.05–0.1 mm | Excellent | High Temperature | Aerospace, Injection Molds |

DMLS | ±0.05–0.1 mm | Very Good | Excellent | Tooling, Complex Geometries |

EBM | ±0.1–0.3 mm | Good | High-Temp Resilience | Large Components, Heavy-Duty Molds |

1.2709 3D Printing Process Selection Principles

Selective Laser Melting (SLM): SLM is ideal for producing highly detailed, complex geometries and producing parts with superior mechanical properties. This technology is perfect for creating tooling components with high density and excellent heat resistance.

Direct Metal Laser Sintering (DMLS): DMLS is a preferred technology for 3D printing 1.2709, as it provides high-precision parts that are capable of withstanding extreme stress and heat. This technology ensures tight tolerances and excellent thermal stability.

Electron Beam Melting (EBM): EBM is particularly useful for large parts requiring high-temperature resilience. The electron beam process creates highly dense parts with low residual stresses, making it ideal for heavy-duty tooling like die-casting molds.

1.2709 3D Printing Key Challenges and Solutions

Residual Stress and Distortion: High carbon content in 1.2709 can lead to residual stress during printing. Pre-heating the powder bed and post-process stress relief annealing at 600–650°C for 2 hours can minimize these stresses and prevent distortion.

Surface Roughness: Electropolishing can reduce surface roughness to Ra 1.0 µm, which improves the quality and functionality of tooling components, particularly in applications that demand high surface finish standards.

Porosity: DMLS minimizes porosity and ensures better fusion between layers, which results in denser and stronger parts suitable for tooling applications. Fine powder and controlled heat parameters during the build help achieve this.

Corrosion Resistance: Although 1.2709 offers moderate corrosion resistance, further passivation can improve its ability to withstand corrosion in high-stress environments, ensuring the longevity of tooling in industries like automotive and aerospace.

Typical Post-Processing for 1.2709 3D Printed Parts

Quenching and Tempering: Heat treatment at 1050°C followed by tempering at 520°C enhances the hardness of 1.2709, reaching HRC 48–52, ideal for tooling components that undergo high-pressure conditions.

CNC Machining: CNC machining is crucial for achieving tight tolerances of ±0.02 mm, especially for parts with fine geometries, which require high precision, like complex mold cavities and intricate tooling parts.

Electropolishing: Electropolishing helps reduce the surface roughness to Ra 1.0 µm, which enhances mold release and improves the aesthetic and functional quality of 1.2709 parts used in tooling and molding applications.

Passivation: Passivation increases corrosion resistance by forming a protective layer on the surface, reducing the risk of rust and extending the lifespan of tooling parts exposed to aggressive environments.

Industry Application Scenarios and Cases

1.2709 is used in:

Aerospace: Molds and dies for manufacturing turbine blades and engine components that require high strength and thermal stability.

Automotive: Hot work tooling such as forging dies, extrusion dies, and injection molds.

Molding: Complex injection molds for plastic and rubber components, where high precision and wear resistance are required. A case study from the aerospace industry demonstrated that 1.2709 3D printed components reduced tooling lead times by 35% and improved tool longevity by 25%.

FAQs

What are the key benefits of using Tool Steel 1.2709 for 3D printed tooling parts?

How does 1.2709 3D printing compare to traditional manufacturing methods for molds?

What post-processing techniques are required for 1.2709 3D printed parts?

How does 1.2709 withstand high temperatures in aerospace and automotive applications?

Can 1.2709 be used for producing large tooling components in heavy-duty industries?