LMD 3D Printing Service: Precision Superalloy Deposition for Repairs & Enhancements

Introduction

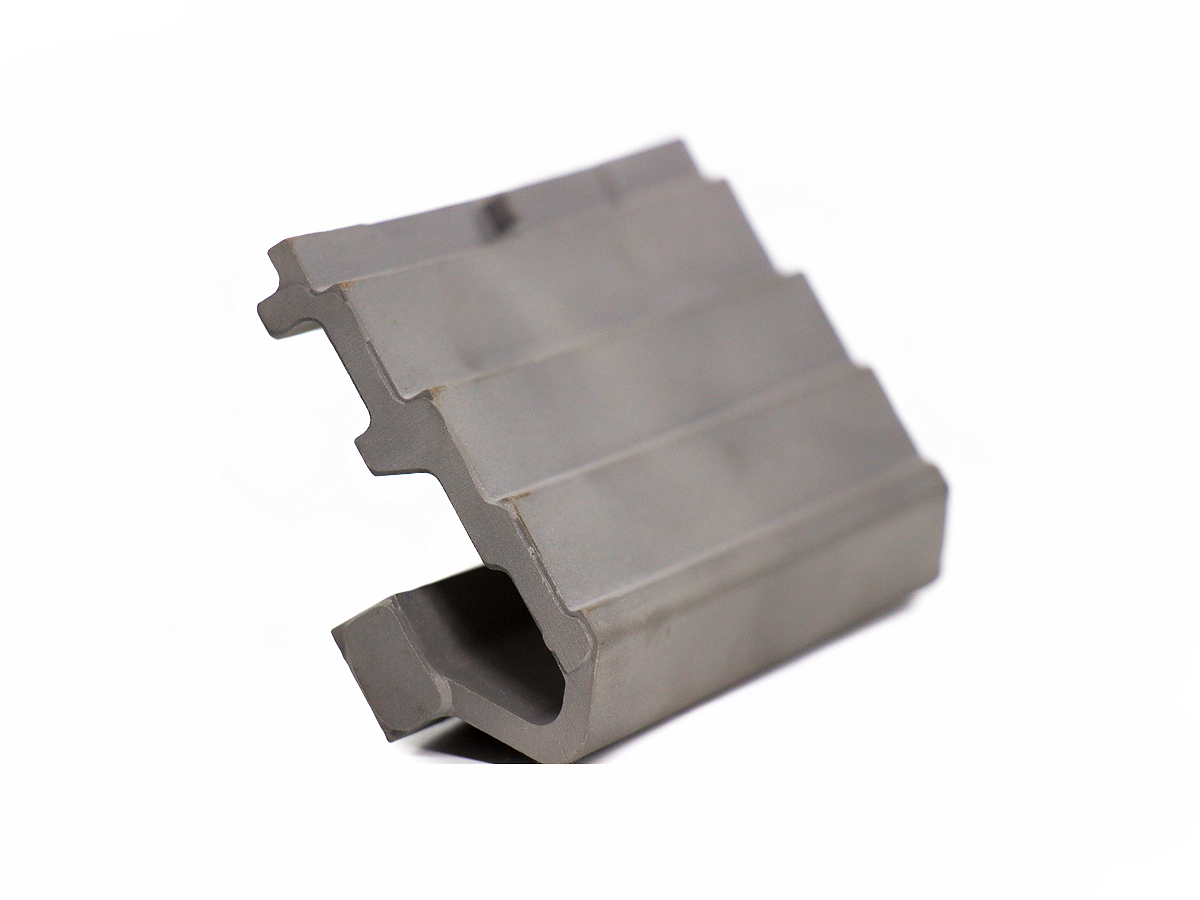

Laser Metal Deposition (LMD) is an advanced additive manufacturing technology specialized for precision deposition and repair of high-performance superalloy components. Utilizing a laser beam to melt powdered alloys precisely onto existing parts, LMD seamlessly integrates materials like Inconel 718 and Hastelloy C-276. This method efficiently restores damaged components or adds advanced features, reducing repair costs by up to 50% and shortening downtime significantly.

