Is post-HIP surface treatment required to achieve a final polished finish?

Is Post-HIP Surface Treatment Required to Achieve a Final Polished Finish?

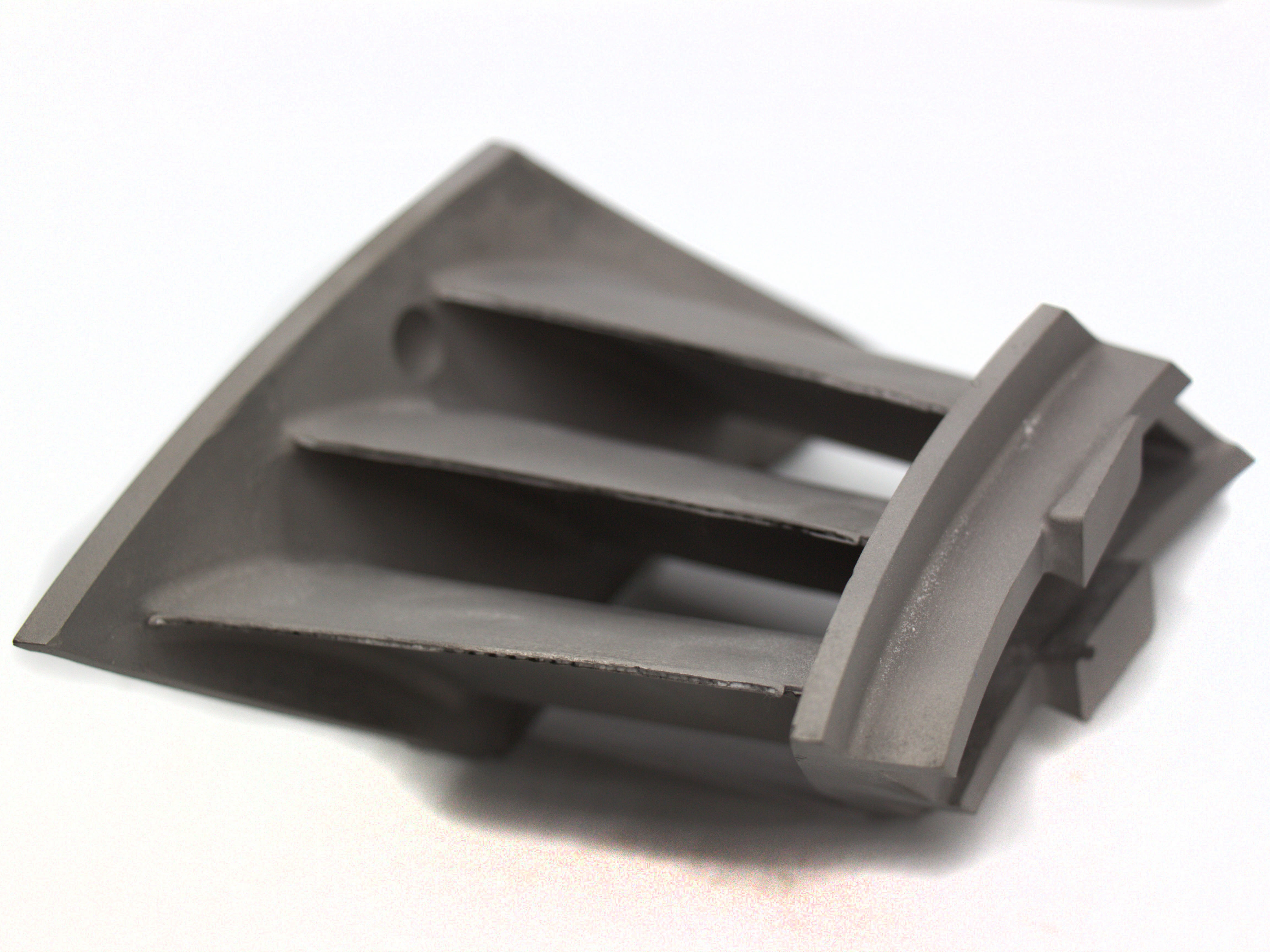

Surface Condition After HIP Processing

After Hot Isostatic Pressing (HIP), 3D printed components typically exhibit improved internal density and mechanical properties, but surface roughness often remains higher than required for polished finishes. HIP treatment significantly reduces internal porosity and enhances structural integrity, yet it doesn't inherently achieve a mirror-like or polished surface condition. Typical surface roughness values post-HIP range from Ra 3–6 µm, depending on material type and printing technology (e.g., Selective Laser Melting (SLM), Electron Beam Melting (EBM)).

Necessity of Additional Surface Treatments

To achieve a final polished finish suitable for high-precision or aesthetically demanding applications, further surface treatments are typically required after HIP. Processes such as CNC machining, electropolishing, or mechanical polishing can significantly reduce surface roughness values to Ra 0.1–0.4 µm, meeting industry standards like ASTM B912 for stainless steel components.

For instance, aerospace turbine blades or medical implants manufactured using Titanium alloys or Superalloys typically require CNC finishing and mechanical polishing post-HIP to achieve the necessary surface integrity and aesthetic standards.

Recommended Surface Finishing Techniques After HIP

Typical surface treatments recommended for final polished finishes after HIP include:

CNC Machining: Offers precise dimensional control and significantly improved surface finish.

Mechanical Polishing: Effectively reduces surface roughness and achieves mirror-like finishes.

Electropolishing: Ideal for corrosion-resistant and hygienic surface finishes, particularly in medical applications.

Recommended Services for Achieving Polished Finishes Post-HIP

Customers seeking optimal polished finishes after HIP processing can take advantage of Neway’s comprehensive post-processing solutions, including:

Precision 3D Printing Services:

Titanium 3D Printing: For demanding biomedical and aerospace applications.

Superalloy 3D Printing: For components needing exceptional mechanical performance and surface quality.

Advanced Post-Processing:

CNC Machining: Provides accurate dimensions and significantly improved surface finishes.

Polishing: Mechanical polishing for mirror-quality surface finishing.

Electropolishing: Ensures smooth, corrosion-resistant surfaces ideal for medical and precision equipment.

Specialized Surface Treatments:

PVD Coating: Enhances aesthetic appeal and wear resistance.

Nitriding: Improves surface hardness for demanding operational environments.