How does Electron Beam Melting (EBM) benefit titanium parts for medical implants?

How Does Electron Beam Melting (EBM) Benefit Titanium Parts for Medical Implants?

Biocompatibility and Material Purity

Electron Beam Melting (EBM) is highly effective for manufacturing medical implants from titanium due to its vacuum-based processing environment. Operating in a high-vacuum chamber eliminates contamination from oxygen and nitrogen, preserving the chemical purity and biocompatibility of titanium alloys like Ti-6Al-4V ELI (Grade 23). This alloy is widely used for load-bearing implants such as spinal cages, hip cups, and dental abutments, due to its excellent cytocompatibility, fatigue resistance, and low elastic modulus (~110 GPa).

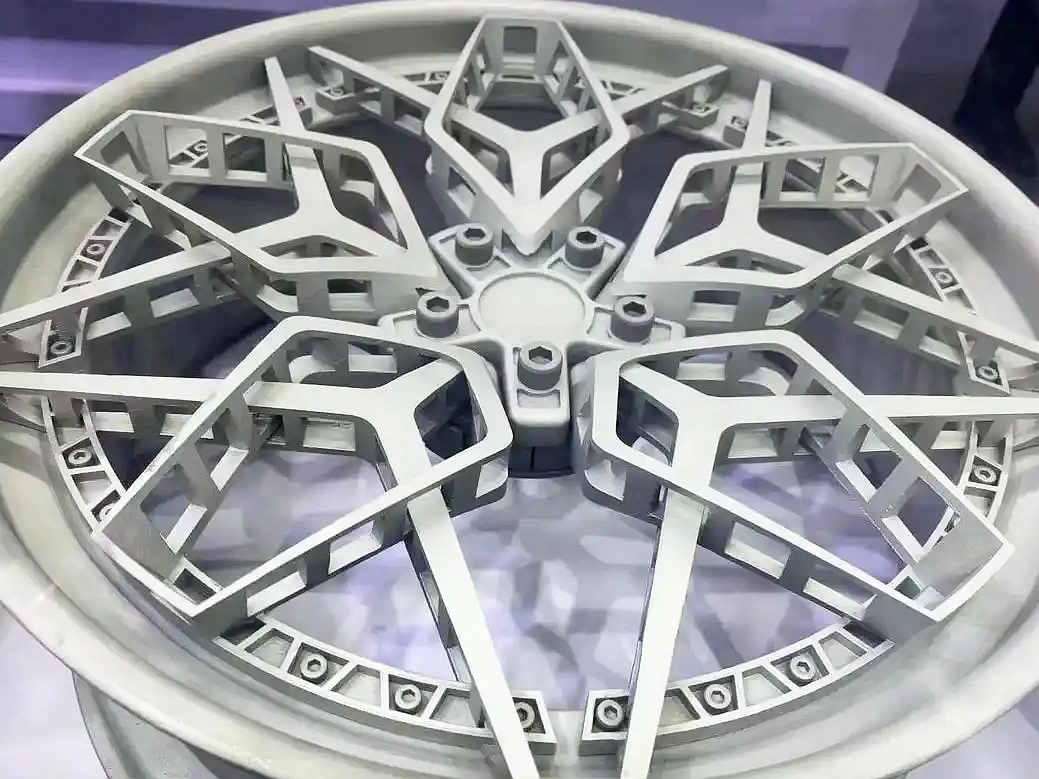

Porous Lattice Structures for Osseointegration

EBM enables the fabrication of highly controlled porous lattice structures that mimic cancellous bone, supporting direct bone in-growth. These architectures, with pore sizes typically ranging from 300–800 µm and porosity between 50–80%, significantly enhance osseointegration, reducing the risk of implant loosening and improving long-term patient outcomes.

Stress-Free Fabrication and Fatigue Resistance

Due to its elevated build temperatures (600–700°C), EBM minimizes residual stresses during the build process. This thermal advantage reduces the need for post-process stress relief and improves the fatigue strength of titanium implants, which is critical for applications in load-bearing anatomical zones.

Complex, Customizable Geometry

EBM supports the production of patient-specific implants with complex geometries and internal channels, which are not feasible with conventional machining. Custom anatomical shapes can be directly derived from CT/MRI scans and fabricated without support structures, further enhancing surgical outcomes and reducing lead time for personalized solutions.

Customer-Oriented Solutions and Services

To support titanium implant development with EBM, we offer:

3D Printing Technologies:

Learn more about Electron Beam Melting (EBM) for biocompatible titanium medical applications via our Titanium 3D Printing services.

Medical-Grade Titanium Alloys:

Explore certified materials such as Ti-6Al-4V ELI and CP-Ti Grades 1–4 for regulated medical use.

Healthcare and Post-Processing Support:

Access our medical and healthcare industry solutions and enhance implant performance with CNC machining and surface treatment options for precision and biointegration.