How does EDM maintain accuracy in delicate features?

How Does EDM Maintain Accuracy in Delicate Features?

Non-Contact Material Removal

Electrical Discharge Machining (EDM) maintains exceptional accuracy in delicate features by removing material through spark erosion rather than mechanical cutting. Since there is no physical contact between the electrode and the workpiece, there are no cutting forces that could deflect thin walls, deform microstructures, or damage small features. This allows for consistent machining of tight-tolerance geometries such as micro-holes, fine grooves, and sharp internal corners.

Controlled Spark Energy and Discharge Parameters

EDM machines precisely regulate the discharge current, pulse duration, and spark frequency. In fine-detail operations, these parameters are minimized to control material removal at the micron level. The result is low thermal penetration, limited material recast, and high dimensional repeatability, even on complex or miniature components.

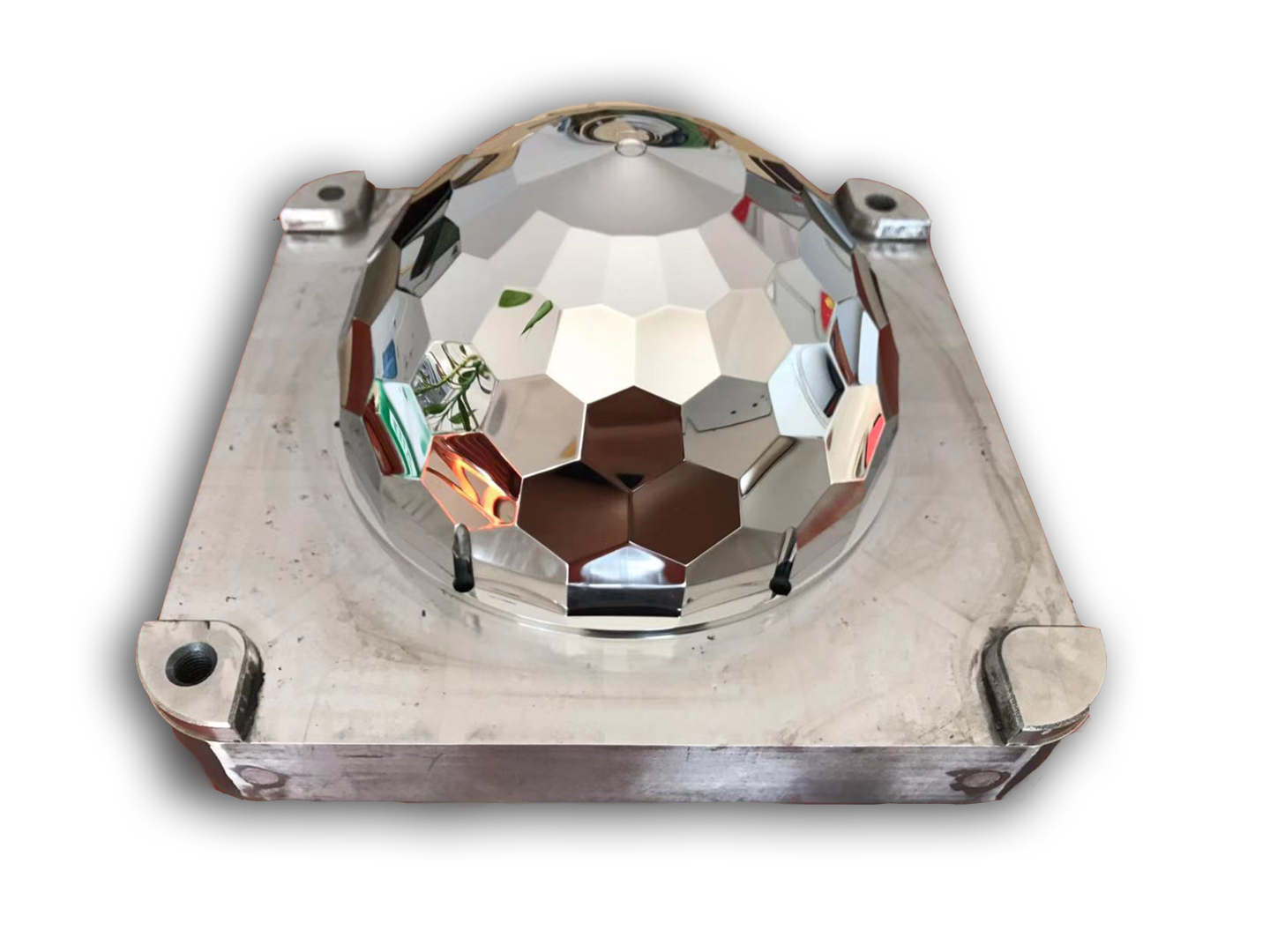

Precision Electrode Shaping

The electrode itself is custom-shaped to match the desired feature, allowing it to replicate intricate geometries with high fidelity. Modern EDM processes use electrodes manufactured via CNC, ensuring perfect control over the feature profile and minimal dimensional deviation during discharge.

Stable Dielectric and Adaptive Flushing

The dielectric fluid not only insulates the spark gap but also helps flush away debris that can interfere with fine feature accuracy. Adaptive flushing techniques ensure constant gap conditions and avoid secondary discharges, which is crucial when working with micro features or narrow slots.

Minimal Tool Wear Compensation

In die-sinking EDM, tool wear is a factor in precision. However, advanced EDM systems can automatically compensate for tool wear, adjusting electrode paths in real time to maintain feature integrity over long production runs.

Customer-Oriented Solutions and Services

We provide high-accuracy EDM capabilities for micro-feature applications:

EDM Machining Technologies Explore our EDM machining services for precise, non-contact shaping of fine features in metal components.

High-Performance Materials Work with tool steels, titanium alloys, and superalloys commonly used in delicate and high-strength part production.

Application-Specific Finishing Support for medical, aerospace, and tooling parts requiring micron-level precision, backed by surface finishing and CNC machining.