Inconel 718 Maximum Service Temperature: Custom 3D Printed High-Temp Metal Parts

Introduction

Inconel 718 is a high-strength, corrosion-resistant nickel-based superalloy widely used in aerospace, energy, and automotive industries. Its superior mechanical properties are retained at elevated temperatures, making it a top choice for components operating in extreme environments. According to AMS 5662 and ASTM B637 specifications, Inconel 718 offers tensile strength exceeding 1,200 MPa and excellent creep resistance up to 650–700°C.

The maximum service temperature of Inconel 718 is a critical parameter when designing parts for high-temperature applications. Conventional manufacturing limits design freedom and drives up costs for complex geometries. Superalloy 3D Printing now enables engineers to create optimized, lightweight structures with intricate cooling channels that outperform traditional cast or machined components.

Advancements in Inconel 718 additive manufacturing, combined with precise heat treatment and surface engineering, further extend the alloy’s thermal limits. This article explores Inconel 718’s service temperature capabilities, the factors influencing high-temperature performance in 3D printed parts, and key design considerations for custom components operating under extreme thermal loads.

Understanding Inconel 718: Composition, Properties and Service Limits

Chemical Composition and Alloy Structure

Inconel 718 is a precipitation-hardened nickel-based superalloy known for its excellent high-temperature strength and corrosion resistance. The typical chemical composition is defined by ASTM B637 and AMS 5662 standards and includes:

Nickel (Ni): 50–55%

Chromium (Cr): 17–21%

Iron (Fe): Balance

Niobium (Nb) + Tantalum (Ta): 4.75–5.50%

Molybdenum (Mo): 2.80–3.30%

Titanium (Ti): 0.65–1.15%

Aluminum (Al): 0.20–0.80%

The alloy’s exceptional mechanical properties derive from a two-phase strengthening mechanism:

Gamma prime (γ'): Ni₃(Al,Ti)

Gamma double prime (γ''): Ni₃Nb

These phases precipitate during controlled heat treatment, significantly enhancing creep resistance, fatigue life, and tensile strength at elevated temperatures.

Mechanical Properties at Elevated Temperatures

Inconel 718 maintains superior mechanical performance across a wide temperature range. According to data from AMS 5663 and OEM aerospace standards:

Property | Room Temp (20°C) | 650°C | 700°C |

|---|---|---|---|

Ultimate Tensile Strength | ~1,280 MPa | ~1,020 MPa | ~870 MPa |

Yield Strength (0.2% PS) | ~1,030 MPa | ~860 MPa | ~700 MPa |

Creep Rupture Life (100 MPa) | >5000 hrs @ 650°C | ~2000 hrs @ 700°C | N/A |

Notably, Inconel 718 exhibits minimal phase instability and maintains excellent fatigue life even after prolonged thermal exposure, making it ideal for cyclic high-temperature environments such as gas turbines and aircraft engines.

Maximum Service Temperature Limitations

The maximum continuous service temperature of conventionally processed Inconel 718 is typically rated at ~650–700°C for long-term applications, per ASME Section VIII and NACE MR0175 recommendations.

For short-term peak exposure, optimized 3D printed and heat-treated components can tolerate transient temperatures of up to 750°C, provided suitable post-processing (HIP, stress relief, aging) and surface protection are applied.

However, prolonged exposure above 700°C risks gamma double prime (γ'') phase instability and grain boundary embrittlement, requiring careful design and life assessment for critical aerospace or energy parts.

Why Use 3D Printing for Inconel 718 High-Temperature Parts?

The integration of 3D printing technologies for Inconel 718 has revolutionized the way engineers approach high-temperature component design. Compared to conventional casting or subtractive manufacturing, additive manufacturing (AM) offers unparalleled design flexibility, cost efficiency, and material performance enhancements.

