What is the typical reduction in surface roughness achievable with HIP?

What Is the Typical Reduction in Surface Roughness Achievable with HIP?

Overview

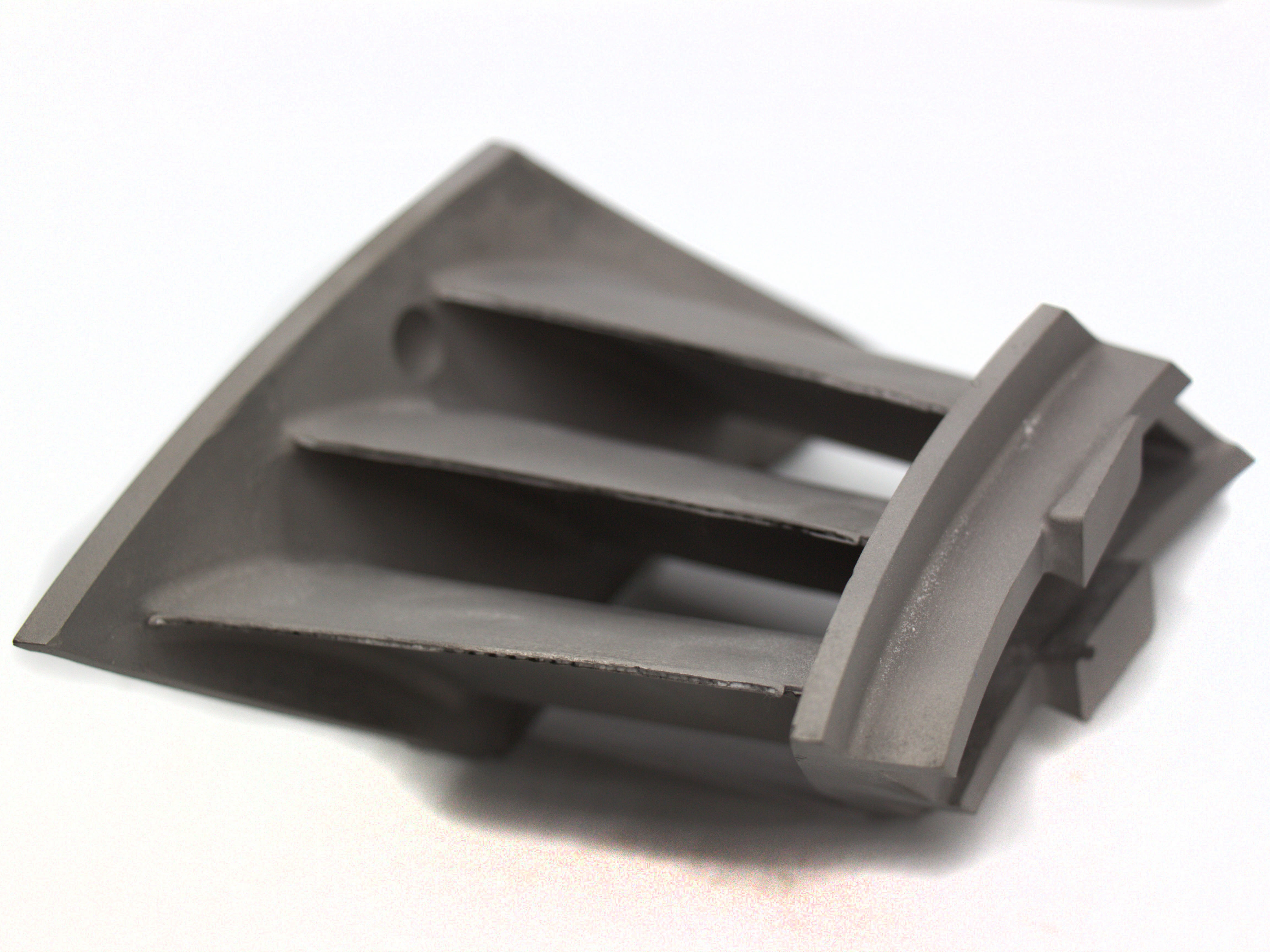

Hot Isostatic Pressing (HIP) is designed to improve the internal density and mechanical performance of 3D printed metal parts by eliminating porosity and healing subsurface defects. However, HIP is not a surface polishing process and does not directly reduce surface roughness (Ra) caused by layer-based fabrication or powder particle adhesion.

Surface Roughness Before and After HIP

As-Built Surface Roughness

Typical as-printed surface roughness values (Ra) from powder bed fusion processes such as SLM or DMLS range from:

Ra 8–15 µm on vertical and overhanging surfaces

Ra 4–7 µm on upward-facing flat surfaces

Post-HIP Surface Roughness

After HIP:

The surface roughness typically remains within ±0.5 µm of the as-printed value

The outer texture, powder adhesion marks, and layer lines are not removed

HIP does not reduce Ra significantly unless followed by additional finishing

Therefore, typical surface roughness reduction with HIP alone is negligible

Why HIP Is Still Valuable for Surface Integrity

While HIP does not visibly smooth the outer surface, it significantly enhances subsurface quality, which indirectly improves:

Resistance to crack initiation from surface flaws

Surface stability during polishing or machining

Uniformity for follow-up treatments like electropolishing or PVD coating

Achieving Final Surface Quality

To reduce surface roughness to Ra ≤ 0.2 µm for applications like medical implants or sealing interfaces, HIP must be followed by:

Summary Table

Process Stage | Typical Surface Roughness (Ra) |

|---|---|

As-printed (SLM/DMLS) | 8–15 µm |

After HIP | 7.5–15 µm |

After machining | 0.8–3.2 µm |

After electropolishing | 0.1–0.3 µm |

Recommended Services for Surface Optimization

Neway 3DP offers full workflows to achieve final surface specifications:

Hot Isostatic Pressing For structural consolidation and subsurface integrity

CNC Machining For dimensional control and Ra reduction

Surface Treatment Including polishing and coating for smooth, functional finishes