How does HIP reduce internal porosity in 3D printed parts?

How Does HIP Reduce Internal Porosity in 3D Printed Parts?

Understanding Porosity in Additive Manufacturing

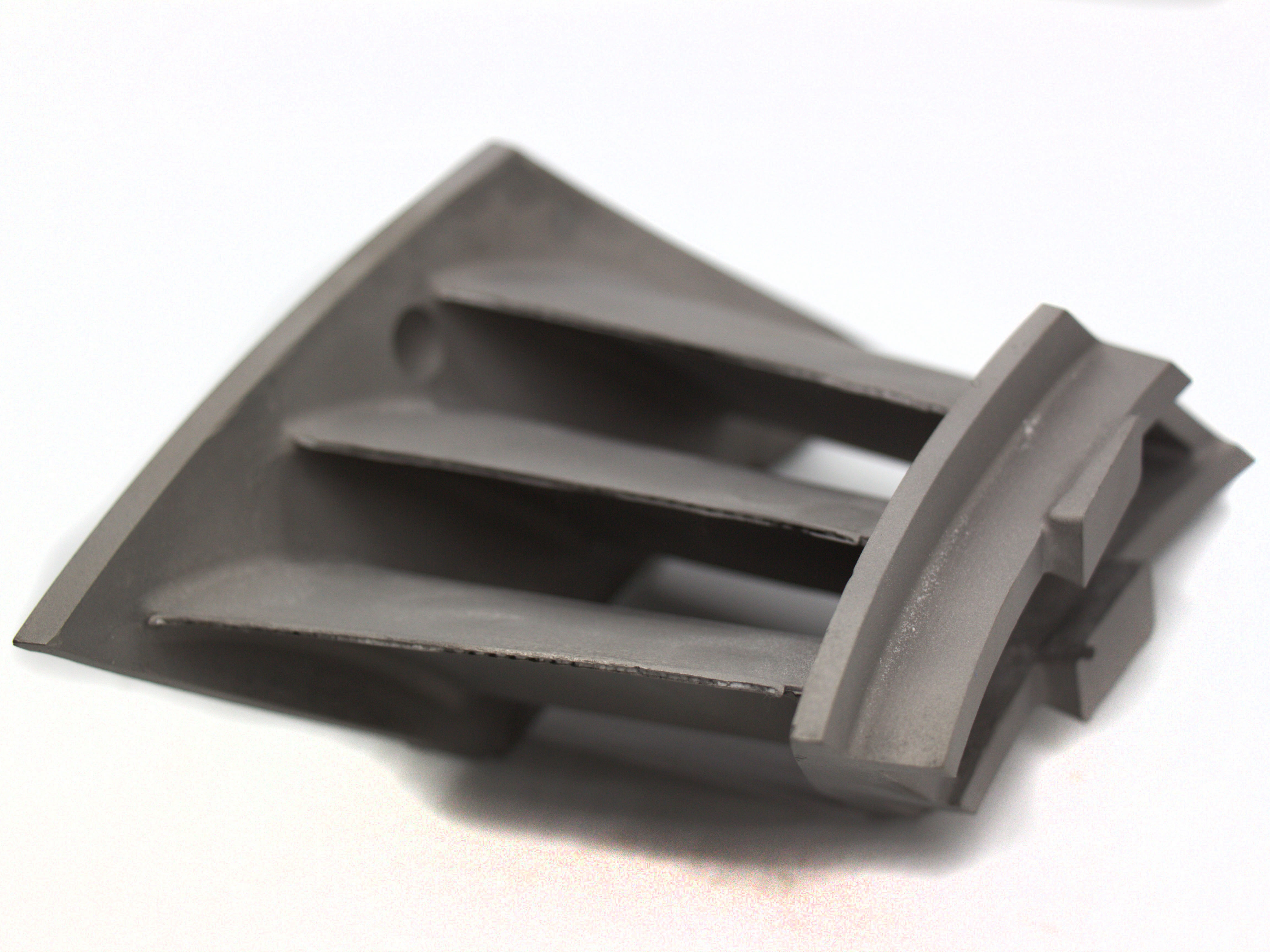

3D printed metal parts—especially those produced using SLM, DMLS, or EBM—often contain internal porosity due to incomplete fusion, gas entrapment, or powder packing variability. These voids reduce mechanical strength, fatigue life, and overall part reliability. Hot Isostatic Pressing (HIP) is a post-processing solution that eliminates such defects by combining high temperature and uniform gas pressure to densify the material.

Mechanism of Porosity Reduction

1. Isostatic Pressure Application

During HIP, the part is subjected to isotropic gas pressure (typically 100–200 MPa) in an inert atmosphere (usually argon). The pressure is applied uniformly in all directions, compressing the part from the outside in.

2. Elevated Temperature Activation

The part is heated to 90–95% of its melting point (900–1250°C depending on the material), allowing atomic diffusion to occur. The combination of heat and pressure softens the material around internal pores, enabling plastic deformation and diffusion bonding across void surfaces.

3. Void Closure and Material Flow

As the pressure compresses the pores, atoms migrate and fuse at pore surfaces, closing microvoids and collapsing defects. This process increases part density to >99.9%, transforming previously weak regions into solid, load-bearing material.

Effectiveness of HIP by Material

Ti-6Al-4V and Ti-6Al-4V ELI: HIP at ~920°C and 100 MPa for 2–4 hours eliminates gas pores, improving fatigue life in medical and aerospace parts

Inconel 718: HIP at ~1180°C removes solidification cracks and increases fracture resistance

Tool Steel 1.2709: Achieves uniform hardness and minimizes internal voids prior to aging

SUS316L: HIP reduces gas-induced porosity and improves ductility for pressure-containing applications

Benefits of HIP for Internal Porosity

Benefit | Result |

|---|---|

Eliminates microvoids | Increases mechanical strength and part density |

Improves fatigue performance | Prevents crack initiation under cyclic loading |

Enhances ductility | Enables improved impact and deformation resistance |

Increases thermal stability | Supports high-temperature structural integrity |

Comparison: As-Built vs. HIP-Treated

Property | As-Built Part | HIP-Treated Part |

|---|---|---|

Density | 98–99% | >99.9% |

Internal Porosity | 0.5–2.0% typical | <0.05% |

Fatigue Strength | Lower due to voids | Up to 3× improvement |

Fracture Resistance | Reduced at defect sites | Uniform material response |

Recommended Services from Neway 3DP

To eliminate porosity and improve part reliability, we offer:

Hot Isostatic Pressing For full densification and fatigue resistance in mission-critical components

Heat Treatment For final mechanical tuning post-HIP via aging or tempering

CNC Machining For finishing dimensional adjustments after thermal stabilization