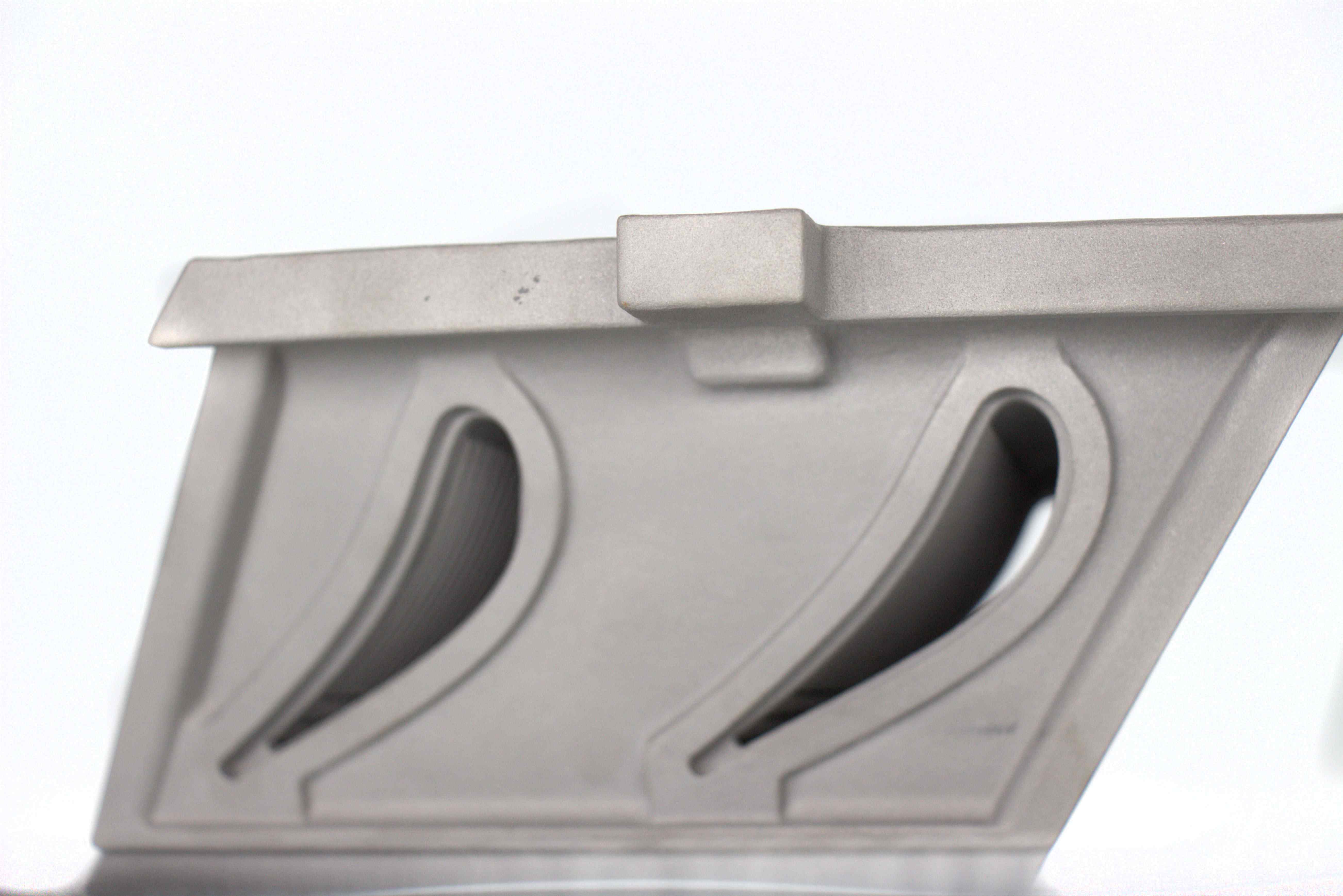

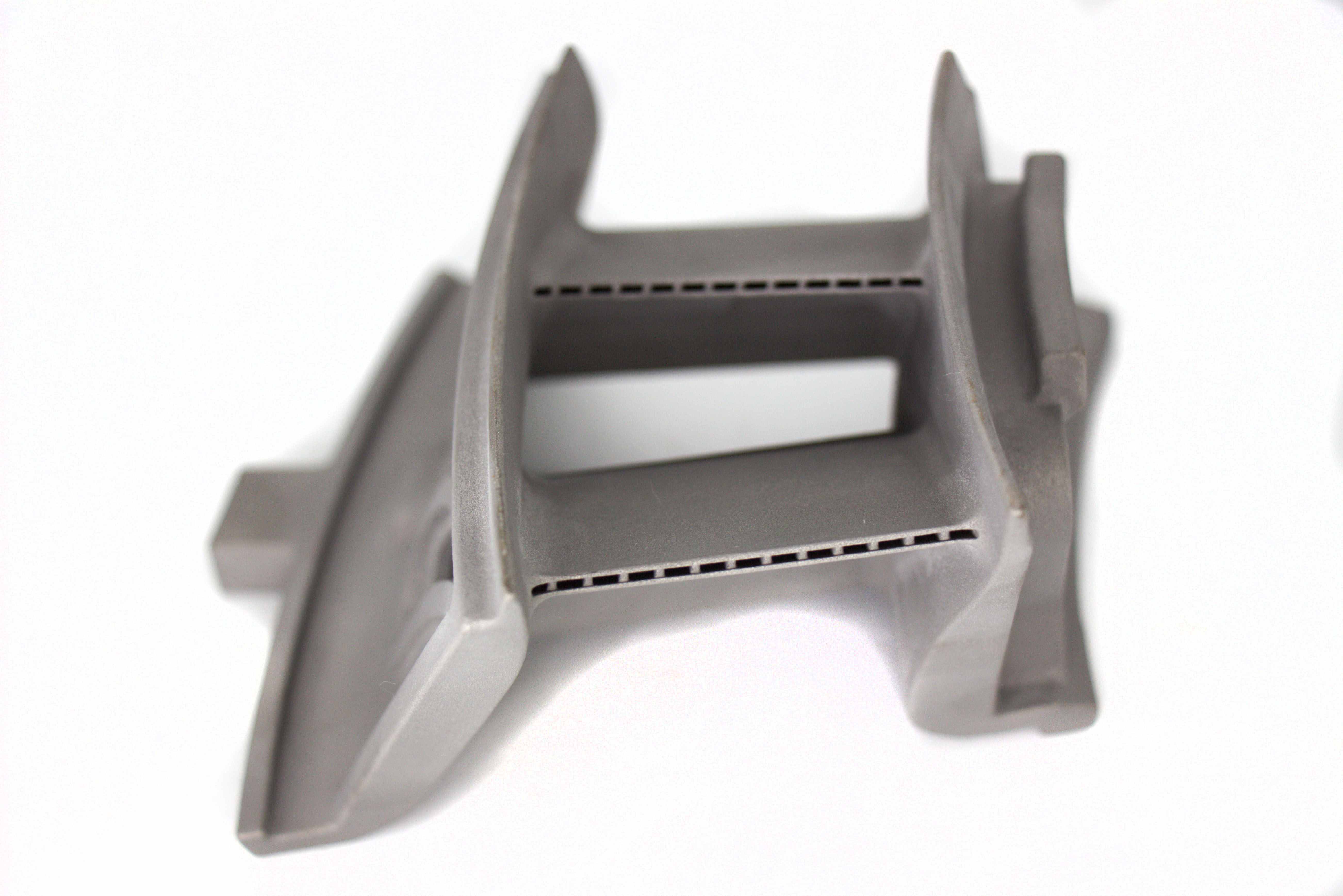

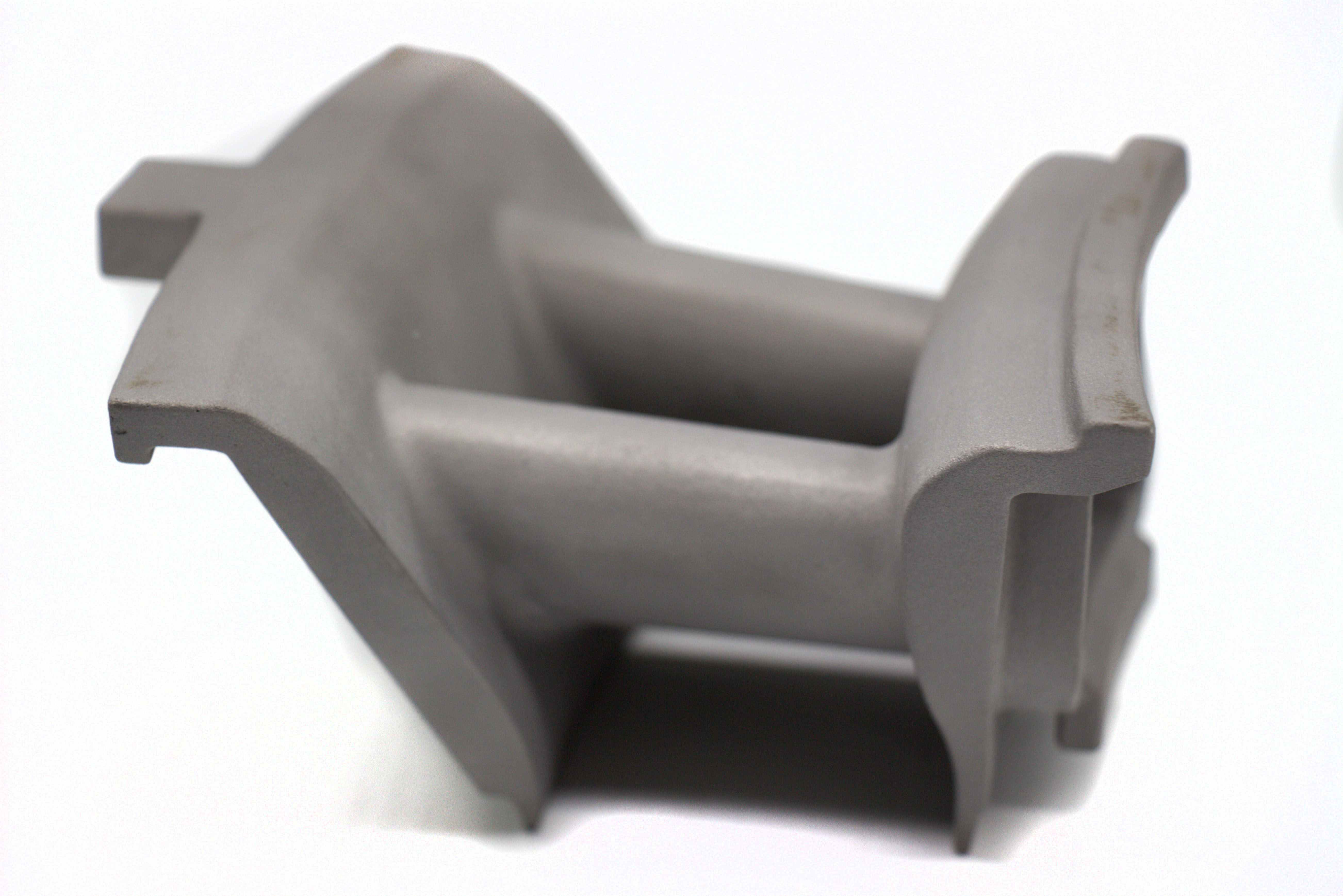

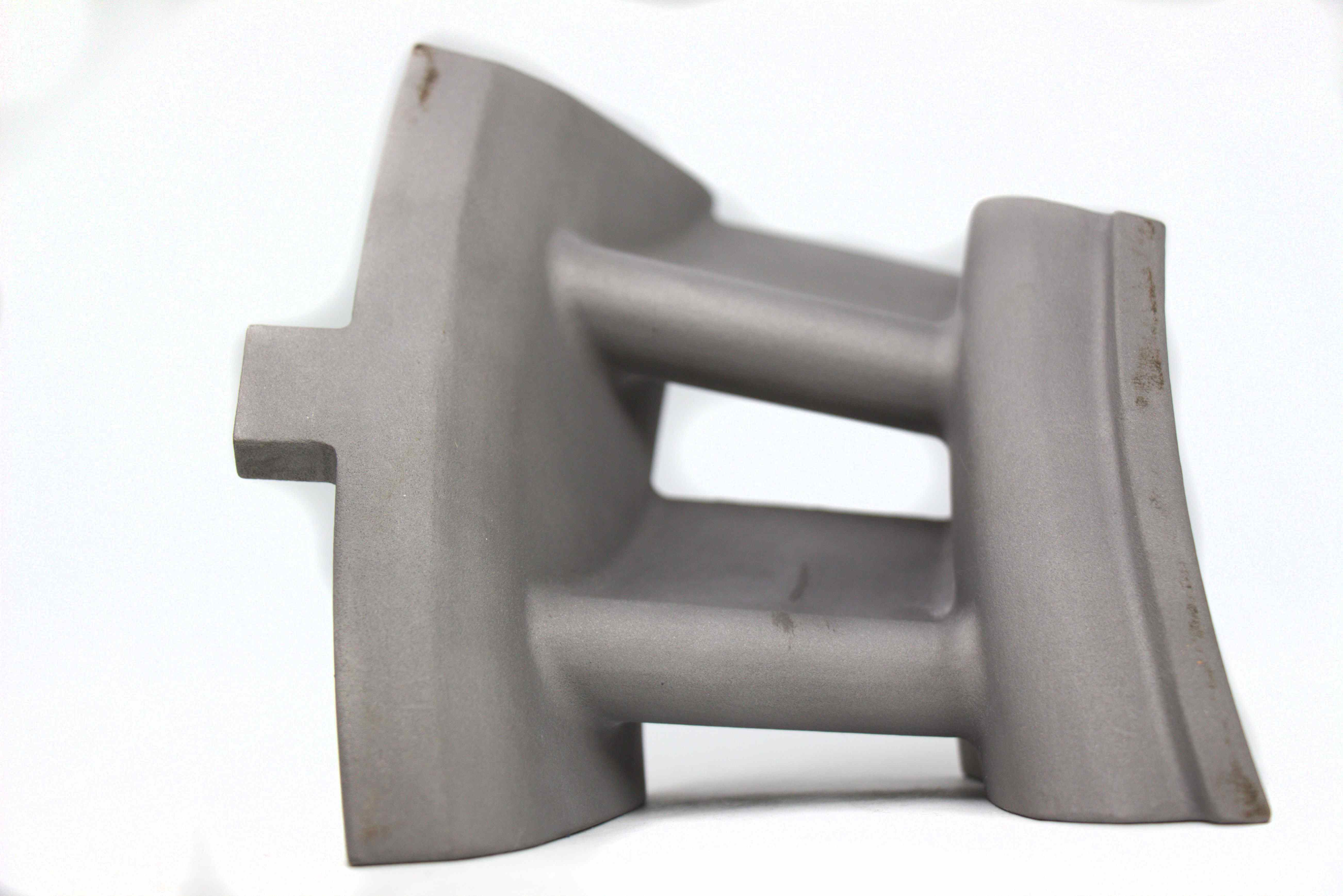

Design Freedom and Complex Geometry Advantages

One of the most significant advantages of using 3D printing for Inconel 718 is the ability to create geometrically complex structures that are impossible to machine or cast. Examples include:

Conformal cooling channels for turbine blades or combustion liners, improving thermal gradients and component life

Topology optimized lightweight structures, achieving 30–50% mass reduction while maintaining mechanical integrity

Lattice structures with tailored stiffness and thermal conductivity

Studies show that AM-optimized designs can improve component performance and reduce failure rates in cyclic thermal environments, especially in aerospace and power generation applications.

Cost and Lead Time Benefits for Custom Parts

For low- to medium-volume production and highly customized parts, 3D printing offers significant cost and time advantages:

Tool-less manufacturing: eliminates the need for expensive molds or dies, saving USD 20,000–100,000 in upfront tooling costs

Rapid prototyping and iteration: lead times reduced from 12–16 weeks (casting) to 2–4 weeks (AM)

On-demand production: enables digital inventory and decentralized manufacturing models

Such advantages are critical for industries with fast design cycles or urgent maintenance, repair, and overhaul (MRO) needs.

