Inconel 625 3D Printing with CNC Post Machining: Order Precision Inconel Parts Fast

Introduction

Inconel 625 is a nickel-based superalloy renowned for its exceptional mechanical strength, corrosion resistance, and high-temperature stability. These properties make it a top choice for industries such as aerospace, energy, and chemical processing. By combining advanced additive manufacturing with precision CNC post machining, engineers can rapidly produce complex, high-precision Inconel 625 parts tailored for demanding applications. Modern 3D printing service platforms, such as this dedicated 3D printing service, enable the fast fabrication of intricate geometries. Complementary CNC machining processes ensure tight tolerances and excellent surface finishes, delivering parts that meet the most stringent industrial standards.

Why Choose Inconel 625 for Additive Manufacturing?

Key Material Properties of Inconel 625

Inconel 625 is valued for its superior strength and corrosion resistance across a wide range of extreme environments. It maintains mechanical integrity at temperatures exceeding 870°C and offers excellent resistance to oxidation, seawater, and various acids. The alloy also demonstrates high fatigue life and excellent weldability, which further enhances its suitability for complex, high-performance parts. Inconel 625’s unique material characteristics make it ideal for advanced superalloy manufacturing applications, providing designers with the flexibility to meet rigorous engineering requirements.

Application Advantages in Complex Parts

Additive manufacturing of Inconel 625 enables the production of highly complex geometries that are difficult or impossible to achieve using traditional subtractive processes. Features such as thin walls, intricate internal channels, and conformal cooling structures can be printed directly from CAD models, with minimal tooling or setup costs. Engineers can quickly iterate designs, leading to faster innovation cycles and optimized performance. A dedicated Inconel 625 additive manufacturing workflow ensures that components are built to exact specifications, supporting demanding use cases in aerospace, energy, and chemical processing industries.

