Can EDM be used to machine internal geometries in 3D printed parts?

Can EDM Be Used to Machine Internal Geometries in 3D Printed Parts?

EDM’s Advantage in Internal Feature Machining

Yes, Electrical Discharge Machining (EDM) is one of the few precision machining methods capable of accurately refining internal geometries in 3D printed parts. Unlike traditional subtractive processes, EDM operates without physical contact, using electrical discharges through a dielectric fluid to erode conductive materials. This enables it to reach internal channels, deep cavities, and narrow slots that are otherwise inaccessible, especially in metal components fabricated via Selective Laser Melting (SLM) or Electron Beam Melting (EBM).

Key Capabilities of EDM for Internal Machining

Deep Hole and Channel Finishing

EDM is ideal for refining internal passageways in heat exchangers, hydraulic manifolds, or turbine components made from Inconel 625, Hastelloy X, or Ti-6Al-4V. It can access channels with aspect ratios exceeding 20:1 while maintaining tolerances below ±0.005 mm.

Burr-Free and Stress-Free Finishing

Because EDM doesn’t apply cutting forces, it avoids deformation or tool-induced burrs in confined geometries—an advantage for parts with internal features like cooling ports, fuel lines, or sensor conduits. This is especially valuable for high-performance parts in aerospace and medical sectors.

Fine Detail and High Aspect Ratio Features

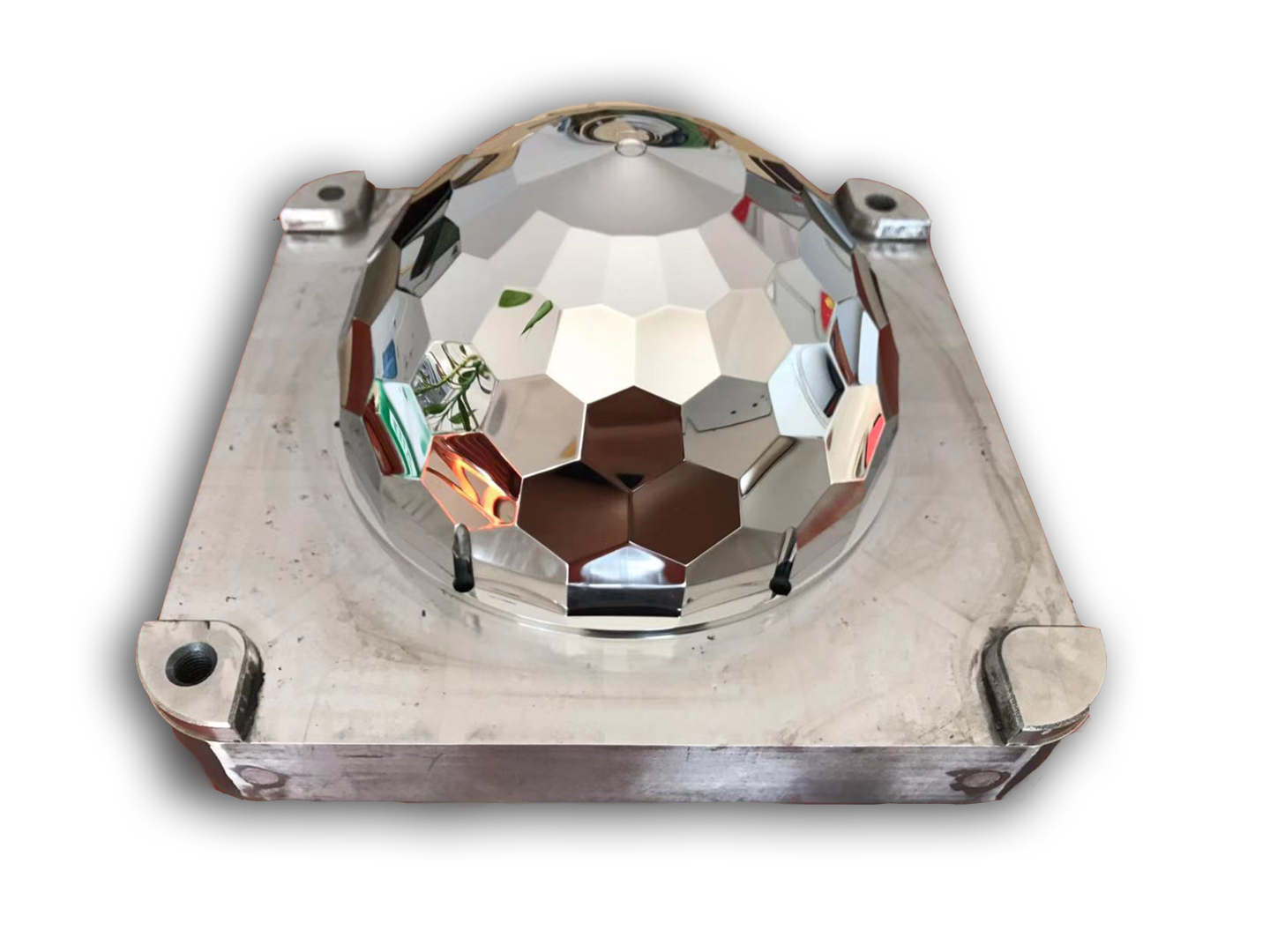

Micro-EDM enables machining of holes as small as 0.1 mm in diameter with ultra-fine depth control. Applications include surgical fluid delivery systems, injector ports, and conformal cooling channels in molds made from Tool Steel 1.2709 or SUS316L.

Examples of Internal Geometry Applications

Turbine blades with internal cooling circuits made from Haynes 230

Spinal cages and surgical implants with lattice or porous structures in Ti-6Al-4V ELI (Grade 23)

Injection molds with conformal cooling channels in Tool Steel H13

Recommended Services for Internal Geometry Refinement

To ensure internal features meet functional and dimensional requirements, we recommend:

EDM Machining Precision erosion of enclosed or high-aspect-ratio features in hard metals.

Heat Treatment Stabilizes material properties and dimensional accuracy after EDM refinement.

Electropolishing Enhances flow and corrosion resistance in internal channels, particularly in medical and aerospace components.

Neway 3DP combines additive and subtractive processes to deliver high-functioning, internally complex components with verified tolerances.