Compared to traditional welding or machining, LMD offers greater accuracy, minimal thermal distortion, and optimal metallurgical quality, ideal for demanding industries such as aerospace, energy, and automotive.

Applicable Material Matrix

Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Max Operating Temp. (°C) |

|---|---|---|---|---|

8.19 | 1375 | 1100 | 700 | |

8.44 | 930 | 517 | 982 | |

8.89 | 790 | 355 | 1038 | |

8.97 | 860 | 450 | 1150 | |

8.38 | 1175 | 850 | 800 |

Material Selection Guide

Inconel 718: Optimal for repairing and enhancing turbine blades and aerospace components, offering high tensile strength (1375 MPa) and excellent fatigue resistance.

Inconel 625: Ideal for marine and chemical equipment repair due to superior corrosion resistance and high-temperature stability.

Hastelloy C-276: Recommended for corrosion-resistant overlays and repairs in aggressive chemical processing environments.

Haynes 230: Suitable for restoring high-temperature furnace components and gas turbine combustion chambers, providing excellent oxidation resistance up to 1150°C.

Stellite 6B: Preferred for adding wear-resistant surfaces and enhancing high-temperature durability in demanding industrial applications.

Process Performance Matrix

Attribute | LMD Performance |

|---|---|

Dimensional Accuracy | ±0.2 mm |

Density | >99.5% |

Layer Thickness | 0.1–0.5 mm |

Surface Roughness | Ra 10–15 μm |

Minimum Feature Size | 0.5 mm |

Process Selection Guide

Repair & Enhancement: Ideal for precision restoration of worn or damaged superalloy components, significantly extending their service life.

Material Efficiency: Minimal waste with targeted powder deposition, typically reducing material costs by 30–50%.

Reduced Downtime: Fast on-site repair capability, minimizing equipment downtime and logistical challenges.

Metallurgical Integrity: Superior bonding and minimal thermal stress ensure high-quality, durable repairs.

Case In-Depth Analysis: LMD Repair and Enhancement of Inconel 718 Aerospace Turbine Components

An aerospace client faced significant downtime due to damaged turbine blades in gas turbine engines, requiring rapid repair and enhancement. Employing our LMD 3D printing service with Inconel 718, we precisely restored the worn blade surfaces and added advanced features, achieving full density (>99.5%) and tensile strength of 1375 MPa. The repaired components reduced downtime by 60%, improved fatigue performance by 25%, and lowered overall repair costs by approximately 50%. Post-processing involved precise CNC machining and rigorous heat treatment to ensure optimal mechanical properties.

Industry Applications

Aerospace and Aviation

On-site restoration of turbine blades and compressor parts.

Precision deposition of advanced cooling channels in engine components.

Structural enhancement of airframe components to improve fatigue resistance.

Energy and Power

Repair of high-temperature boiler and heat exchanger parts.

Restoration of critical components in nuclear reactors.

Surface enhancement for renewable energy turbine components.

Automotive

High-performance coatings on engine valves and turbochargers.

Precision repair of transmission gears and drive shafts.

Structural reinforcements on high-wear surfaces in motorsport vehicles.

Mainstream 3D Printing Technology Types for Industrial Applications

Selective Laser Melting (SLM): High-density metal components with intricate features.

Electron Beam Melting (EBM): Ideal for producing aerospace-grade titanium and superalloy components.

Binder Jetting: Cost-effective for rapid prototyping and batch manufacturing of moderate complexity parts.

Direct Metal Laser Sintering (DMLS): Excellent for detailed, complex parts requiring high precision.

Ultrasonic Additive Manufacturing (UAM): Best suited for multi-material integration without melting, ideal for embedding electronics and sensors.

FAQs

What are the advantages of using LMD technology for repairing industrial superalloy components?

Which superalloys are most suitable for LMD-based repairs and enhancements?

How does LMD technology compare to traditional welding or machining methods in terms of performance?

What post-processing steps are required after LMD deposition?

Is LMD suitable for on-site repair and how does it reduce downtime for industrial equipment?