How does EDM machining improve the surface finish of 3D printed parts?

How EDM Machining Improves the Surface Finish of 3D Printed Parts

Surface Challenges in 3D Printed Metal Parts

Additive manufacturing processes like Selective Laser Melting (SLM), Electron Beam Melting (EBM), and Direct Metal Laser Sintering (DMLS) often leave parts with high surface roughness (Ra 8–12 µm) due to powder sintering, stair-stepping, and thermal solidification patterns. These surface irregularities negatively affect fatigue life, sealing performance, and aesthetics.

EDM as a Non-Contact Surface Finishing Method

Electrical Discharge Machining (EDM) offers a highly effective post-processing solution for improving the surface finish of 3D printed metal components. By generating controlled electrical discharges in a dielectric fluid, EDM selectively erodes surface peaks without mechanical force. This results in smooth, uniform finishes down to Ra < 0.2 µm—ideal for aerospace, medical, and high-precision tooling applications.

Advantages of EDM for Additive Components

Uniform Finish on Complex Geometries

EDM reaches deep cavities, thin walls, and internal channels that are often inaccessible to traditional polishing or abrasive finishing. This makes it highly effective for internal cooling passages in turbine blades made from Inconel 718 or thin-walled orthopedic implants in Ti-6Al-4V ELI (Grade 23).

Thermal Stability Without Deformation

Because EDM applies no cutting force, it avoids mechanical distortion—particularly important for materials like Tool Steel H13, Hastelloy C-276, or SUS316L. It preserves dimensional accuracy while refining surface features.

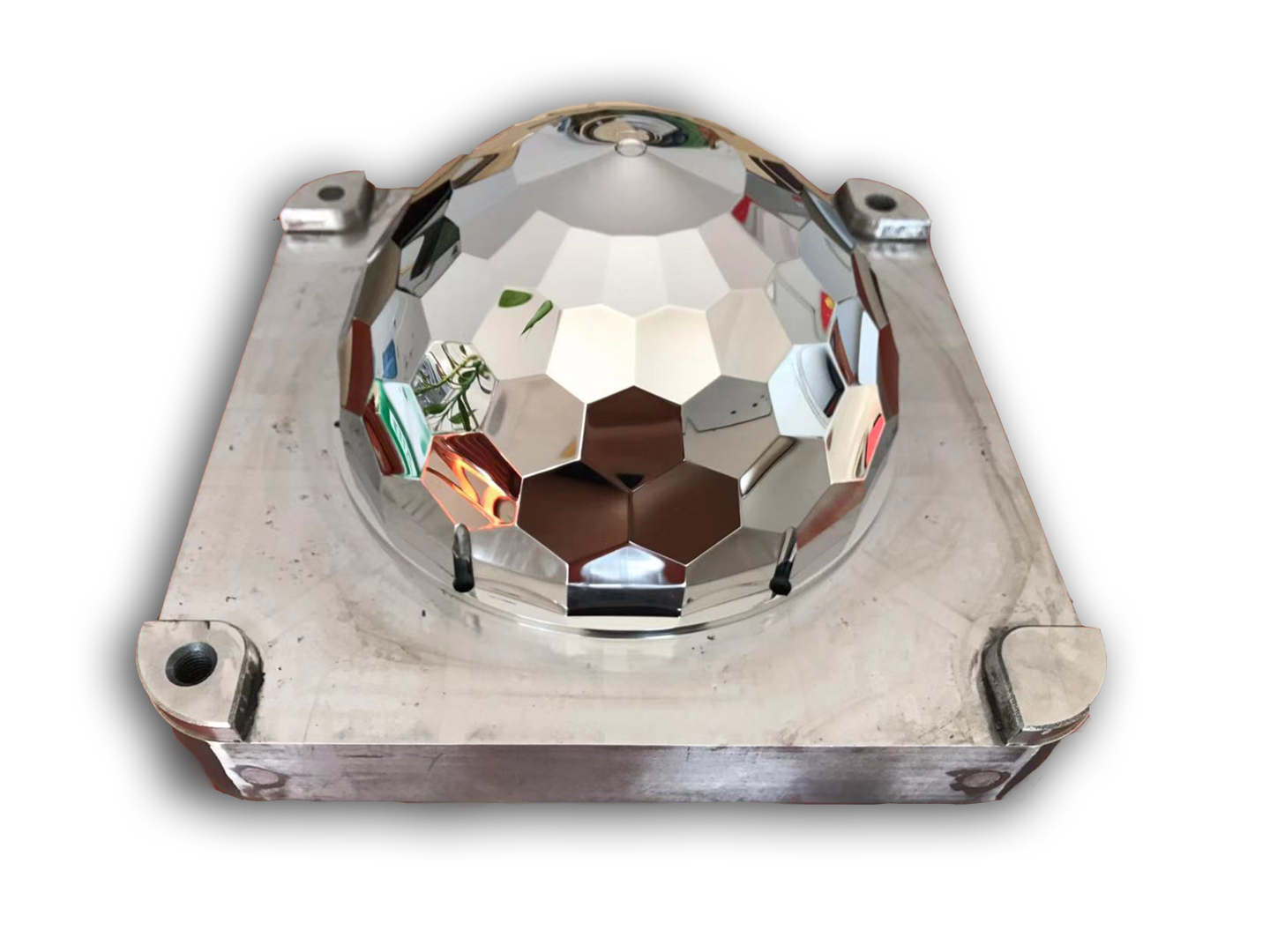

Mirror Finish Capability

Finishing parameters can be tuned to achieve high-gloss mirror surfaces, particularly on precision parts like injection mold inserts, surgical tools, and sealing interfaces. This significantly reduces the need for secondary polishing or grinding.

Typical Surface Finish Results After EDM

Material | 3D Printed Surface (Ra µm) | Post-EDM Finish (Ra µm) |

|---|---|---|

Ti-6Al-4V | 8–10 | 0.2–0.4 |

Inconel 718 | 10–12 | 0.2–0.3 |

SUS316L | 9–11 | 0.1–0.3 |

Tool Steel H13 | 8–10 | 0.2–0.4 |

Recommended Services for Enhanced Surface Quality

Neway 3DP provides complete finishing workflows for additive parts:

EDM Machining Precision finishing for internal and external geometries with minimal dimensional impact.

Electropolishing Further improves smoothness and corrosion resistance, ideal for medical and aerospace parts.

PVD Coating Adds durability and aesthetic appeal while preserving the improved surface texture.

Our combined capabilities deliver functional and cosmetic finishing results that meet industry standards for high-performance 3D printed components.