Boron Carbide (B4C) 3D Printing: Lightweight Nuclear Neutron Shielding Module Parts

Introduction

Boron Carbide (B₄C) 3D printing offers an advanced solution for manufacturing lightweight, highly efficient neutron shielding components essential for nuclear applications. Using state-of-the-art ceramic 3D printing technologies such as Binder Jetting and Material Extrusion, Boron Carbide (B₄C) components achieve excellent neutron absorption, hardness, and chemical stability.

Compared to traditional pressing or casting methods, B₄C 3D printing enables the rapid production of complex, weight-optimized shielding modules customized for specific reactor and radiation control system requirements.

Applicable Material Matrix

Material | Purity (%) | Neutron Absorption Cross-Section (barns) | Hardness (HV10) | Density (g/cm³) | Max Operating Temp. (°C) |

|---|---|---|---|---|---|

>98% | ~600 | 2700–3000 | 2.52 | 1000 |

Material Selection Guide

Boron Carbide (B₄C): Ideal for lightweight neutron shielding panels, reactor control rods, and nuclear radiation containment systems due to its high neutron absorption efficiency, ultra-high hardness, and chemical inertness.

Process Performance Matrix

Attribute | Boron Carbide 3D Printing Performance |

|---|---|

Dimensional Accuracy | ±0.1–0.2 mm |

Density (after sintering) | >96% Theoretical Density |

Minimum Wall Thickness | 1.0–2.0 mm |

Surface Roughness (As-Sintered) | Ra 5–10 μm |

Feature Size Resolution | 150–250 μm |

Process Selection Guide

Neutron Absorption Efficiency: B₄C has one of the highest neutron absorption cross-sections, making it indispensable for critical radiation shielding and control systems.

Lightweight Protection: With a low density (~2.52 g/cm³), B�������������C allows for highly effective radiation protection without the weight penalties associated with metal-based shields.

Chemical and Thermal Stability: B₄C resists oxidation, chemical corrosion, and degradation even at temperatures up to 1000°C.

