Can Binder Jetting produce titanium parts, and what are its advantages?

Can Binder Jetting Produce Titanium Parts, and What Are Its Advantages?

Feasibility of Titanium in Binder Jetting

Yes, Binder Jetting can be used to produce titanium parts, but it requires controlled post-processing to achieve suitable mechanical performance. Titanium powders such as Ti-6Al-4V (Grade 5) can be printed using Binder Jetting by applying a liquid binder to form a green part, which is then sintered and sometimes followed by hot isostatic pressing (HIP) to increase density and strength.

While Binder Jetting of titanium is still developing relative to EBM or SLM, it is a promising solution for specific use cases that require cost-effective, high-throughput production of non-critical titanium parts.

Key Advantages of Binder Jetting for Titanium

1. High Production Throughput

Binder Jetting builds entire layers at once without melting, resulting in significantly faster build rates compared to laser-based processes like Selective Laser Melting (SLM). This makes it ideal for batch production of small-to-medium-sized titanium parts where high volume and short lead times are priorities.

2. No Support Structures Required

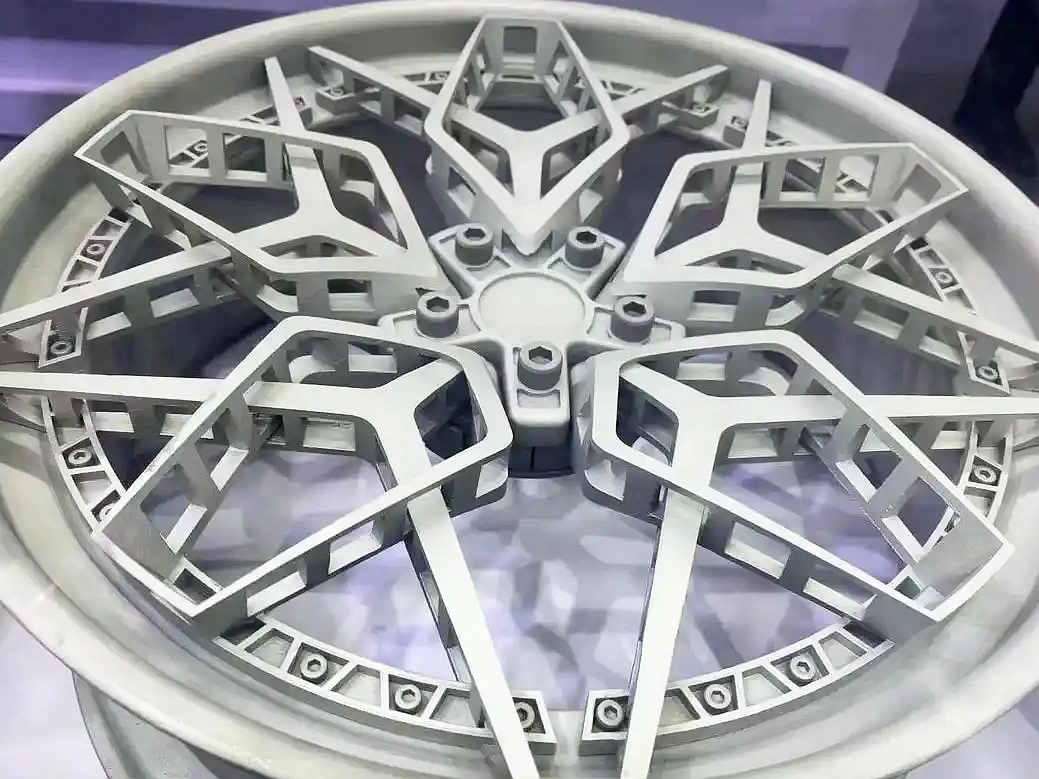

Since the part is surrounded by unsintered powder, Binder Jetting requires no dedicated support structures. This allows for highly complex geometries, internal cavities, and efficient part nesting—minimizing material waste and maximizing print volume.

3. Lower Thermal Stress and Distortion

As Binder Jetting does not involve localized melting, thermal gradients and residual stresses are minimal. This simplifies downstream processes and reduces the risk of distortion, especially important for parts with thin walls or intricate features.

4. Cost Efficiency

Binder Jetting offers cost advantages through:

Lower equipment energy consumption

Simple post-processing workflow

Scalability for non-critical titanium components in industrial, medical, or consumer products

With further sintering or HIP, part densities can approach 95–98%, which is suitable for applications with moderate structural demands.

Customer-Oriented Solutions and Services

We offer tailored solutions for titanium part production using Binder Jetting:

3D Printing Technologies:

Explore our Binder Jetting service and compare it with our Titanium 3D Printing options for various performance and volume requirements.

Titanium Material Selection:

Choose high-quality titanium alloys like Ti-6Al-4V for components that balance strength, corrosion resistance, and cost-effectiveness.

Post-Processing Capabilities:

Enhance final part performance with heat treatment, HIP, and CNC machining to meet industry-specific specifications.