¿Cómo se comparan las resistencias del aluminio impreso en 3D y del aluminio fundido en arena?

Tabla de contenidos

Mechanical Property Comparison Between Manufacturing Methods

Tensile and Yield Strength Performance

As-Manufactured Strength Properties

Post-Processing Strength Enhancement

Fatigue and Durability Characteristics

Crack Initiation Resistance

Surface-Sensitive Performance

Application-Specific Strength Considerations

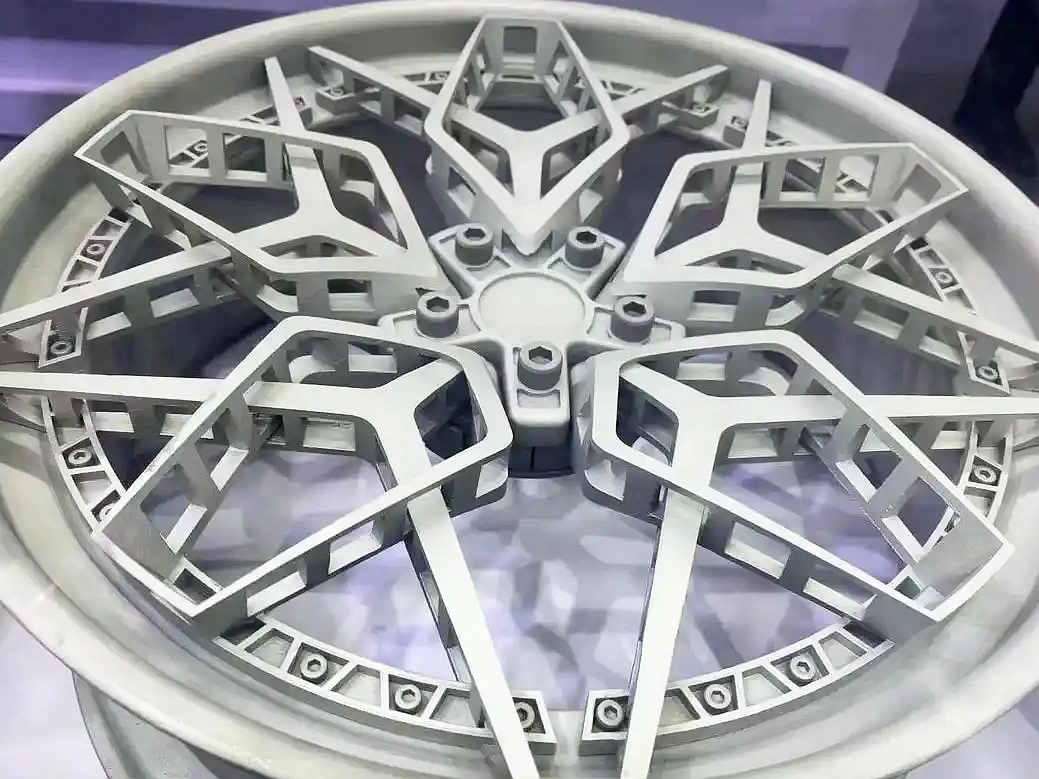

Design-Driven Performance Advantages

Economic and Production Considerations

Español / ES

Título

¿Cómo se comparan las resistencias del aluminio impreso en 3D y del aluminio fundido en arena?

Descripción

Comparación técnica de propiedades de resistencia entre componentes de aluminio impresos en 3D y fundidos en arena, analizando tracción, fatiga y ventajas según aplicación.

Palabras clave

resistencia aluminio 3D, comparación aluminio fundido en arena, propiedades mecánicas AM, comparación de resistencia a tracción, rendimiento a la fatiga, propiedades de aleaciones de aluminio, selección del método de fabricación, relación resistencia-peso

Related Blogs

Suscríbase para recibir consejos de diseño y fabricación de expertos en su bandeja de entrada.

Compartir esta publicación: