DMS Ultra Trace Purity For Aerospace Grade-3d Printed Parts

Introduction: The Purity Revolution for Aerospace-Grade 3D Printing – DMS Ultra-Trace Purity

In the aerospace sector, the failure of any single component can lead to catastrophic consequences. As materials engineers at Neway, we fully understand the decisive impact of material purity on part performance. Especially in metal additive manufacturing, traditional processes may rely on subsequent machining to improve material properties, whereas the layer-by-layer nature of 3D printing makes the intrinsic purity of the material the fundamental determinant of part quality. This is why we have introduced DMS Ultra-Trace Purity technology—a revolutionary quality control system specifically designed to ensure the material purity of aerospace-grade superalloy parts, providing unprecedented reliability for critical applications.

What Is DMS Ultra-Trace Purity Technology?

Technical Definition and Core Objective

DMS Ultra-Trace Purity technology is a comprehensive material analysis and control system designed to precisely detect and strictly control specific trace elements in metal powders. At Neway, we define “ultra-trace” as controlling critical impurity elements such as sulfur, oxygen, and nitrogen down to the parts-per-million level. This system is not just a testing tool; it is a full lifecycle purity management solution, covering everything from raw materials to finished parts. Through DMS technology, we ensure that every batch of metal powder used for aerospace component manufacturing meets the most demanding purity standards.

Why Are Trace Elements So Critical?

In aerospace applications, materials must withstand extreme temperatures, pressures, and loads. Taking high-temperature superalloys as an example, even ppm-level sulfur can form brittle sulfides at grain boundaries, significantly reducing creep resistance and long-term strength. Likewise, excessive oxygen and nitrogen contents lead to the formation of oxides and nitrides. These brittle phases serve as initiation sites for fatigue cracks, posing a severe threat to the structural integrity and service life of aerospace components.

How Neway Achieves and Secures DMS Ultra-Trace Purity

Source Control: High-Purity Raw Materials and Advanced Atomization

Purity control must start at the source. We select high-purity raw materials and further refine them using technologies such as vacuum induction melting. In the powder production stage, we adopt advanced inert gas atomization systems to minimize exposure of molten metal droplets to oxygen during solidification. The entire atomization process is conducted under inert atmosphere protection to physically isolate potential contaminants. This rigorous source control establishes a solid foundation for the quality of our subsequent metal powders.

Full-Process Monitoring: Purity Tracking from Powder to Finished Part

Every stage from powder shipment to part fabrication carries purity risks. To address this, we have established a full-chain inert atmosphere protection system. Powders are transported in sealed containers, and storage conditions are maintained at a consistently low dew point. During use, automatic sieving and conveying systems are employed to minimize human intervention. More importantly, each powder batch undergoes DMS analysis before use, and only powders that fully comply with purity specifications are released into production.

