Does HIP introduce residual stresses during the strengthening process?

Does HIP Introduce Residual Stresses During the Strengthening Process?

Stress Relief Through Uniform Thermal and Pressure Loading

Hot Isostatic Pressing (HIP) is designed not to introduce but to relieve residual stresses that commonly form during additive manufacturing processes like Selective Laser Melting (SLM) or Directed Energy Deposition (DED). These stresses originate from rapid thermal gradients and layer-by-layer solidification. HIP applies isostatic pressure and high temperature in a uniform, inert atmosphere—usually argon—allowing the entire part to expand and densify uniformly. This results in thermal and mechanical equilibrium across the component, minimizing residual stress accumulation.

For components printed in Ti-6Al-4V, Inconel 718, or Stainless Steel 316L, HIP reduces pre-existing stress fields and stabilizes microstructures without introducing new deformation-related stresses.

Comparison with Conventional Stress-Inducing Processes

Unlike surface treatments (e.g., grinding or shot peening), HIP does not involve localized deformation or directional force application. This ensures that dimensional stability is preserved—an essential factor for aerospace, medical, and precision tooling applications. Additionally, HIP can serve as an effective substitute or complement to stress-relief heat treatment when combined with densification requirements.

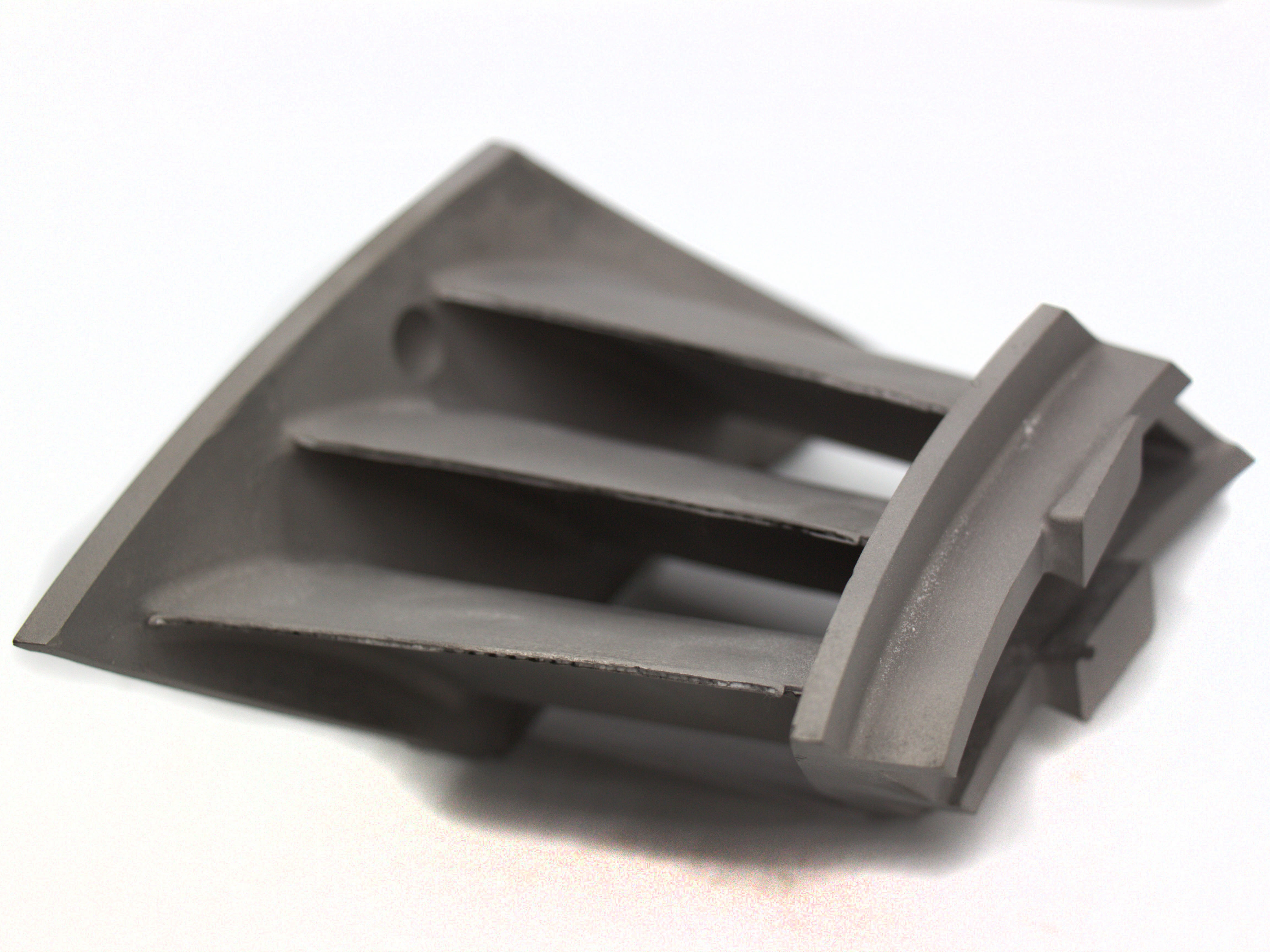

Metallurgical analyses post-HIP typically show reduced distortion in thin-walled and high-aspect-ratio components, especially in parts made from ceramic or superalloy materials, where dimensional tolerance is critical.

Net Benefit: Strength Without Residual Deformation

The final outcome of HIP is not residual stress generation but structural strengthening through pore elimination and microstructural uniformity. In fact, HIP is widely used in aerospace and medical industries specifically because it improves mechanical reliability without introducing new stress risks.

Recommended Services for Residual Stress Control and Strength Enhancement

Neway offers an optimized workflow for producing high-performance, low-stress parts:

Stress-Prone Material Solutions:

Titanium 3D Printing: For fatigue-sensitive aerospace and biomedical applications.

Superalloy 3D Printing: For extreme temperature and mechanical loads.

Ceramic 3D Printing: For components requiring dimensional and thermal stability.

Core Post-Processing Treatments:

Hot Isostatic Pressing (HIP): Consolidates structure while eliminating residual stress.

Heat Treatment: Refines mechanical properties for industry compliance.

Precision Finishing Solutions:

CNC Machining: Ensures tolerances are maintained after stress-relief cycles.

Electropolishing: Reduces surface stress concentrators and improves corrosion resistance.