What types of defects or weaknesses does HIP eliminate to improve part strength?

What Types of Defects or Weaknesses Does HIP Eliminate to Improve Part Strength?

Internal Porosity and Shrinkage Voids

Hot Isostatic Pressing (HIP) is most effective at eliminating internal porosity—voids caused by incomplete melting or gas entrapment during metal and ceramic 3D printing processes like Selective Laser Melting (SLM) and Binder Jetting. These voids act as critical stress concentrators under mechanical loading. By applying pressures up to 200 MPa at elevated temperatures (typically 900–1250°C), HIP compresses and closes internal pores, producing near-full-density structures in materials such as Inconel 718, Ti-6Al-4V, and Alumina.

This densification enhances mechanical properties like tensile strength, elongation, and fatigue resistance, especially in aerospace, medical, and structural components.

Lack of Fusion and Microcracks

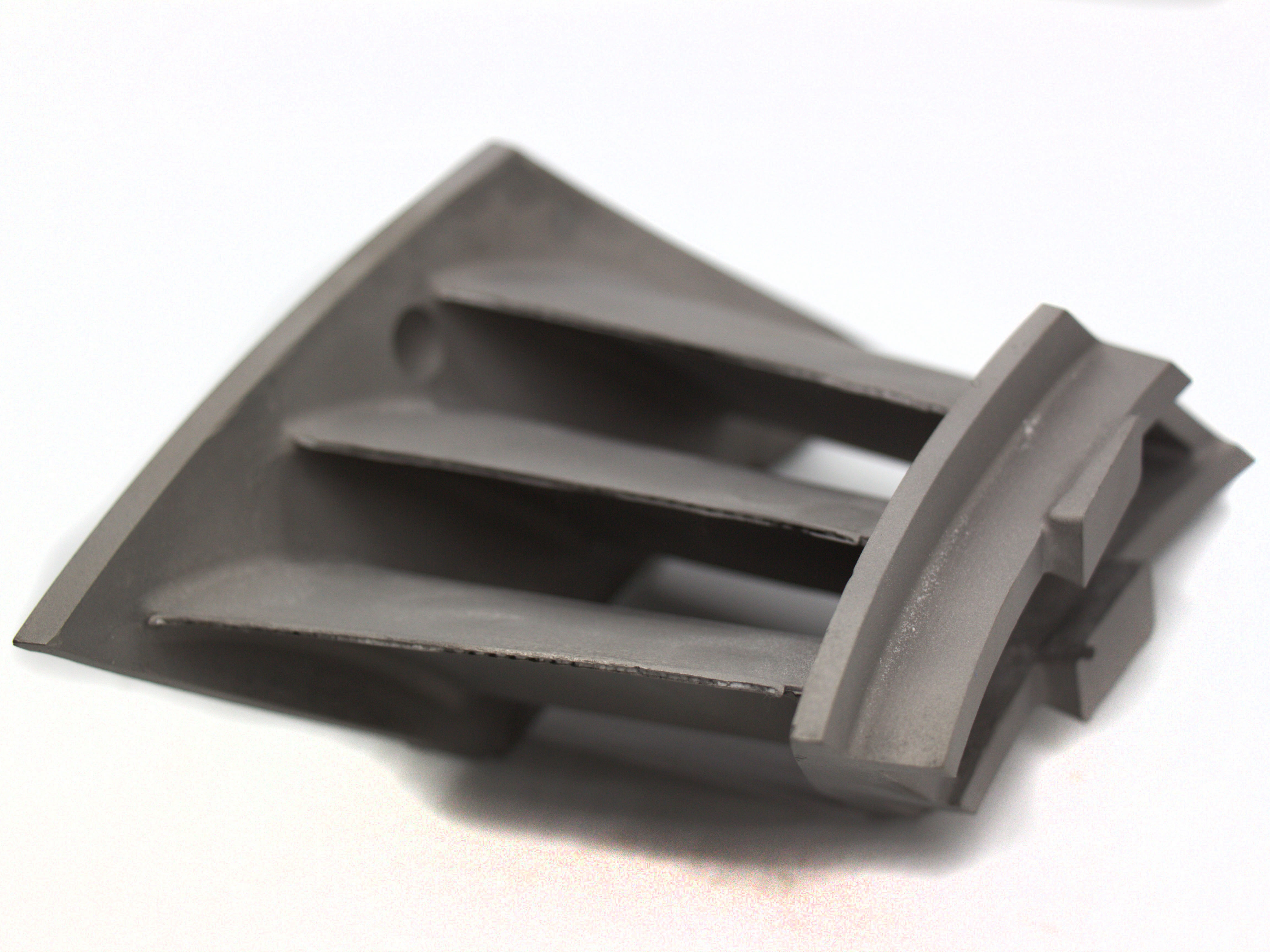

In laser-based printing processes, incomplete fusion between powder layers can form weak interlayer bonds, known as lack-of-fusion defects. These are particularly prevalent in overhanging geometries and large-volume builds. HIP thermally activates diffusion bonding between partially fused grains, permanently sealing interlayer gaps and increasing structural cohesion.

Additionally, microcracks formed due to residual stress or solidification shrinkage are effectively closed and healed during HIP, especially in brittle materials like ceramics or high-strength steels such as Tool Steel M2.

Unmelted Particles and Inclusion Voids

Unmelted powder residues or non-metallic inclusions embedded during the printing process create sites for stress localization and crack nucleation. HIP redistributes these micro-defects within the surrounding matrix through atomic diffusion, reducing discontinuities and homogenizing the material. The result is improved isotropy and impact resistance across the entire volume of the part.

This is especially beneficial in Superalloy 3D Printing applications where internal purity and structural consistency are required under extreme mechanical and thermal stress.

Recommended Services for Defect Elimination and Strength Optimization

Neway provides end-to-end solutions to strengthen critical parts through HIP and complementary services:

Advanced 3D Printing Services:

Titanium 3D Printing: Ideal for aerospace, medical, and lightweight structural applications.

Ceramic 3D Printing: Suitable for precision components requiring zero microcracks and high compressive strength.

Superalloy 3D Printing: Designed for turbine and high-performance parts.

Post-Processing for Defect Resolution:

Hot Isostatic Pressing (HIP): Eliminates porosity, cracks, and interlayer defects.

Heat Treatment: Customizes hardness and grain structure post-HIP for optimal strength.

Dimensional and Surface Optimization:

CNC Machining: Provides tight tolerance finishing post-densification.

Electropolishing: Refines surfaces and removes stress concentrators.