Key Control Points of DMS Ultra-Trace Purity in the 3D Printing Process

Pre-Printing: Powder Batch Qualification and Equipment Environment Preparation

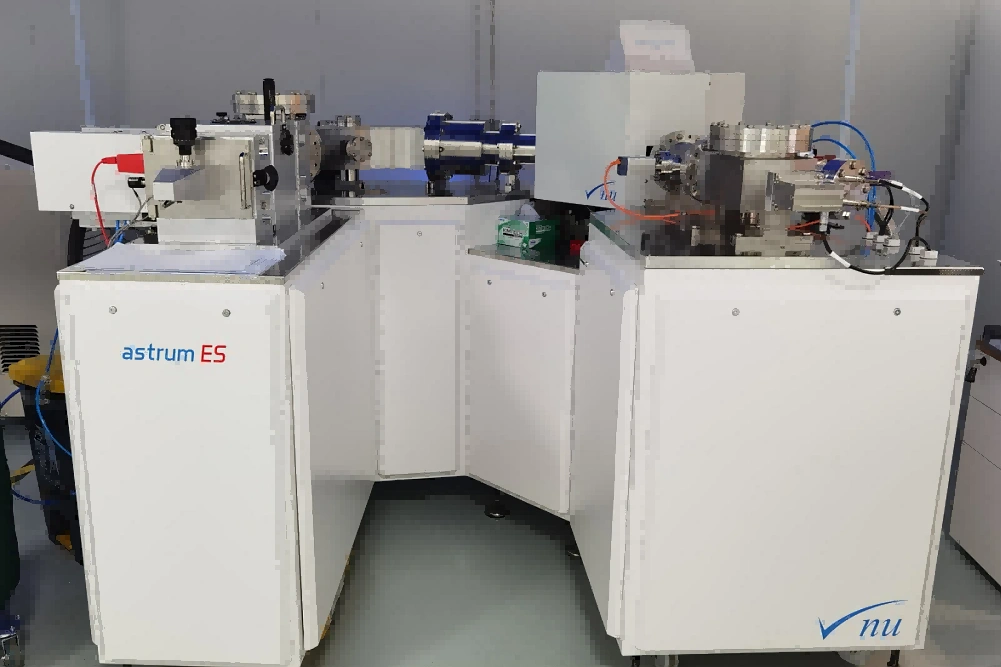

Before printing starts, we use high-precision carbon-sulfur analyzers to rapidly verify that the sulfur content in the powder meets aerospace standards. At the same time, we implement strict environmental control for powder bed fusion equipment, maintaining oxygen levels in the build chamber below 10 ppm and moisture at or below a -40°C dew point, thereby preventing oxidation of powders during processing.

In-Process Printing: Parameter Optimization to Maintain Material Purity

Process parameters during printing directly affect the purity of the final material. Through extensive process development, we have optimized laser power, scan speed, and scan strategies to ensure a stable melt pool and minimal spatter. Excessive energy input can cause selective evaporation of alloying elements, while insufficient energy may lead to lack-of-fusion defects. Our process experts define optimal process windows for each material to achieve both high density and stable purity.

Post-Printing: Verification of Final Chemical Composition

After printing, we sample parts from the same production batch and perform comprehensive chemical composition analysis using direct-reading spectrometers. This is not only a confirmation of powder purity but also a verification of the effectiveness of purity control throughout the entire manufacturing process. All data are fully recorded and reflected in the quality certificates, providing customers with complete material traceability.

Key Aerospace Applications Enabled by DMS Technology

Ultra-Pure Components in Jet Engines

For hot-section components in jet engines, Inconel 718 and Hastelloy X parts produced under DMS control exhibit exceptional high-temperature performance. By strictly limiting the sulfur content to below 20 ppm and the oxygen content to below 50 ppm, the turbine blades and vane components we manufacture maintain stable microstructures and mechanical properties at operating temperatures of up to 700°C.

High-Strength Materials for Spacecraft Structures

For spacecraft structural components, we apply DMS-controlled Ti-6Al-4V, with the oxygen content precisely maintained in the optimal range of 1300–1500 ppm. This fine control ensures a balance of high strength and fracture toughness. The titanium alloy structures we supply for satellites and space probes deliver lightweight performance while withstanding severe launch vibrations and extreme in-orbit thermal cycling.

DMS Ultra-Trace Purity, Industry Standards, and Certifications

Our DMS Ultra-Trace Purity control system fully complies with the most stringent aerospace material standards, including AMS 4992 and AMS 4994, as well as relevant NASA specifications. This system represents a targeted enhancement of our ISO 9001 quality management system in the area of material control, serving as a key technical foundation for our AS9100 aerospace quality management certification. With DMS technology, we not only meet standard requirements but also surpass industry averages across multiple critical indicators.

Conclusion: Material Science Engineered for Extreme Reliability

In aerospace, where reliability is non-negotiable, material purity is no longer optional—it is essential. DMS Ultra-Trace Purity technology represents the current pinnacle of material control in metal additive manufacturing and is the technological cornerstone for producing true aerospace-grade 3D-printed components. At Neway, we believe that our relentless pursuit of purity is the strongest commitment we can make to the safety and reliability of our customers’ products. We invite all partners in the aerospace and aviation sectors to experience our custom part manufacturing services empowered by DMS Ultra-Trace Purity technology and to join us in pushing the boundaries of aerospace manufacturing.

Frequently Asked Questions

Which specific trace elements are typically targeted by DMS Ultra-Trace Purity control?

How much does this technology increase the cost of metal 3D printing services?

What is your testing frequency and acceptance criteria for powder purity?

Is DMS technology applicable to all types of metallic materials?

How can DMS-based purity control be traced and reflected in my part quality reports?