How does HIP enhance fatigue resistance in aerospace components?

How Does HIP Enhance Fatigue Resistance in Aerospace Components?

Porosity Elimination for Crack Resistance

In aerospace applications, fatigue failure is often initiated at internal defects or surface-connected pores. Hot Isostatic Pressing (HIP) removes such defects by applying uniform pressure (up to 200 MPa) and high temperature (typically 900–1250°C) in an inert atmosphere, consolidating the material into a fully dense structure. This is critical for parts produced via Powder Bed Fusion, where porosity and lack-of-fusion zones are common. HIP-treated components like turbine disks and structural brackets made from Inconel 718 or Ti-6Al-4V exhibit significantly reduced fatigue crack initiation.

Grain Structure Optimization

HIP not only eliminates internal porosity but also promotes uniform grain growth and stress relief. This improves the microstructural homogeneity of superalloy and titanium alloy components, reducing stress concentration zones that accelerate fatigue damage. Fine and equiaxed grains achieved during HIP contribute to increased resistance against crack propagation under high-frequency cyclic loading.

Studies have shown that HIP can increase the fatigue limit of aerospace-grade Ti-6Al-4V from ~500 MPa (as-printed) to over 700 MPa, depending on surface condition and part geometry.

Improved Performance in Load-Bearing and Rotating Parts

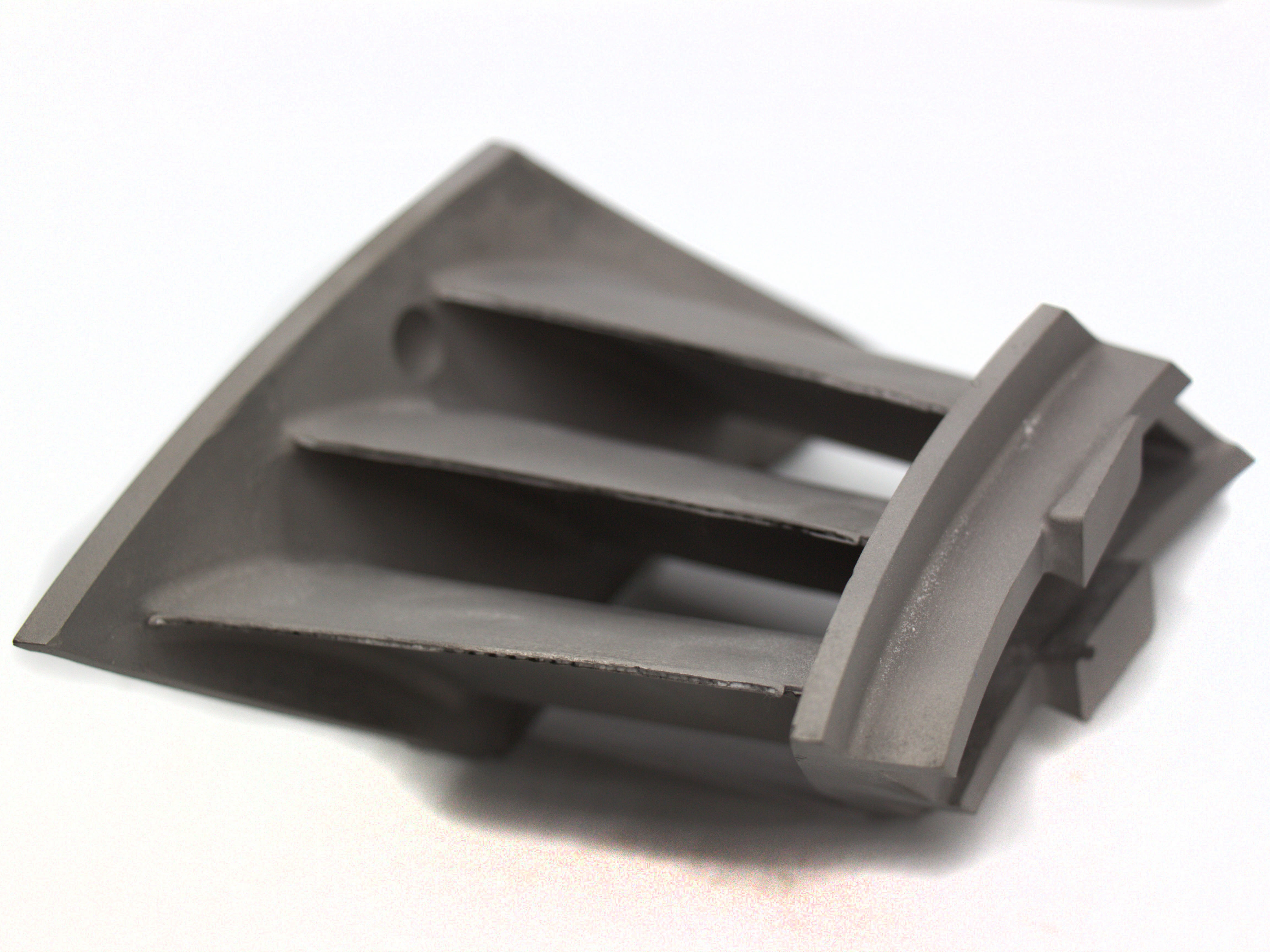

HIP-treated 3D printed components used in aerospace and aviation include compressor casings, impellers, blisks, and engine brackets. These parts endure high-stress cycles and vibration, making fatigue life a critical performance factor. HIP enhances their durability by extending the number of load cycles the material can withstand before failure, which is especially important for reducing lifecycle maintenance and inspection intervals in flight hardware.

Recommended Services for Aerospace Fatigue Resistance

Neway provides specialized services to help aerospace customers enhance fatigue resistance in critical parts:

Fatigue-Critical 3D Printing:

Titanium 3D Printing: Ideal for lightweight, fatigue-resistant airframe and engine parts.

Superalloy 3D Printing: For rotating and high-temperature fatigue-sensitive components.

HIP and Thermal Post-Treatment:

Hot Isostatic Pressing (HIP): Eliminates porosity and improves fatigue threshold.

Heat Treatment: Refines grain size and mechanical consistency.

Precision Finishing:

CNC Machining: Ensures dimensional control and removes surface irregularities that reduce fatigue life.