Enhanced Material Properties via Additive Processes

Modern AM processes such as Hot Isostatic Pressing (HIP) further elevate the performance of 3D printed Inconel 718 components:

Porosity reduction: HIP can achieve near 100% density (>99.9%), enhancing fatigue life and creep resistance

Grain refinement: Controlled thermal gradients during Powder Bed Fusion produce finer microstructures compared to cast materials

Residual stress relief: Optimized thermal post-processing stabilizes mechanical properties for high-temperature service

In independent testing, HIP-treated Inconel 718 AM parts have demonstrated fatigue lives comparable to, or exceeding, forged equivalents, with superior geometric precision.

In summary, 3D printing enables engineers to fully leverage the exceptional high-temperature capabilities of Inconel 718, delivering innovative part designs with optimized performance and economic advantages.

Key Factors Affecting Inconel 718 Maximum Service Temperature in 3D Printed Parts

Achieving optimal maximum service temperature in 3D printed Inconel 718 components requires careful control of manufacturing parameters and post-processing. Several critical factors influence thermal stability, mechanical performance, and long-term durability of parts operating at elevated temperatures.

Printing Process Parameters

The choice of the 3D printing process and parameter optimization directly impacts the material microstructure and high-temperature capability.

Powder Bed Fusion (PBF) remains the preferred method for high-precision Inconel 718 components. Key process parameters include:

Laser power and scan speed: affecting melt pool stability and porosity (<0.1% desired)

Layer thickness: 40–60 μ,m typical for aerospace applications

Build orientation: influences grain growth; vertical builds promote columnar grain,s enhancing creep resistance

Inert atmosphere: oxygen <100 ppm to avoid oxide inclusions that degrade high-temp properties

Optimized PBF processes consistently achieve >99.9% density, minimal residual stress, and fine equiaxed grain structures, contributing to superior elevated temperature strength and fatigue life.

Post-Processing Treatments

Post-processing is essential to unlocking the full thermal potential of 3D printed Inconel 718 parts. The key treatment is Heat Treatment, typically following the AMS 5664/5662 specification:

Solution annealing: 980–1065°C for 1–2 hours to dissolve precipitates and homogenize microstructure

Aging treatment: dual-step aging at ~720°C (8 hrs) + ~620°C (8 hrs) to precipitate γ' and γ'' phases

Proper heat treatment significantly improves high-temperature mechanical properties:

Condition | UTS @ 650°C | Creep Rupture Life (650°C/100 MPa) |

|---|---|---|

As-printed | ~700–800 MPa | <1000 hours |

Heat-treated | ~950–1050 MPa | >5000 hours |

Additionally, Hot Isostatic Pressing (HIP) can be combined with heat treatment to eliminate internal porosity and further enhance fatigue life under thermal cycling.

Surface Finishing Impact on High-Temp Durability

Surface condition plays a pivotal role in oxidation resistance and crack initiation at elevated temperatures. Key Surface Treatment methods include:

Mechanical polishing to Ra ≤ 0.8 μm, reducing stress concentration points

Shot peening to induce compressive surface stress, improving fatigue life

Protective coatings (Al-rich, Cr-based) to inhibit oxidation in extreme environments (>700°C)

In aerospace and energy applications, surface engineering can extend component life by 2–3× in high-temperature service compared to untreated surfaces.

In conclusion, optimizing printing parameters, heat treatment, HIP, and surface finishing is critical to achieving maximum service temperature performance in custom 3D printed Inconel 718 parts.

Industry Applications: Custom 3D Printed Inconel 718 High-Temp Parts

The ability to 3D print Inconel 718 components with optimized geometry and tailored high-temperature performance is driving adoption across multiple industries. Below are key sectors where custom 3D printed Inconel 718 parts are making significant impacts.

Aerospace Components: Combustor Liners, Nozzles, Blades

In the Aerospace and Aviation sector, Inconel 718 is a primary material for parts exposed to sustained temperatures around 650–700°C:

Combustor liners and transition ducts: leverage 3D printing to integrate conformal cooling channels, improving thermal efficiency and reducing component weight by up to 30%.

Turbine nozzles and guide vanes: benefit from optimized aerodynamics and fine lattice structures that enhance heat dissipation.

Small blades and vanes: AM enables rapid prototyping and MRO (Maintenance, Repair, and Overhaul), reducing lead times from 6–9 months (casting) to <6 weeks.

