Can HIP replace other post-processing methods for achieving structural reliability?

Can HIP Replace Other Post-Processing Methods for Achieving Structural Reliability?

HIP as a Core Densification Process

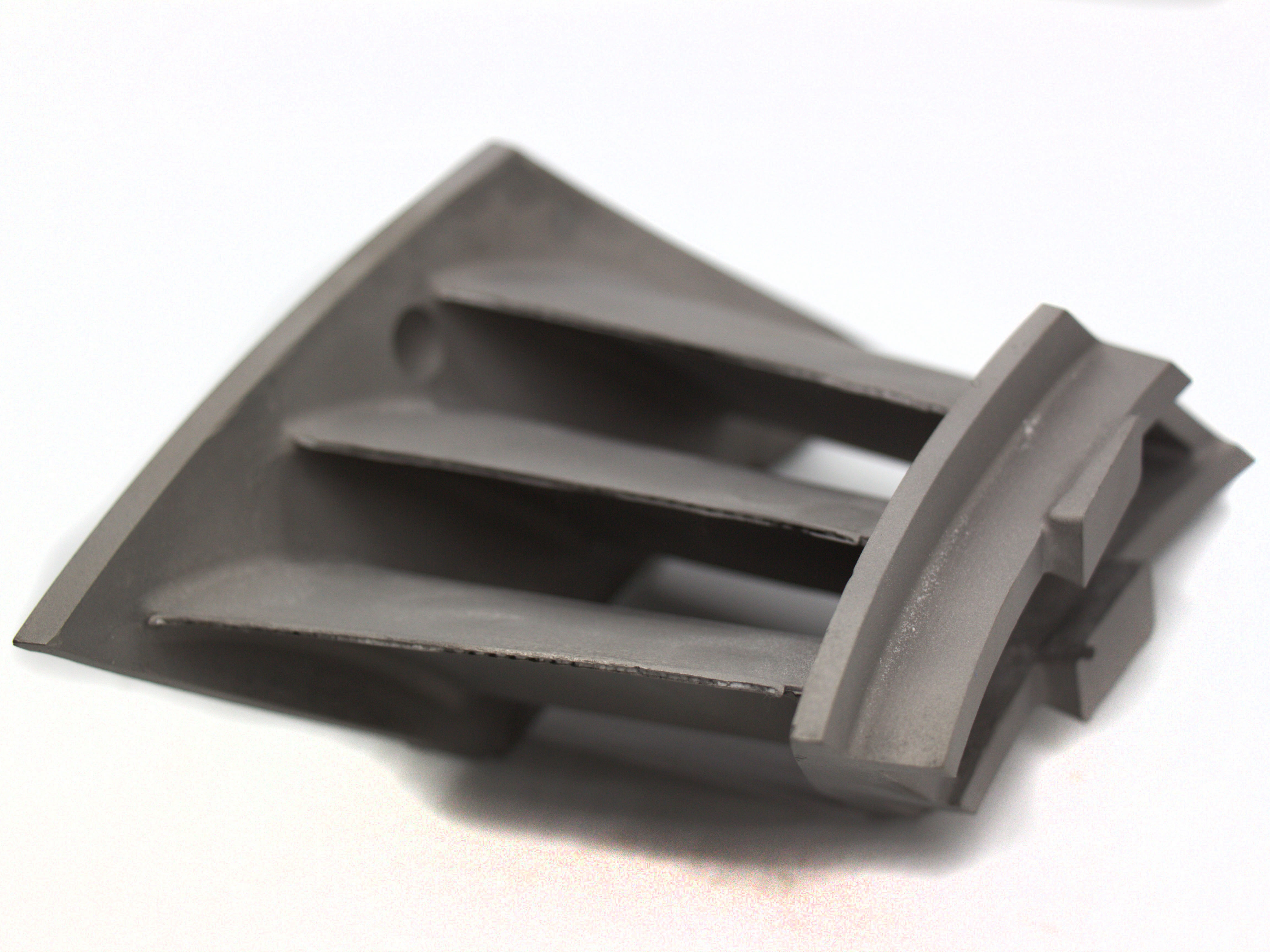

Hot Isostatic Pressing (HIP) is a powerful post-processing method for enhancing structural reliability in metal and ceramic 3D printed components. It eliminates internal porosity, heals microcracks, and promotes grain boundary diffusion under pressures up to 200 MPa and temperatures reaching 1250°C. HIP ensures near-100% theoretical density, making it indispensable for components produced by Powder Bed Fusion and Binder Jetting.

However, HIP addresses internal structural issues—it does not replace other post-processing methods required for surface finishing, tolerance correction, or stress profile optimization.

Complementary Role with Heat Treatment and Machining

HIP enhances bulk mechanical properties such as fatigue strength, ductility, and fracture toughness. Yet, it is typically followed by:

Heat Treatment: Needed to achieve specific hardness or phase transformations in alloys such as Tool Steel H13, Inconel 625, or Ti-6Al-4V.

CNC Machining: Required to meet dimensional tolerances and surface finish requirements, particularly in aerospace or medical components.

Surface Treatments: Such as Electropolishing or PVD Coating, essential for corrosion resistance and wear performance.

When HIP Alone Is Not Sufficient

While HIP can be the most important step in ensuring internal structural reliability, it cannot:

Correct warping or dimensional deviations.

Provide surface finishes required by industries like medical or consumer electronics.

Achieve specific mechanical properties (e.g., martensitic hardness in steel) without follow-up thermal treatment.

Therefore, HIP is not a replacement but a foundational process in a complete post-processing workflow.

Recommended Services for Complete Post-Processing Reliability

Neway provides an integrated set of services that use HIP as a core process while combining other techniques for total structural assurance:

Advanced 3D Printing Materials:

Superalloy 3D Printing: For internal strength and high-temperature reliability.

Titanium 3D Printing: For fatigue-resistant, lightweight aerospace and biomedical parts.

Ceramic 3D Printing: For high-compression, crack-free technical ceramics.

Core Structural Processing:

Hot Isostatic Pressing (HIP): Densifies internal structures and eliminates defects.

Heat Treatment: Refines mechanical profiles for strength or hardness requirements.

Precision and Finish Services:

CNC Machining: Ensures tolerance and surface accuracy.

Electropolishing: Improves fatigue life and corrosion resistance of metal parts.