What mechanical property improvements can be expected after HIP processing?

What Mechanical Property Improvements Can Be Expected After HIP Processing?

Overview

Hot Isostatic Pressing (HIP) is one of the most effective post-processing techniques for improving the mechanical properties of 3D printed metal parts. By applying high temperature (typically 900–1250°C) and high isostatic gas pressure (usually 100–200 MPa), HIP eliminates internal porosity, consolidates microstructure, and promotes diffusion bonding. These changes significantly enhance the strength, toughness, fatigue life, and overall reliability of critical components.

Key Mechanical Property Improvements After HIP

1. Increased Density and Strength

HIP eliminates internal voids caused by incomplete fusion or gas entrapment in additive manufacturing. This increases bulk density to over 99.9%, resulting in:

Higher yield strength due to continuous load-bearing cross sections

More consistent ultimate tensile strength across the part volume

Example:

Ti-6Al-4V: yield strength over 900 MPa after HIP

Inconel 718: ultimate tensile strength ~1250 MPa after HIP plus aging

2. Improved Fatigue Resistance

Internal pores act as crack initiation points during cyclic loading. HIP closes these voids, greatly enhancing fatigue life.

HIP-processed parts show 2–4× fatigue strength improvement over as-printed parts

Critical for aerospace brackets, turbine components, and medical implants

Ti-6Al-4V ELI (Grade 23): fatigue limit increases from ~300 MPa to over 600 MPa post-HIP

3. Enhanced Ductility and Fracture Toughness

By eliminating brittle pores and microcracks, HIP improves plastic deformation capacity and resistance to catastrophic failure.

Elongation at break improves by 30–70%

Fracture toughness increases due to improved microstructural continuity

Particularly important for pressure-containing SUS316L and Tool Steel 1.2709

4. Microstructural Uniformity

HIP promotes grain boundary diffusion and phase homogeneity, improving isotropic mechanical behavior and thermal stability.

Eliminates process-induced anisotropy common in layer-based printing

Stabilizes superalloys like Hastelloy X and Haynes 230

Summary of Mechanical Improvements

Property | As-Printed Value | Post-HIP Value |

|---|---|---|

Density | 98–99% | Over 99.9% |

Yield Strength | ~700–850 MPa | Over 900 MPa |

Fatigue Strength | ~300 MPa (typical) | Over 600 MPa |

Elongation at Break | 6–10% | 10–18% |

Fracture Toughness | Moderate | Significantly improved |

Applications Requiring HIP Performance

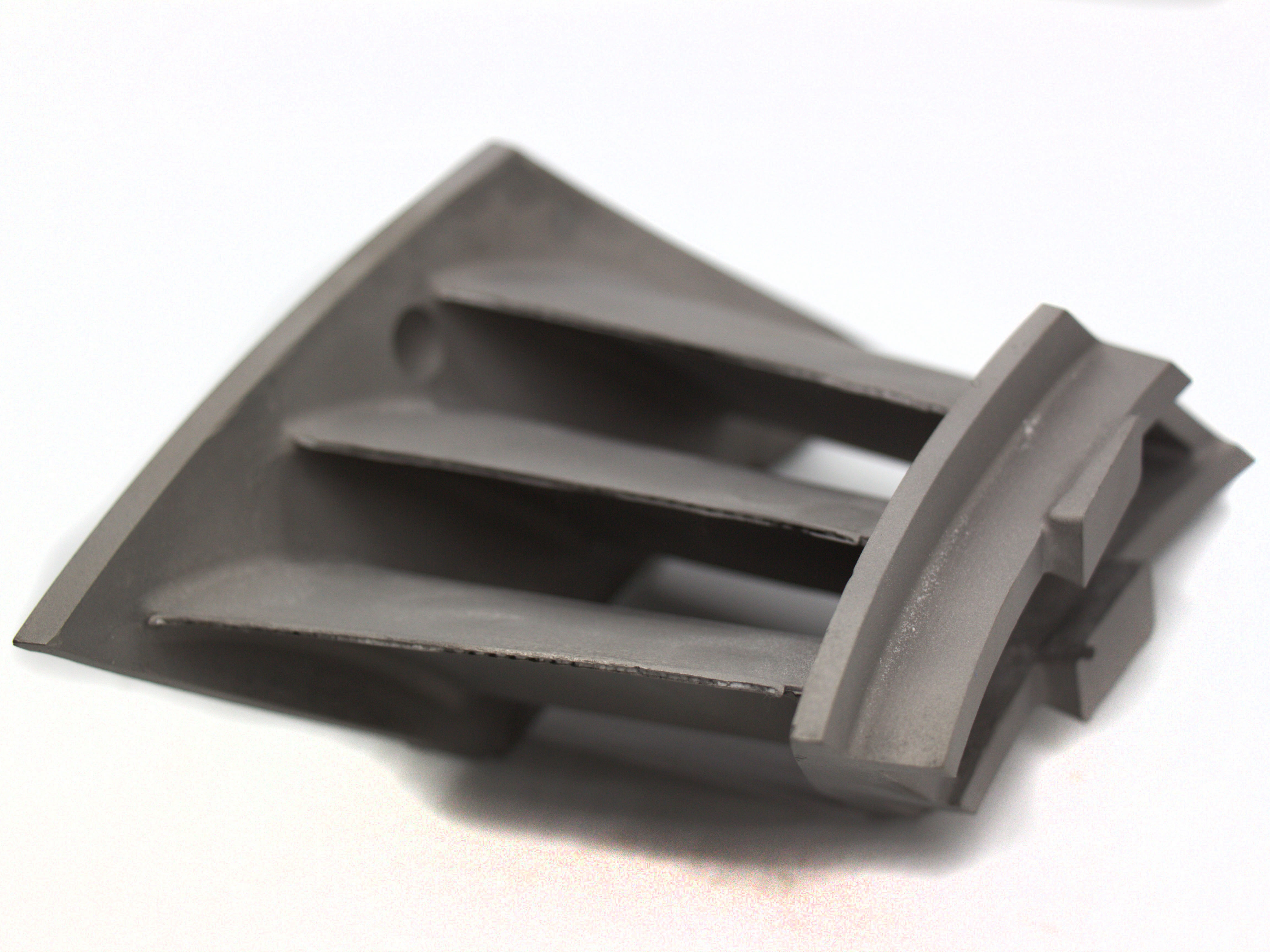

Turbine blades and nozzles in Inconel 625

Orthopedic and dental implants in Ti-6Al-4V ELI

Tooling inserts and dies in Tool Steel H13

High-pressure components in SUS630/17-4 PH

Recommended Services for Maximized Properties

Neway 3DP offers integrated HIP-based workflows:

Hot Isostatic Pressing For porosity elimination, fatigue enhancement, and structural reinforcement

Heat Treatment Follow-up tempering or aging to tailor hardness and phase balance

CNC Machining Final finishing to restore dimensional tolerances post-HIP