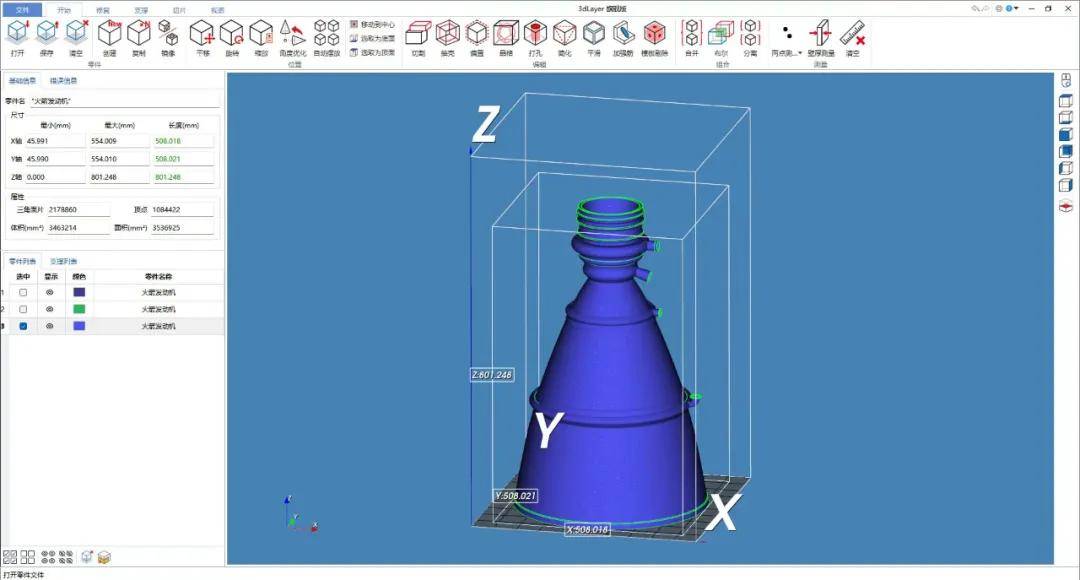

3D Printing Process for Inconel 625 Parts

Recommended 3D Printing Technologies

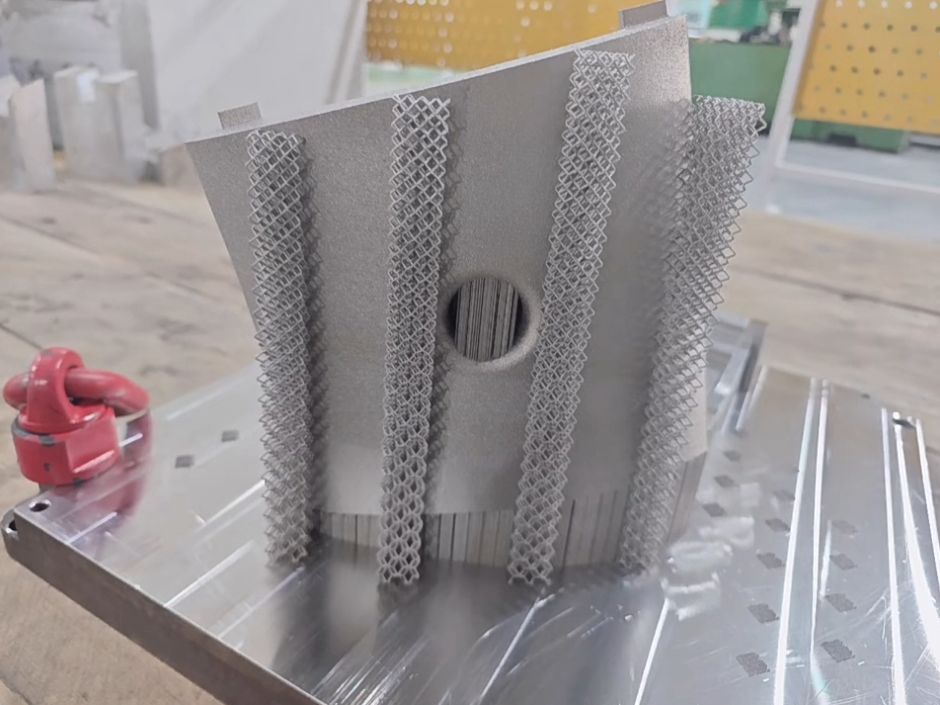

Inconel 625 is particularly well-suited for laser powder bed fusion (PBF) processes due to its excellent weldability and thermal properties. Two of the most commonly used technologies are Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS). These methods enable precise layer-by-layer fabrication of dense metal parts with excellent mechanical properties. Key process parameters, such as laser power, scan speed, and build orientation, can be optimized to ensure minimal porosity, uniform microstructure, and high dimensional accuracy. SLM and DMLS are ideal for producing thin-walled structures, complex internal features, and lightweight lattice designs with Inconel 625.

Benefits of Additive Manufacturing for Inconel 625

Additive manufacturing offers significant advantages over conventional methods for producing Inconel 625 components. Design freedom allows engineers to incorporate functional features and optimize weight without compromising strength. This results in improved part performance and system efficiency. Additionally, additive manufacturing supports rapid prototyping and small-batch production, which helps companies reduce time-to-market and minimize inventory costs. Many organizations leverage rapid prototyping services to accelerate the development of innovative Inconel 625 parts for critical applications in aerospace, marine, and chemical industries.

Importance of CNC Post Machining for Inconel 3D Printed Parts

Achieving Tight Tolerances and Surface Finishes

Although 3D printing delivers excellent geometric flexibility, post-processing is essential to meet the tight tolerances and surface finish requirements of precision Inconel 625 components. CNC machining enables dimensional accuracy up to ±0.02 mm, ensuring that critical features align with engineering specifications. Additionally, surface roughness can be reduced to Ra < 0.8 µm, providing smoother surfaces for sealing or mating components. In applications such as aerospace or fluid-handling systems, achieving these levels of precision is vital. For complex internal or hard-to-access features, Electrical Discharge Machining (EDM) is often used to achieve sharp edges and fine detail without inducing mechanical stress.

Hybrid Process Flow: 3D Printing + CNC Machining

A hybrid manufacturing workflow combining additive and subtractive processes offers the best of both worlds. The typical sequence includes 3D printing the near-net shape component, followed by heat treatment to optimize material properties, then CNC machining to achieve the final dimensional accuracy and surface quality. Finally, specialized surface treatment processes can be applied to enhance corrosion resistance or wear performance. This integrated approach reduces lead times and production costs while ensuring that Inconel 625 components meet stringent industrial standards. The flexibility of this workflow makes it ideal for producing high-value, custom-engineered parts across multiple industries.

Typical Applications of Inconel 625 3D Printed and Machined Parts

Aerospace Components

Inconel 625 is widely used in aerospace applications that demand exceptional strength, corrosion resistance, and thermal stability. Components such as gas turbine blades, guide vanes, and sealing rings are exposed to extreme temperatures and dynamic loads. The combination of additive manufacturing and CNC machining enables engineers to produce lightweight, high-precision parts optimized for aerospace performance. Companies in the aerospace and aviation sector benefit from the ability to fabricate geometries that enhance fuel efficiency, reduce emissions, and improve overall engine reliability.

Chemical and Marine Equipment

In the chemical processing and marine industries, Inconel 625 is valued for its outstanding resistance to chloride-induced corrosion, acids, and seawater. Heat exchangers, pressure vessels, and valves are common applications where Inconel 625’s durability ensures long service life in aggressive environments. Additive manufacturing allows for the creation of optimized flow paths and compact designs, while CNC machining guarantees the precision required for sealing and assembly. The energy and power sector also leverages Inconel 625 components for critical systems exposed to harsh chemical and thermal conditions.

Custom Tooling and Industrial Parts

Custom tooling, high-wear molds, and specialized equipment components are additional use cases for Inconel 625. The alloy’s high strength and fatigue resistance make it suitable for demanding industrial environments. Additive manufacturing enables rapid production of bespoke designs, while CNC post-processing ensures these parts meet exact dimensional and functional requirements. Manufacturers in manufacturing and tooling applications rely on Inconel 625 for tools and components that must perform reliably under extreme stress and wear conditions.

How to Order Precision Inconel 625 3D Printed Parts with CNC Finishing

Selecting Materials and Processing Options

When ordering Inconel 625 components, it is important to select the correct material grade and processing workflow to match the application’s performance requirements. A comprehensive 3D printing materials database provides detailed information on Inconel 625 properties, as well as compatible post-processing options. Engineers can review mechanical properties, corrosion resistance, and recommended heat treatments to ensure optimal part performance.

Optimizing Lead Time and Quality

To achieve the best results, it is advisable to collaborate with a qualified service provider that specializes in both additive manufacturing and CNC machining of Inconel 625. By utilizing superalloy 3D printing services with integrated post-processing capabilities, customers can streamline production and reduce lead times. Key considerations include part orientation for printability, allowances for machining, and any required surface treatments. With proper planning, companies can efficiently order precision Inconel 625 parts that meet the highest quality standards for critical applications.

Conclusion

Inconel 625 offers a unique combination of strength, corrosion resistance, and high-temperature stability, making it an excellent choice for advanced engineering applications. By leveraging the precision and flexibility of additive manufacturing, combined with high-accuracy CNC post machining, engineers can produce custom Inconel 625 parts that meet exacting industry standards. This hybrid manufacturing approach supports faster product development and superior component performance. For industries looking to innovate and streamline production, integrating powder bed fusion and CNC machining workflows provides a proven pathway to success with Inconel 625 components.