What are the heat-affected zone and its impact on EDM parts?

What Are the Heat-Affected Zone and Its Impact on EDM Parts?

Definition of Heat-Affected Zone (HAZ) in EDM

In Electrical Discharge Machining (EDM), the heat-affected zone (HAZ) refers to the thin layer of base material that experiences thermal influence during the electrical discharge process but is not completely vaporized or removed. It lies just beneath the recast layer, which is the resolidified material on the surface of the machined part. The HAZ results from the intense but localized heat generated by electrical sparks that cause rapid melting and partial transformation of the metal's microstructure.

Characteristics of the Heat-Affected Zone

Depth: typically ranges from 5 to 50 microns, depending on material, discharge energy, and machining parameters

Microstructure: may exhibit grain coarsening, residual stress, or microcracks due to rapid thermal cycling

Mechanical properties: can become harder and more brittle than the base material due to phase transformation or carbide formation

Impact of HAZ on EDM Parts

Dimensional Accuracy The presence of a hardened HAZ may not directly affect part geometry, but it can influence secondary operations like grinding or polishing due to localized hardness variation.

Surface Integrity If not properly controlled, the HAZ may introduce microcracks or reduce fatigue strength, particularly in parts subject to cyclic or dynamic loading.

Corrosion Resistance HAZ regions may be more prone to corrosion due to altered grain structure or the presence of inclusions, especially in stainless steels or aerospace-grade alloys.

Post-Processing Requirements In high-precision or fatigue-critical applications, the HAZ is typically removed or reduced via:

Thermal stress relief or heat treating to restore base material properties

Customer-Oriented Solutions and Services

To ensure optimal EDM surface quality and part performance, we offer:

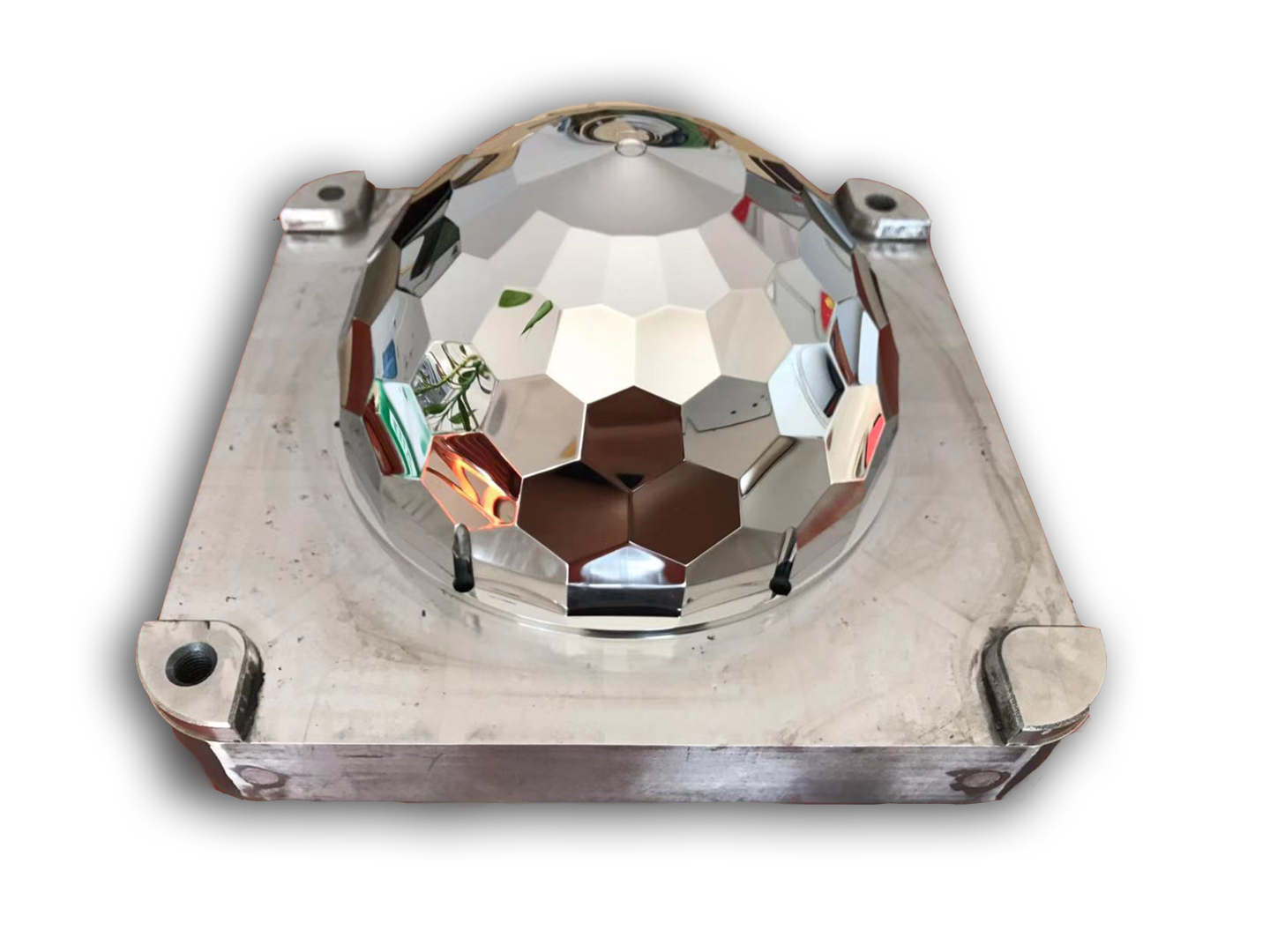

EDM Machining Expertise: Explore our EDM machining services for precision parts with controlled thermal impact.

Post-Processing Solutions Reduce or eliminate HAZ using surface treatment, CNC machining, and heat treatment.

Application-Specific Finishing Support for aerospace, medical, and tool and die parts requiring fatigue-resistance and corrosion performance.