How does HIP improve surface finish compared to traditional polishing methods?

How Does HIP Improve Surface Finish Compared to Traditional Polishing Methods?

Overview

Hot Isostatic Pressing (HIP) is primarily used to improve internal density, mechanical properties, and fatigue performance of 3D printed metal parts. While it is not a surface finishing method in the conventional sense, HIP can enhance certain aspects of surface quality that differ fundamentally from what is achieved through traditional mechanical polishing.

HIP vs. Traditional Polishing: Surface Finish Comparison

1. Subsurface Integrity Improvement

HIP improves the subsurface quality by closing near-surface pores and eliminating internal voids that may otherwise be exposed after mechanical finishing.

In materials like Ti-6Al-4V or Inconel 718, HIP prevents surface microcracks caused by underlying defects

The result is a more uniform, defect-free surface when subsequently polished or coated

2. Preservation of Complex Geometry

Unlike traditional polishing, which can remove detail or alter critical dimensions:

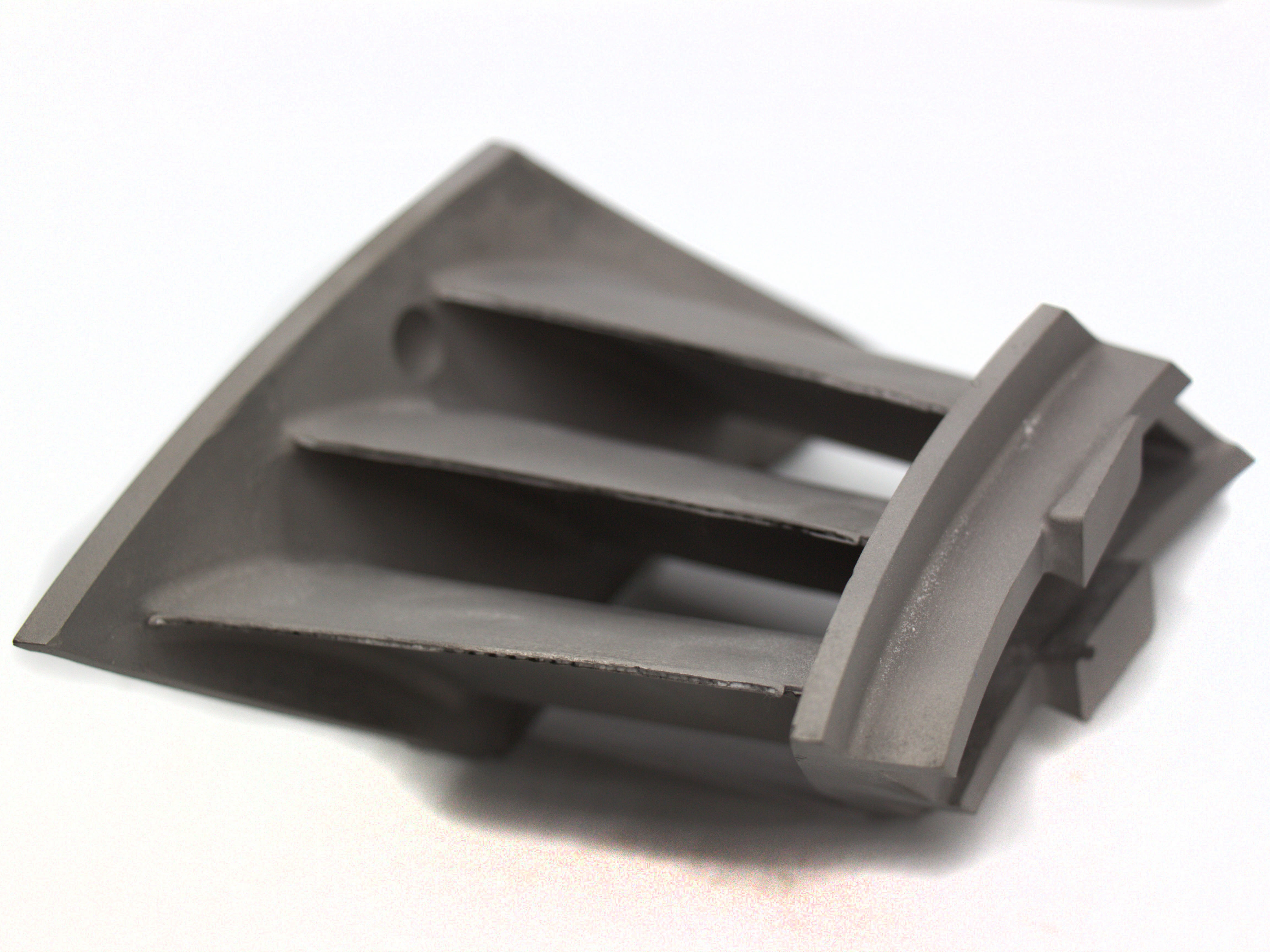

HIP is non-abrasive and isotropic, so it maintains fine features, thin walls, and complex internal structures without physical contact

This is ideal for parts with intricate geometries that cannot tolerate dimensional loss

3. No Mechanical Disturbance

Traditional polishing can introduce:

Surface deformation

Smearing of softer phases

Unintended rounding of sharp features

HIP avoids all of these, providing a structurally consistent and stress-free surface layer, ready for final finishing processes such as PVD coating or electropolishing.

4. Enhanced Post-Finish Outcomes

Because HIP removes sub-surface voids and stabilizes the microstructure, any subsequent polishing process becomes more effective:

Surface roughness levels (Ra) can be reduced to <0.2 µm more consistently

Final coatings adhere better due to reduced porosity and cleaner surface profiles

Limitations of HIP for Surface Finish

HIP does not directly smooth the surface or reduce as-printed roughness (e.g., Ra 8–12 µm)

Surface oxidation or discoloration may occur if not processed in a vacuum or inert environment

It is best used in combination with machining or chemical polishing for critical surface applications

Recommended Applications

Medical implants in Ti-6Al-4V ELI requiring a flaw-free surface prior to polishing

Sealing and load-bearing surfaces in Tool Steel 1.2709

Pressure vessel components in SUS316L

Recommended Services for Surface Optimization

Neway 3DP delivers enhanced surface quality with combined workflows:

Hot Isostatic Pressing For subsurface void elimination and structural uniformity

CNC Machining For critical dimension and final surface definition

Surface Treatment Including polishing, electropolishing, and PVD coating for final appearance and function