How does HIP improve the mechanical properties of 3D printed parts?

How Does HIP Improve the Mechanical Properties of 3D Printed Parts?

Elimination of Internal Porosity and Defect Healing

Hot Isostatic Pressing (HIP) enhances mechanical properties by eliminating internal porosity, a common byproduct of laser- and electron-beam-based 3D printing processes such as SLM, DMLS, and EBM. By applying isostatic gas pressure (up to 200 MPa) and elevated temperatures (typically 900–1250°C), HIP compresses and bonds internal voids, shrinkage cavities, and unmelted powder inclusions. This results in a fully dense microstructure with near-100% theoretical density, significantly improving fatigue strength and fracture toughness.

In load-critical applications such as turbine blades or medical implants, the elimination of internal defects reduces crack initiation points and enhances structural integrity under cyclic or impact loading.

Improvement in Fatigue, Strength, and Ductility

HIP improves the fatigue life of metallic 3D printed parts by a factor of 2 to 10, depending on material and application. For example, Inconel 718 parts processed with HIP exhibit fatigue strength increases exceeding 30%, and tensile elongation improves from ~10% to over 20%. In Ti-6Al-4V, HIP enhances yield strength and ductility simultaneously—traits critical for aerospace, biomedical, and structural components.

The yield and tensile strength improvements are attributed to pore collapse, grain structure homogenization, and stress relaxation achieved during the HIP cycle.

Applications Requiring Mechanical Optimization

HIP is particularly valuable for parts produced in:

Titanium 3D Printing: Enhancing ductility and fatigue resistance for medical or aerospace parts.

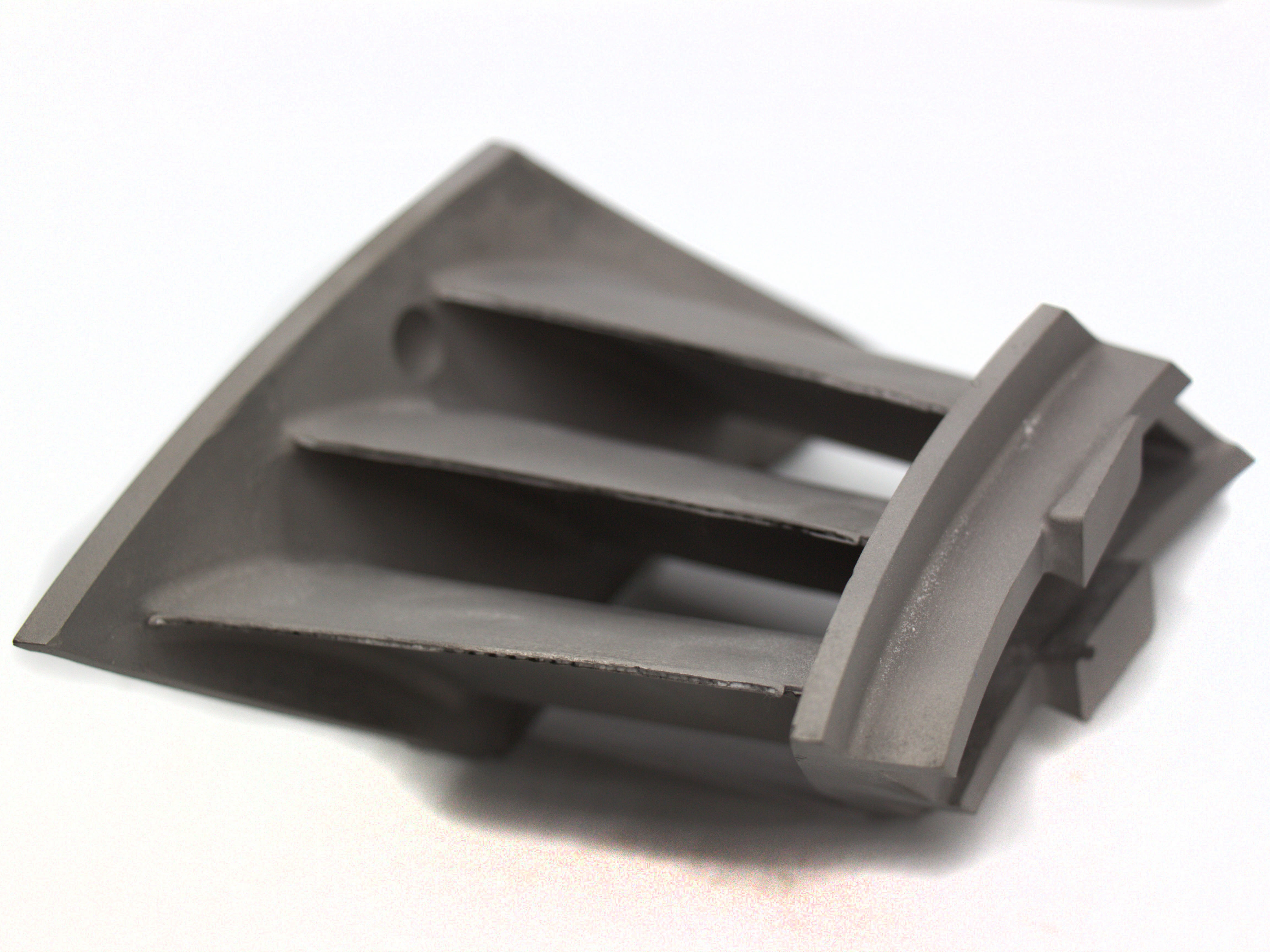

Superalloy 3D Printing: Increasing high-temperature strength in turbine and exhaust components.

Stainless Steel 3D Printing: Improving toughness and corrosion resistance for structural and food-grade applications.

These improvements are essential in aerospace, automotive, energy, and medical sectors, where mechanical reliability and part longevity are mission-critical.

Recommended Services for Mechanical Property Enhancement

To achieve optimal strength, fatigue performance, and ductility in 3D printed components, customers can leverage the following Neway services:

Advanced 3D Printing Options:

Superalloy 3D Printing: For parts exposed to extreme mechanical and thermal stress.

Titanium 3D Printing: For high-performance applications requiring strength-to-weight optimization.

Carbon Steel 3D Printing: Ideal for wear-resistant, impact-tolerant components.

Post-Processing Enhancements:

Hot Isostatic Pressing (HIP): Improves part density, fatigue resistance, and mechanical uniformity.

Heat Treatment: Tailors microstructure and hardness based on application needs.

Finishing and Precision Options:

CNC Machining: Ensures tolerance control and surface finish after HIP consolidation.