Using heat-treated and HIP-processed Inconel 718, aerospace manufacturers are achieving creep rupture lives exceeding 5,000–8,000 hours at 650°C, meeting FAA and EASA certification standards.

Energy and Power Sector: Turbine Components, Heat Exchangers

The Energy and Power industry increasingly utilizes custom 3D printed Inconel 718 parts in gas turbines, steam plants, and advanced heat exchanger systems:

Turbine stator segments: AM enables optimized cooling geometries, resulting in 15–25% fuel efficiency gains.

Microturbines: compact, high-speed rotors printed in Inconel 718 operate continuously at 650–700°C, with tested MTBF (Mean Time Between Failure) exceeding 20,000 hours.

Heat exchangers: 3D printed Inconel 718 enables novel compact heat exchanger designs with surface area density >5,000 m²/m³, critical for advanced supercritical CO₂ cycles.

The capability to produce low-porosity, high-ductility Inconel 718 AM parts enables operators to achieve longer service life and lower maintenance costs in harsh environments.

Automotive and Motorsports: Turbocharger Housings, Exhaust Components

High-performance Automotive and motorsports applications benefit from 3D printed Inconel 718 components that must withstand cyclic thermal loads of up to 700°C:

Turbocharger housings: AM enables lightweight, integrated housings with internal cooling paths, reducing underhood temperatures and improving engine response.

Exhaust manifolds and collectors: printed Inconel 718 designs reduce weld seams and improve reliability under aggressive thermal cycling seen in motorsport environments.

Industry testing (FIA GT3 class) shows that AM Inconel 718 exhaust parts maintain mechanical integrity for >1,000 racing hours at peak temperatures of 700–750°C, outperforming conventional stainless steel solutions.

Optimizing Design for Maximum Temperature Performance

Achieving the best maximum service temperature for 3D printed Inconel 718 components requires more than material selection—it demands a rigorous design-for-performance approach. This section highlights proven design strategies that enhance thermal durability and reliability in extreme environments.

DFAM Techniques for Thermal Stability

Design for Additive Manufacturing (DFAM) enables engineers to tailor part geometries for high-temperature performance:

Stress relief features: incorporating radiused fillets and gradual wall transitions minimizes localized stress concentrations, reducing crack initiation under thermal cycling.

Optimized wall thickness: balancing thermal mass with stiffness improves heat dissipation and dimensional stability. For example, turbine nozzles designed with ~1.5–2 mm wall sections demonstrate better high-cycle fatigue resistance.

Strategic lattice incorporation: Lightweight lattices can dampen thermal expansion stresses and enhance surface-to-volume ratios for cooling efficiency.

Advanced finite element analysis (FEA) and computational fluid dynamics (CFD) simulations guide these DFAM optimizations, ensuring robust performance in real-world thermal loading scenarios.

Material and Build Parameter Selection Guidelines

Maximizing temperature capability also depends on meticulous material and process parameter selection:

Powder specification: aerospace-grade Inconel 718 powder (per AMS 7002) with spherical morphology and oxygen content <0.02 wt% is recommended for consistent high-temp properties.

Build parameters:

Laser power: 200–400 W (single-laser PBF)

Scan strategy: island or stripe scanning to control residual stresses

Build orientation: Aligning critical load-bearing features with the build direction enhances grain alignment for improved creep resistance.

Empirical studies confirm that optimized PBF process windows can elevate tensile strength by 10–15% at 650–700°C compared to default build settings.

Post-Processing Validation and Quality Control

Ensuring long-term high-temperature reliability requires comprehensive post-processing validation:

Non-destructive testing (NDT):

CT scanning detects internal porosity down to ~50 μm.

X-ray inspection validates weld-like features and complex internal geometries.

Creep and fatigue testing: conducted per ASTM E139 and ASTM E466 for elevated temperature life validation.

Thermal exposure testing: parts undergo cyclic exposure tests (e.g., 650–700°C for 1,000+ hours) to simulate service conditions and verify dimensional stability and oxidation resistance.

By combining optimized design, rigorous process control, and robust validation, engineers can fully exploit the thermal capabilities of 3D printed Inconel 718 and confidently deploy parts in the harshest environments.