What materials are typically used for titanium parts in Selective Laser Melting (SLM)?

What Materials Are Typically Used for Titanium Parts in Selective Laser Melting (SLM)?

Ti-6Al-4V (Grade 5)

Ti-6Al-4V (Grade 5) is the most commonly used titanium alloy in Selective Laser Melting (SLM) due to its excellent balance of strength, corrosion resistance, and weight.

Tensile strength: ~950 MPa

Density: 4.43 g/cm³

Applications: Aerospace structures, turbine components, biomedical implants, and industrial fixtures

Ti-6Al-4V ELI (Grade 23)

Ti-6Al-4V ELI (Grade 23) is a low-oxygen variant of Grade 5 offering improved fracture toughness and biocompatibility.

Tensile strength: ~900 MPa

Fatigue resistance: Superior to standard Grade 5

Applications: Surgical implants, aerospace brackets, and cryogenic components

Ti-6Al-2Sn-4Zr-2Mo

Ti-6Al-2Sn-4Zr-2Mo is used in high-temperature applications requiring enhanced creep resistance.

Operating temperature: Up to 550°C

Applications: Jet engine components, airframe elements, and exhaust systems

Ti-5Al-5V-5Mo-3Cr (Ti-5553)

Ti-5553 is a high-strength beta titanium alloy with excellent fatigue and toughness characteristics.

Tensile strength: >1,200 MPa

Applications: Aerospace structural parts, landing gear, and racing components

Ti-6.5Al-1Mo-1V-2Zr (TA15)

TA15 provides excellent weldability, formability, and strength-to-weight ratio.

Tensile strength: ~1,100 MPa

Applications: Missile components, airframe structures, and lightweight mechanical parts

Customer-Oriented Solutions and Services

To support your SLM titanium part needs, we provide:

3D Printing Technologies:

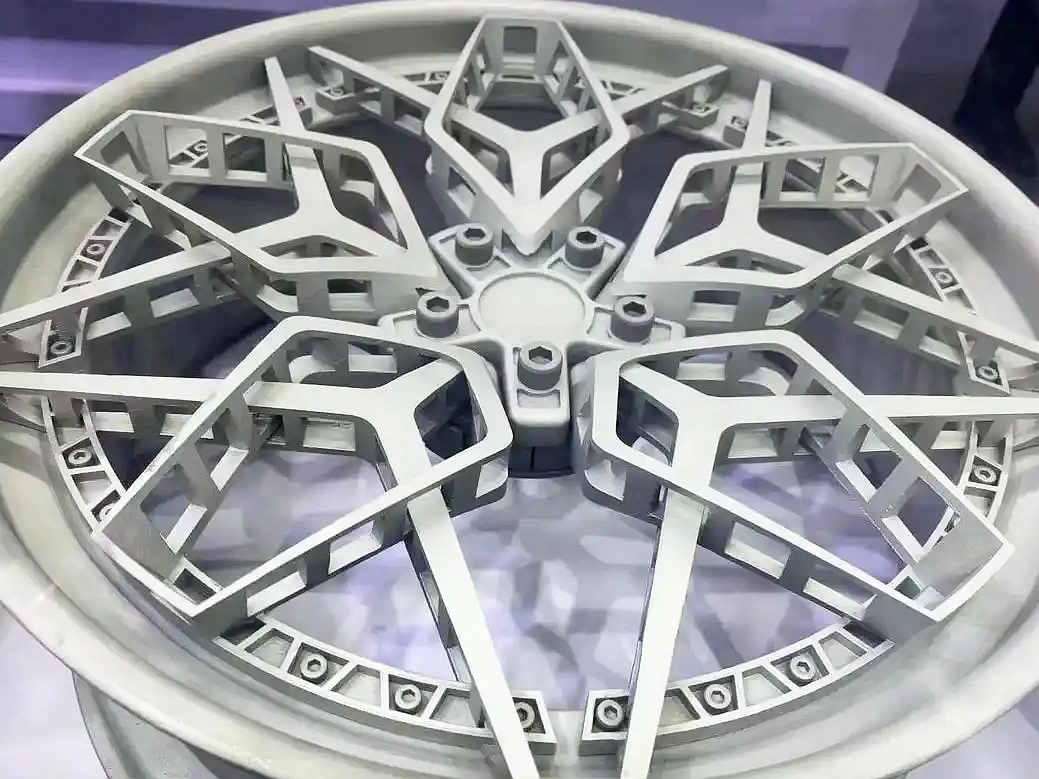

Access our full 3D Printing Service platform offering specialized Titanium 3D Printing, Superalloy 3D Printing, and Stainless Steel 3D Printing solutions for demanding industrial applications.

Titanium Alloy Selection:

Choose from a wide range of titanium alloys including Ti-6Al-4V, Ti-5553, TA15, and high-performance ELI grades tailored for structural, thermal, and biomedical uses.

Post-Processing and Aerospace Support:

Enhance material performance through heat treatment, HIP, and CNC machining, all backed by our aerospace industry solutions.