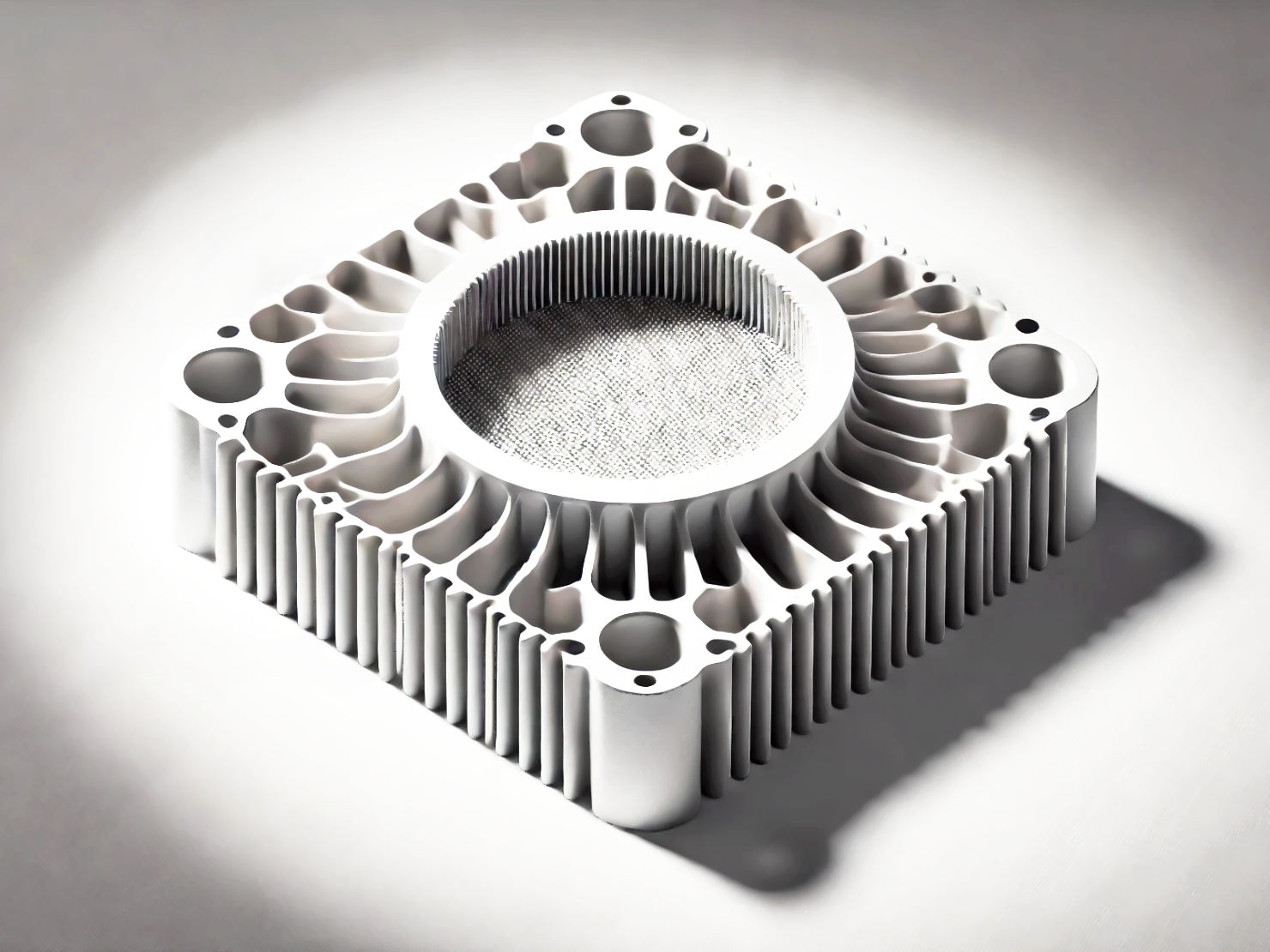

Complex and Customizable Shapes: 3D printing enables intricate designs with integrated mounting features, internal channels, and optimized mass distribution to fit restricted spaces.

Case In-Depth Analysis: Customized B₄C Neutron Shielding Modules for Nuclear Research Reactors

A nuclear research institute required neutron shielding modules that combined maximum neutron absorption efficiency with lightweight construction for integration into experimental reactor systems. Through our Boron Carbide 3D printing service, we manufactured customized B₄C panels and modules, achieving densities above 96%, neutron cross-sections near 600 barns, and dimensional tolerances within ±0.15 mm. Optimized honeycomb internal structures reduced module weight by 35% while maintaining shielding performance. Post-processing included surface smoothing and quality validation using neutron transmission testing.

Industry Applications

Nuclear Energy

Neutron shielding panels for atomic reactors and research facilities.

Customized control rods and radiation shielding inserts.

Lightweight portable radiation protection barriers.

Defense and Security

Neutron radiation shielding in military vehicles and nuclear submarines.

Radiation containment modules for portable nuclear materials storage.

Medical and Research

Neutron shielding components for radiation therapy systems.

Research laboratory radiation barriers and control apparatus.

Mainstream 3D Printing Technology Types for Boron Carbide Ceramic Parts

Binder Jetting: Best suited for scalable production of large or complex neutron shielding components.

Material Extrusion: Ideal for producing structural B₄C parts requiring robust mechanical properties post-sintering.

Vat Photopolymerization (SLA/DLP): Effective for intricate, high-precision lightweight B₄C components.

FAQs

Why is Boron Carbide ideal for 3D printed neutron shielding applications?

How does 3D printed B₄C compare to traditional neutron shielding materials?

What design advantages does B₄C 3D printing offer for nuclear applications?

What are the mechanical and thermal limits of B₄C 3D printed parts?

How is neutron absorption efficiency validated for 3D printed Boron Carbide shielding modules?