How does EDM machining prevent material deformation?

How Does EDM Machining Prevent Material Deformation?

No Mechanical Force During Machining

Electrical Discharge Machining (EDM) removes material through controlled electrical sparks rather than physical contact. Unlike conventional cutting or milling, EDM uses a non-contact process where the tool (electrode) and workpiece never touch. This eliminates mechanical cutting forces, significantly reducing the risk of deflection, warping, or vibration-induced stress on thin-walled, small, or delicate components.

Low Residual Stress and Thermal Control

Although EDM is a thermal process, it uses localized, pulsed discharges with carefully controlled spark energy. The rapid cooling of the material between pulses minimizes the heat-affected zone (HAZ), reducing thermal gradients that can lead to distortion. Modern EDM systems also use dielectric fluids to flush away debris and dissipate heat efficiently, further preventing structural changes or deformation in precision-critical parts.

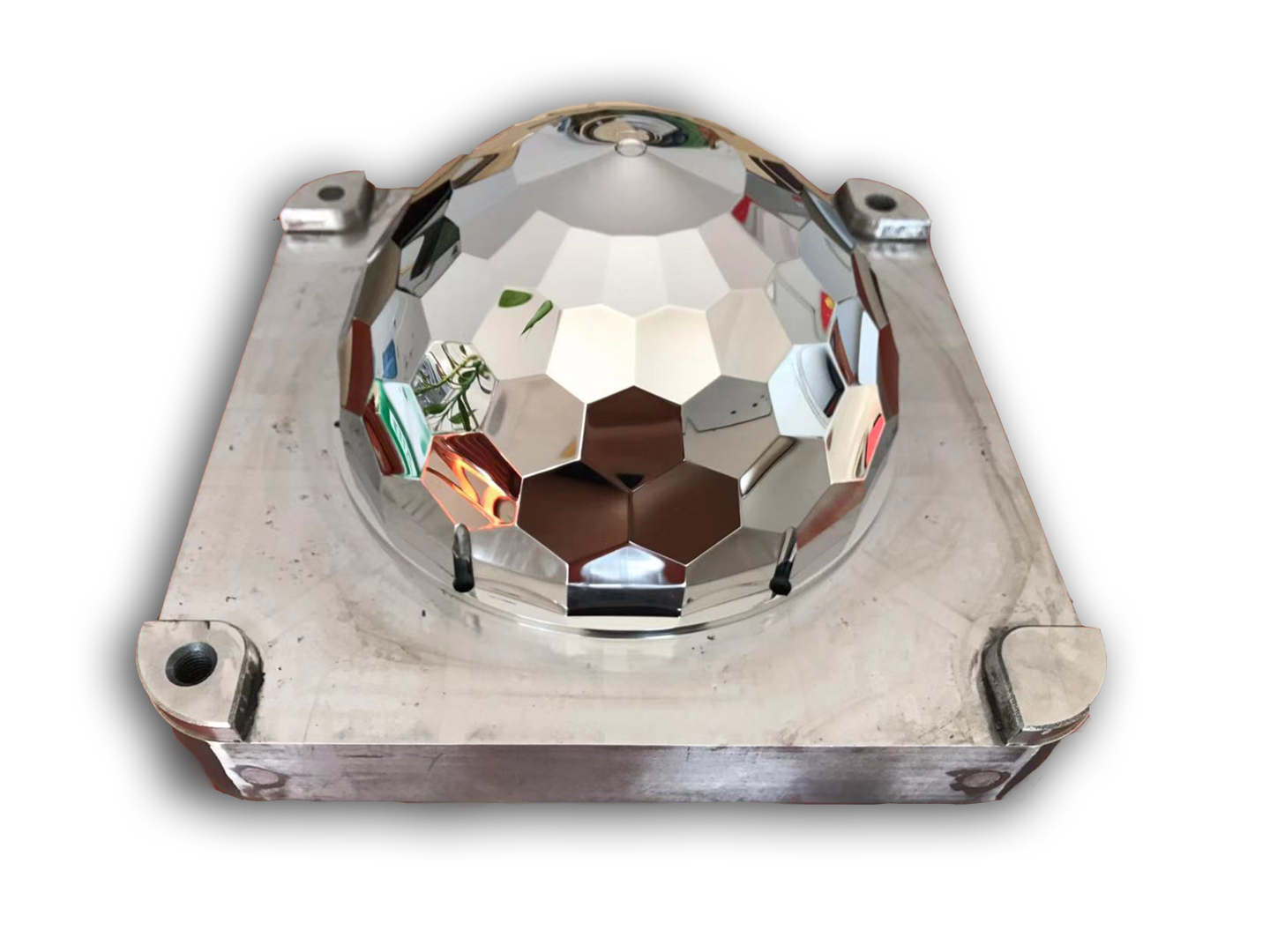

Ideal for Hardened Materials and Complex Geometries

EDM excels at machining hard metals and alloys that are prone to deformation under mechanical loading, such as tool steels, titanium, and Inconel. It allows for the creation of fine features, sharp internal corners, and deep cavities without inducing bending or material fatigue, making it ideal for aerospace, mold-making, and medical tooling applications.

Customer-Oriented Solutions and Services

To support deformation-free part production, we offer:

EDM Machining Technologies:

Explore our EDM machining services for high-precision, non-distorting processes.

High-Performance Materials:

Machining support for tool steels, titanium alloys, and superalloys that are difficult to process mechanically.

Industry Applications:

Discover solutions for aerospace, medical, and tool and die making, supported by CNC machining and surface treatment.