UAM 3D Printing Service: Multi-Material Superalloy Parts Without Melting

Introduction

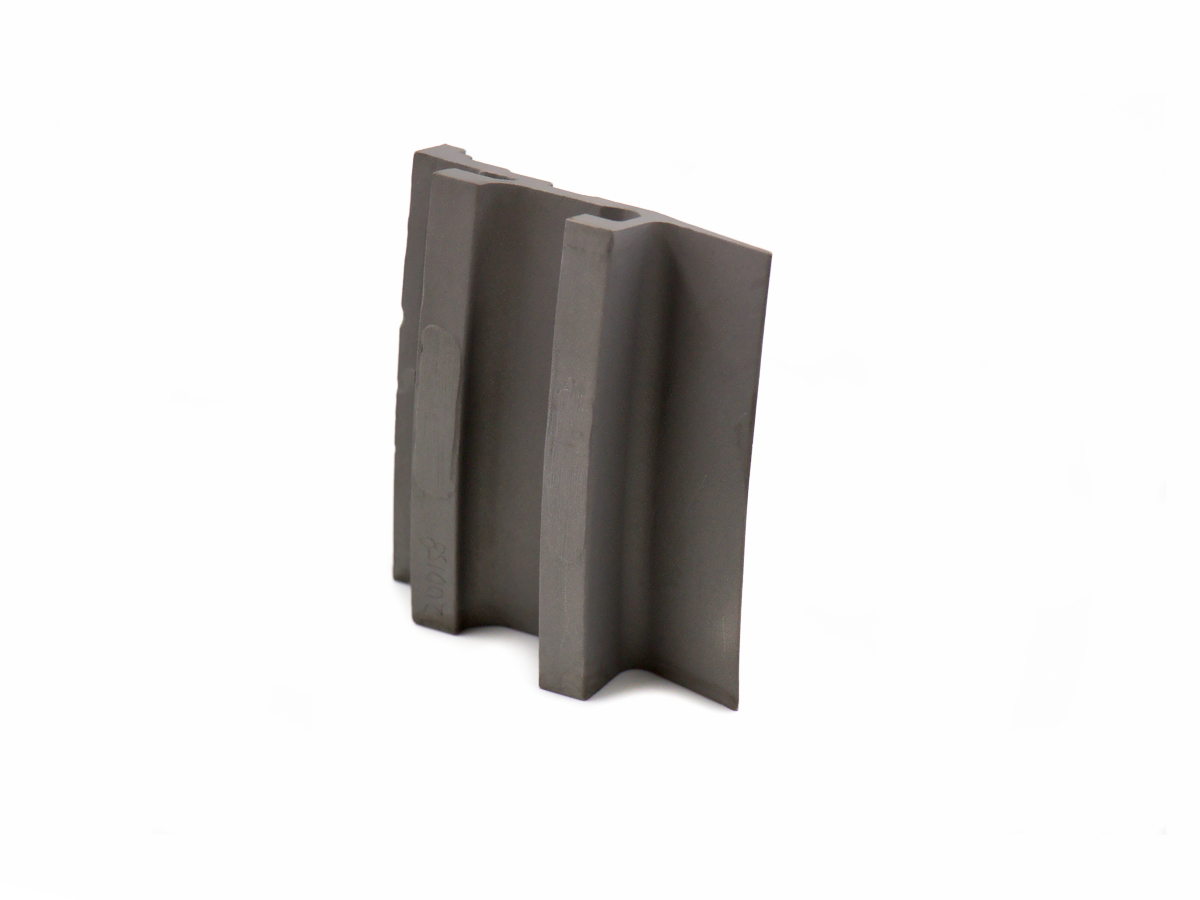

Ultrasonic Additive Manufacturing (UAM) is a groundbreaking solid-state 3D printing technology, capable of producing multi-material superalloy parts without melting. Leveraging ultrasonic vibrations to create metallurgical bonds at temperatures below 150°C, UAM effectively combines superalloys such as Inconel 718, Titanium Alloys, and even copper, delivering superior bond strength, low residual stress, and exceptional mechanical integrity.

