What types of surface defects or irregularities can HIP address?

What Types of Surface Defects or Irregularities Can HIP Address?

Overview

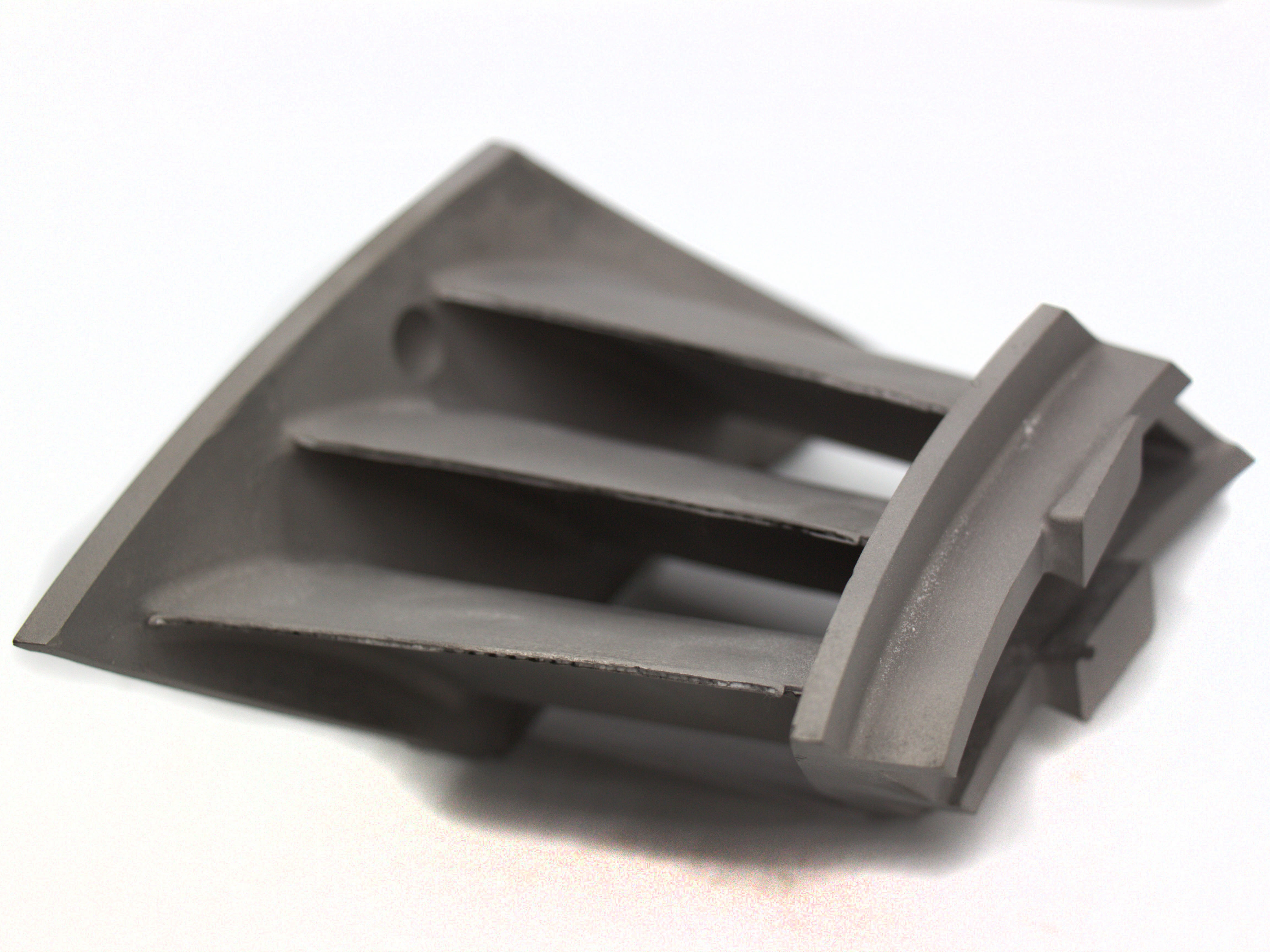

Hot Isostatic Pressing (HIP) is designed to eliminate internal and near-surface porosity in 3D printed metal parts by applying uniform high pressure and temperature. While HIP does not smooth or polish the exterior surface, it is highly effective in addressing specific subsurface defects that would otherwise lead to mechanical failure or degradation of surface integrity after finishing processes.

Surface and Near-Surface Defects Addressed by HIP

1. Subsurface Porosity

HIP is most effective at removing internal and near-surface gas pores, which are typically introduced during the layer-by-layer fusion of metal powders.

HIP compresses these pores and enables atomic diffusion to close them, improving surface continuity after machining or polishing

2. Lack of Fusion Zones

Areas where metal powders fail to melt or bond completely can form weak zones just beneath the surface.

HIP eliminates these by promoting material flow and diffusion bonding under high pressure

Particularly relevant for Inconel 718, Ti-6Al-4V, and Tool Steel H13

3. Microcracks and Interlayer Defects

Microcracks may form between layers or around voids due to thermal gradients and solidification shrinkage.

HIP heals these defects through creep deformation and solid-state diffusion

Enhances fatigue life and prevents crack propagation from the surface inward

4. Entrapped Gas Pockets

Closed internal cavities and blind holes may trap gases during the build process, resulting in localized pressure imbalances.

HIP compresses and homogenizes these zones, eliminating hidden gas pockets

This is especially beneficial in components with enclosed geometries or lattice structures

5. Incomplete Particle Sintering

Some 3D printed surfaces may contain partially fused or loosely bonded particles near the outer shell.

While HIP does not polish these particles off, it improves their cohesion and prevents them from breaking away during use or finishing

Limitations of HIP for Surface Issues

HIP does not remove rough surface texture (Ra 8–12 µm) from powder-bed fusion processes

It does not correct surface waviness, dross, or mechanical damage

Final finishing processes like CNC machining, polishing, or electropolishing are needed for dimensional or aesthetic refinement

Summary: HIP-Addressable Surface-Related Defects

Defect Type | HIP Effectiveness |

|---|---|

Subsurface gas porosity | Completely eliminated |

Lack of fusion zones | Closed and bonded |

Interlayer microcracks | Healed by diffusion |

Gas entrapment in voids | Compressed and homogenized |

Weak surface particle bonding | Improved cohesion |

Applications That Benefit from HIP Surface Consolidation

Pressure-tight parts in SUS316L

Aerospace structures made from Haynes 230

Implants and orthopedic tools in Ti-6Al-4V ELI

Tooling inserts in Tool Steel 1.2709

Recommended Services for Surface Integrity

Neway 3DP supports high-integrity surfaces through:

Hot Isostatic Pressing For defect elimination and improved cohesion beneath the surface

Heat Treatment For stress relief and phase stability following HIP

Surface Treatment Including machining, polishing, or coating for final surface refinement