What is the role of titanium alloys in additive manufacturing for automotive components?

What Is the Role of Titanium Alloys in Additive Manufacturing for Automotive Components?

Lightweight Performance for Structural Efficiency

Titanium alloys are increasingly used in automotive additive manufacturing due to their exceptional strength-to-weight ratio. Alloys such as Ti-6Al-4V (Grade 5) offer a density of 4.43 g/cm³—approximately 40% lighter than steel—while maintaining tensile strengths above 950 MPa. This makes them ideal for producing lightweight structural components such as suspension brackets, drivetrain housings, and performance chassis parts, directly contributing to reduced vehicle mass and improved fuel efficiency.

High-Temperature and Corrosion Resistance

Titanium alloys such as Ti-6Al-2Sn-4Zr-2Mo are employed in automotive components exposed to elevated temperatures, including exhaust system elements and turbocharger housings. These alloys maintain mechanical integrity at temperatures exceeding 500°C while resisting oxidation and corrosive exhaust gases. Additive manufacturing enables precise control over wall thickness and cooling geometries, optimizing thermal management.

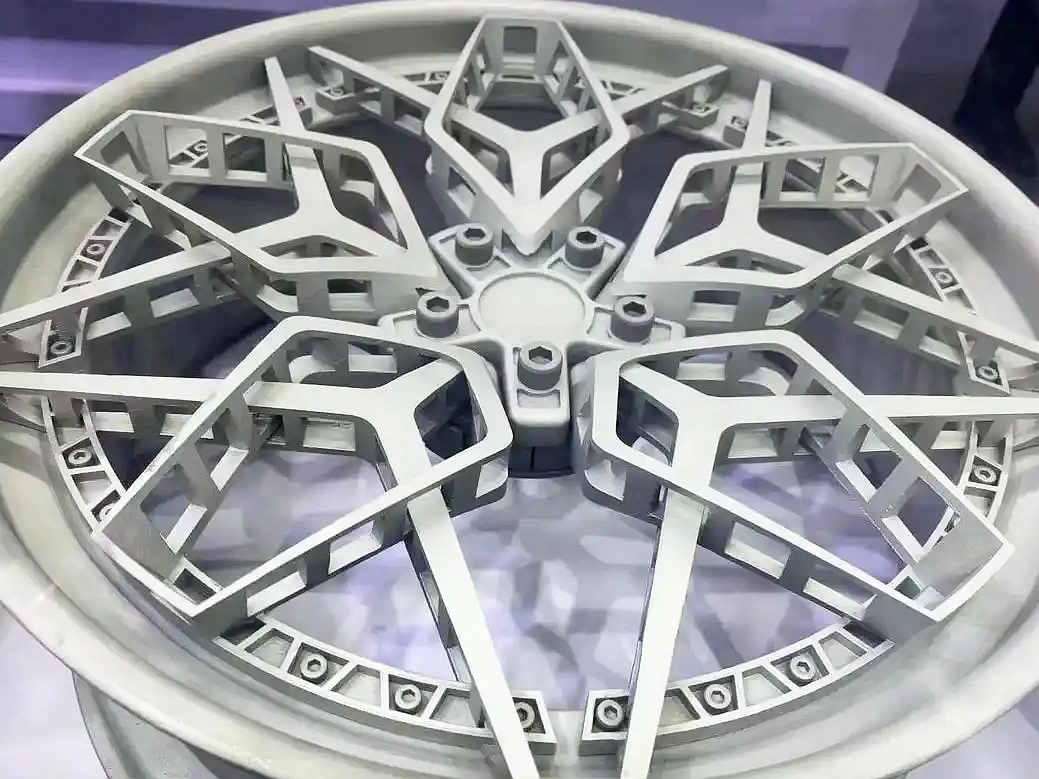

Design Freedom for Functional Optimization

Using technologies like Selective Laser Melting (SLM), titanium alloys can be printed into topology-optimized, lattice-supported designs that are impossible to produce using conventional manufacturing. This enables engineers to create lightweight and structurally robust parts with reduced material consumption and enhanced mechanical performance.

Enhanced Fatigue Resistance and Durability

Titanium’s low modulus of elasticity and high fatigue strength make it suitable for dynamic automotive environments where repeated stress is common. Alloys such as Ti-5553 are particularly valued in motorsport and high-performance vehicle applications for their resistance to crack propagation under cyclic loading.

Customer-Oriented Solutions and Services

To support titanium AM in automotive applications, we offer:

3D Printing Technologies:

Utilize our Titanium 3D Printing solutions powered by SLM for high-performance, precision automotive parts.

Titanium Alloy Selection:

Choose from automotive-grade titanium alloys such as Ti-6Al-4V, Ti-6Al-2Sn-4Zr-2Mo, and Ti-5553 based on your strength, temperature, and fatigue requirements.

Automotive Industry Solutions:

Explore our complete automotive 3D printing capabilities, supported by CNC machining, heat treatment, and surface finishing for end-use part delivery.