Compared to traditional fusion-based methods, UAM reduces thermal distortion by up to 90%, enabling precise integration of electronics, fibers, and sensors directly into metal structures, significantly enhancing performance and functionality.

Applicable Material Matrix

Material | Bond Strength (MPa) | Density (g/cm³) | Electrical Conductivity (% IACS) | Operating Temp. (°C) |

|---|---|---|---|---|

>450 | 8.19 | 2.0 | 700 | |

>500 | 4.43 | 1.0 | 400 | |

>400 | 8.96 | 101 | 250 | |

>350 | 2.70 | 40 | 170 | |

>380 | 7.95 | 2.3 | 600 |

Material Selection Guide

Inconel 718: Preferred for aerospace engine structures and turbine components, providing excellent fatigue resistance and bond strength (>450 MPa) without thermal distortion.

Ti-6Al-4V: Optimal for lightweight structural assemblies and biomedical implants, ensuring high strength-to-weight ratio and minimal residual stress.

Copper C101: Ideal for integrating thermal management features and electrical pathways, offering superb electrical conductivity (101% IACS).

Aluminum 6061: Suitable for lightweight automotive and aerospace structures, achieving excellent machinability and moderate bond strength (>350 MPa).

Stainless Steel 316L: Recommended for corrosion-resistant structures in marine, medical, and chemical processing applications.

Process Performance Matrix

Attribute | UAM Performance |

|---|---|

Dimensional Accuracy | ±0.1 mm |

Layer Thickness | 25–150 μm |

Minimum Feature Size | 0.5 mm |

Surface Roughness | Ra 3–6 μm |

Operating Temperature | Ambient (<150°C) |

Process Selection Guide

Multi-Material Capability: Perfectly suited for combining metals like aluminum, titanium, copper, and superalloys within a single integrated structure.

Minimal Thermal Stress: Reduced residual stresses and distortions, preserving dimensional accuracy and mechanical properties.

Integrated Functionality: Ideal for embedding sensors, electronics, and cooling channels directly into metallic components.

Precision Bonding: Achieves reliable metallurgical bonds (>500 MPa) without melting, ideal for sensitive applications.

Case In-Depth Analysis: UAM Inconel 718 and Copper Hybrid Aerospace Heat Exchanger

An aerospace client required a complex hybrid heat exchanger combining the high-temperature strength of Inconel 718 with the superior thermal conductivity of Copper C101. Utilizing our UAM 3D printing service, we successfully fabricated a fully integrated structure without melting, achieving bond strengths exceeding 450 MPa. The resulting component demonstrated 40% improved thermal management, a 25% weight reduction, and minimized residual stress. Post-processing included precision CNC machining and controlled heat treatment to enhance mechanical and thermal performance.

Industry Applications

Aerospace and Aviation

Integrated cooling structures for aircraft electronics.

Multi-material brackets combining lightweight alloys and superalloys.

Sensor-embedded structural panels for real-time health monitoring.

Automotive

Lightweight multi-material chassis components.

Embedded cooling channels in electric vehicle powertrains.

Advanced battery housings integrating structural and thermal management solutions.

Energy and Power

Complex heat exchangers for renewable energy systems.

Multi-metal components for nuclear reactors with integrated sensor arrays.

Corrosion-resistant structures combining stainless steel and superalloys.

Mainstream 3D Printing Technology Types for Industrial Applications

Selective Laser Melting (SLM): Ideal for high-density metal parts demanding fine resolution and excellent mechanical properties.

Electron Beam Melting (EBM): Preferred for aerospace applications requiring superior fatigue resistance and full density.

Binder Jetting: Efficient for rapid prototyping and scalable production of moderate complexity components.

Direct Metal Laser Sintering (DMLS): Best suited for intricate, high-precision metal parts with complex geometries.

Directed Energy Deposition (DED): Optimal for repairing, modifying, or enhancing existing metal components with precision.

FAQs

What advantages does UAM offer over traditional melting-based 3D printing methods?

Which material combinations are optimal for UAM multi-material integration?

What is the maximum component size achievable with UAM technology?

How does UAM technology ensure strong metallurgical bonding without melting?

What are typical post-processing methods for UAM-produced components?