Which 3D printing technology is best for titanium parts in aerospace applications?

Which 3D Printing Technology Is Best for Titanium Parts in Aerospace Applications?

Optimal Technology: Electron Beam Melting (EBM)

For aerospace-grade titanium components, Electron Beam Melting (EBM) is the most suitable 3D printing technology due to its ability to produce fully dense parts with minimal residual stress and excellent fatigue resistance. EBM operates in a high-vacuum environment at elevated build temperatures (600–700°C), making it ideal for processing titanium alloys prone to cracking during rapid cooling, such as Ti-6Al-4V (Grade 5) and Ti-6Al-4V ELI (Grade 23).

Advantages of EBM for Aerospace Titanium Parts

Stress-free fabrication: The elevated temperature reduces thermal gradients, preventing microcracking and warping.

Excellent fatigue performance: Coarse grain structures improve crack growth resistance in cyclic aerospace loading conditions.

Vacuum environment: Eliminates oxidation, preserving titanium purity—critical for aerospace safety and performance.

High build rates: Suitable for large structural components like brackets, mounts, and airframe elements.

Alternative: Selective Laser Melting (SLM)

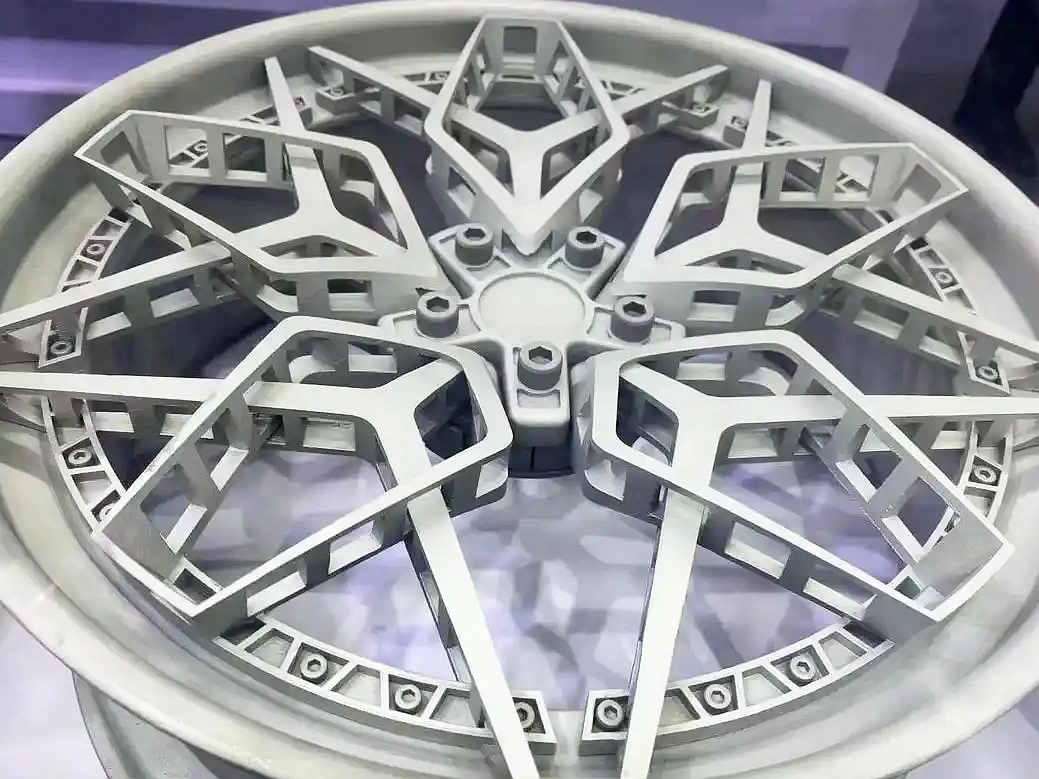

While EBM is preferred for large aerospace structural components, Selective Laser Melting (SLM) is advantageous for high-precision titanium parts requiring finer detail and better surface finish. SLM is ideal for smaller aerospace components such as satellite parts, hydraulic fittings, or fuel system components.

Common SLM-compatible aerospace titanium alloys include:

Ti-6Al-2Sn-4Zr-2Mo – creep resistant for high-temperature service

Ti-5553 – high strength and fatigue life for structural applications

TA15 (Ti-6.5Al-1Mo-1V-2Zr) – excellent weldability and strength-to-weight ratio

Customer-Oriented Solutions and Services

To meet the stringent requirements of aerospace titanium applications, we offer:

3D Printing Technologies:

Learn about our Electron Beam Melting (EBM) and Selective Laser Melting (SLM) services tailored for aerospace-grade titanium production.

Titanium Material Options:

Explore aerospace-qualified titanium alloys, including Ti-6Al-4V, Ti-5553, and TA15, optimized for strength, fatigue resistance, and thermal stability.

Aerospace Solutions and Post-Processing:

Access certified manufacturing support through our aerospace industry services, and enhance components using heat treatment and CNC machining.